Processing method of reaming

Reaming is a finishing method for holes on the basis of semi-finishing (reaming or semi-finishing boring). The size tolerance of the reaming hole can reach IT9~IT6, and the surface roughness value can reach Ra3.2~0.2μm.

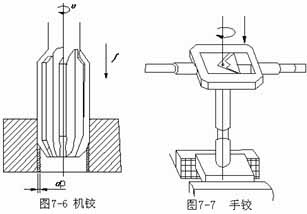

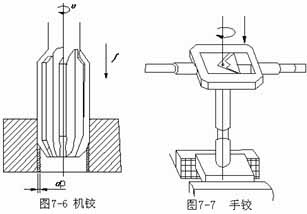

There are two ways of reaming: mechanical reaming and hand reaming. Reaming on the machine tool is called mechanical reaming, as shown in Figure 7-6; Manual reaming is called manual reaming, as shown in Figure 7-7.

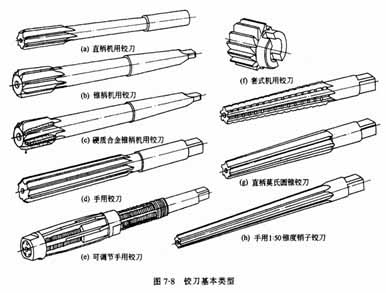

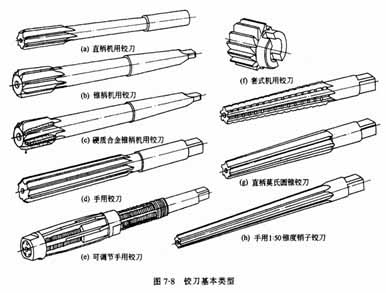

Machine reamer can be divided into shank (1~20mm diameter is straight shank, diameter 10~32mm is taper shank, as shown in Figure 7-8a, b, c) and sleeve type (diameter 25~80mm, such as Shown in Figure 7-8f). Hand reamers can be divided into integral type (as shown in Figure 7-8d) and adjustable type (as shown in Figure 7-8e). Reaming can be used not only to machine cylindrical holes, but also to machine conical holes with a taper reamer (as shown in Figure 7-8g, h).

1. Reaming method

The allowance for the reamed hole of the part is very small. If the margin is too large, the cutting temperature will be high, which will cause the diameter of the reamer to expand and cause the hole diameter to expand, which will increase the amount of chips and scratch the surface of the hole; If the reaming allowance is too small, the tool marks of the original hole will be left and the surface roughness will be affected. Generally, the rough reaming allowance is 0.15~0.25mm, and the fine reaming allowance is 0.05~0.15mm. Reaming should use a low cutting speed, so as not to produce built-up edge and cause vibration. Generally, rough reaming = 4~10m/min, fine reaming = 1.5~5m/min. The feed rate of machine reaming can be 3~4 times higher than that of drilling, generally 0.5~1.5mm/r. In order to dissipate heat and remove chips, reduce friction, suppress vibration and reduce surface roughness, a suitable cutting fluid should be used when reaming holes. Emulsion is often used for reaming steel parts, and kerosene can be used for reaming iron castings.

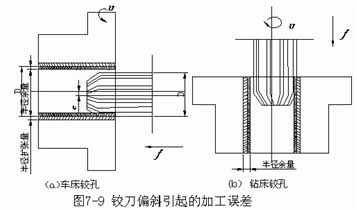

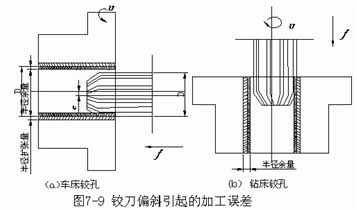

As shown in Figure 7-9a, when reaming on a lathe, if the axis of the reamer installed in the tailstock sleeve is offset from the axis of rotation of the workpiece, it will cause the enlargement of the aperture. As shown in Figure 7-9b, when reaming a hole on a drill press, if the axis of the reamer is offset from the axis of the original hole, it will also cause hole shape errors.

The machine reamer and the machine tool are commonly floating connection to prevent the diameter of the hole from expanding or the shape error of the hole during reaming. The floating chuck used for floating connection between the reamer and the machine tool spindle is shown in Figure 7-10. The taper shank 1 of the floating chuck is installed in the taper hole of the machine tool, the taper shank of the reamer is installed in the taper sleeve 2, the stop pin 3 is used to bear the axial force, and the pin 4 can transmit torque. Because there is a large gap between the tail of the taper sleeve 2 and the large hole, and the pin 4 and the small hole, the reamer is in a floating state.

There are two ways of reaming: mechanical reaming and hand reaming. Reaming on the machine tool is called mechanical reaming, as shown in Figure 7-6; Manual reaming is called manual reaming, as shown in Figure 7-7.

Machine reamer can be divided into shank (1~20mm diameter is straight shank, diameter 10~32mm is taper shank, as shown in Figure 7-8a, b, c) and sleeve type (diameter 25~80mm, such as Shown in Figure 7-8f). Hand reamers can be divided into integral type (as shown in Figure 7-8d) and adjustable type (as shown in Figure 7-8e). Reaming can be used not only to machine cylindrical holes, but also to machine conical holes with a taper reamer (as shown in Figure 7-8g, h).

1. Reaming method

The allowance for the reamed hole of the part is very small. If the margin is too large, the cutting temperature will be high, which will cause the diameter of the reamer to expand and cause the hole diameter to expand, which will increase the amount of chips and scratch the surface of the hole; If the reaming allowance is too small, the tool marks of the original hole will be left and the surface roughness will be affected. Generally, the rough reaming allowance is 0.15~0.25mm, and the fine reaming allowance is 0.05~0.15mm. Reaming should use a low cutting speed, so as not to produce built-up edge and cause vibration. Generally, rough reaming = 4~10m/min, fine reaming = 1.5~5m/min. The feed rate of machine reaming can be 3~4 times higher than that of drilling, generally 0.5~1.5mm/r. In order to dissipate heat and remove chips, reduce friction, suppress vibration and reduce surface roughness, a suitable cutting fluid should be used when reaming holes. Emulsion is often used for reaming steel parts, and kerosene can be used for reaming iron castings.

As shown in Figure 7-9a, when reaming on a lathe, if the axis of the reamer installed in the tailstock sleeve is offset from the axis of rotation of the workpiece, it will cause the enlargement of the aperture. As shown in Figure 7-9b, when reaming a hole on a drill press, if the axis of the reamer is offset from the axis of the original hole, it will also cause hole shape errors.

The machine reamer and the machine tool are commonly floating connection to prevent the diameter of the hole from expanding or the shape error of the hole during reaming. The floating chuck used for floating connection between the reamer and the machine tool spindle is shown in Figure 7-10. The taper shank 1 of the floating chuck is installed in the taper hole of the machine tool, the taper shank of the reamer is installed in the taper sleeve 2, the stop pin 3 is used to bear the axial force, and the pin 4 can transmit torque. Because there is a large gap between the tail of the taper sleeve 2 and the large hole, and the pin 4 and the small hole, the reamer is in a floating state.