Process characteristics of boring

Single-edge boring tool boring has the following characteristics:

(1) The adaptability of boring is strong. Boring can be carried out on the basis of drilling, casting and forging holes. A wide range of achievable dimensional tolerance levels and surface roughness values;

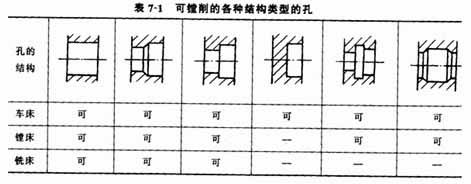

Except for the small and deep holes, almost all holes of various diameters and structures can be bored, as shown in Table 7-1.

(2) Boring can effectively correct the position error of the original hole. However, because the diameter of the boring bar is limited by the hole diameter, its rigidity is generally poor, and it is easy to bend and vibrate. Therefore, the control of boring quality (especially for elongated holes) is not as convenient as reaming.

(3) The productivity of boring is low. Because boring requires multiple passes with a smaller depth of cut and feed to reduce the bending deformation of the tool bar. In addition, boring on boring machines and milling machines requires adjusting the radial position of the boring tool on the tool bar, so the operation is complicated and time-consuming.

(4) Boring is widely used in the hole processing of various parts in single-piece and small-batch production. In mass production, boring the bearing holes of the bracket and box body requires a boring die.

(1) The adaptability of boring is strong. Boring can be carried out on the basis of drilling, casting and forging holes. A wide range of achievable dimensional tolerance levels and surface roughness values;

Except for the small and deep holes, almost all holes of various diameters and structures can be bored, as shown in Table 7-1.

(2) Boring can effectively correct the position error of the original hole. However, because the diameter of the boring bar is limited by the hole diameter, its rigidity is generally poor, and it is easy to bend and vibrate. Therefore, the control of boring quality (especially for elongated holes) is not as convenient as reaming.

(3) The productivity of boring is low. Because boring requires multiple passes with a smaller depth of cut and feed to reduce the bending deformation of the tool bar. In addition, boring on boring machines and milling machines requires adjusting the radial position of the boring tool on the tool bar, so the operation is complicated and time-consuming.

(4) Boring is widely used in the hole processing of various parts in single-piece and small-batch production. In mass production, boring the bearing holes of the bracket and box body requires a boring die.