CNC Machining Cost is How Much

What is the cost of CNC machining? man-hour Quote for CNC machining of different materials (metal, plastic).

First of all, CNC machining costs will vary significantly due to the different CNC machining parts you are doing. Before placing an order, it is necessary to check the overall budget of your project. You must consider several aspects that affect the cost of CNC machining.CNC machining design cost;

The quantity of CNC machining parts;

CNC machining material costs;

The cost of using different types of (Turning, milling) CNC machines;

CNC machining Cost of surface finishes

CNC machining Labor costs

CNC machining Design cost

Various aspects of the design will affect production costs.The complexity of the design will have an impact on this. More complex designs will require more programming time. This will increase the price of your order and CNC Machining Providers will also charge you for the time spent in digital format.

|

|

|

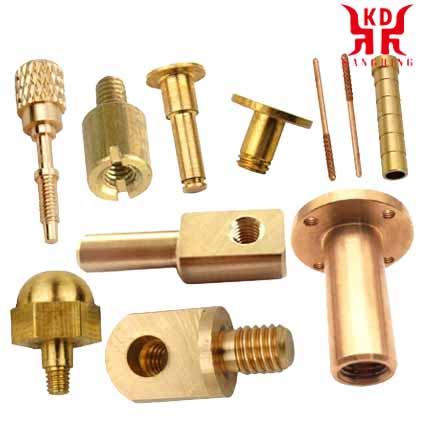

| Machining cost of stainless steel parts | aluminum alloy parts machining cost | Machining cost of copper parts |

The quantity of CNC machining parts;

The amount of your order will also affect the cost that the CNC Service Company charges you.Small orders will be cheaper than large ones. However, larger orders will reduce the cost of each item.

For example, suppose you want to order ten units of CNC machining components. A rapid prototyping company could set a price of $ 15 per unit, which means they must pay a total of $ 150.

However, suppose you have ordered 50 units of CNC precision machining parts, each can cost only $ 5 and you will have to pay a total of $ 250. Yes, although you have to pay an extra $ 100, relatively speaking, you get more products. .

Cost of CNC machining materials

Depending on your product, no matter what you want CNC Plastic Machining Parts or CNC Metal Machining Parts, these CNC machining materials will affect your cost.

In general, plastic will be cheaper than metal because it is not durable and less expensive to produce.

The cost of the material is usually a 6 ″ x 6 ″ x 1 ″ piece.

The price of each piece of common materials used in CNC plastic machining parts are:

The cost of ABS is $ 8 per block

POM (Delrin) charges $ 15 per block

Nylon 6 sells for $ 15 each.

The cost of some popular materials used for CNC machining of metal parts are:

The price of 6061 aluminum , 7075 aluminum CNC machining parts is $ 15 each.

Steel for CNC machining costs $ 25 per piece.

Stainless steel CNC machining services cost $ 30 each.

|

|

|

| 5-axis machining parts quotation | Machining cost of acrylic parts | Machining cost of plastic parts |

The cost of using different types of CNC machines.

You can rent several different types of CNC machines for the project. The one you choose can affect your labor costs.The CNC service company sets the machine rental as an hourly rate. CNC Machining Providers use the price of the machine and how long it can run in one hour each year to calculate this. It is usually calculated by dividing the cost of the machine by 5000.

There are two main types of CNC machines: a 3-axis CNC machine and a multi-axis machine.

How much does CNC machining cost per hour?

3-axis CNC machines include CNC milling machines (operating cost approximately US $ 10 per hour) and CNC turning machines (operating cost approximately US $ 15 per hour).

The multi-axis machine running cost is higher, so the price is higher as well.

Their prices range from $ 25 to $ 40 an hour. Some prices may be higher than this, so you need to ask about your machine selection when getting a quote.

Surface finish cost

For each product, a specific surface treatment for CNC machining components can be carried out. However, the surface finishes of the product tend to increase the corresponding cost.Some surface treatments, such as high polish, aim to remove any trace of the machining process.

E.g:

The surface finish can produce a reflective surface.

Matte surface treatment or sandblasting eliminates reflections.

Mirror polish on clear plastic to look like glass.

Finishing painting and staining may change the color of the product.

Laser engraving can decorate your products.

By printing, you can print letters or patterns on the product after it is finished.

Soft surface treatment involves the application of a soft rubber-like coating over the product.

Some surface treatments play an essential role in making your products last longer. These include galvanized, anodized, and brushed.

Some companies may allow you to combine different finishes on their products. For example, you may be able to get a laser etched glossy polished surface, although this may cost more.

Labor costs

The most significant labor cost found in CNC machining is the initial design and digitization cost. It uses computer software, but it also requires the help of design experts.Especially when your product is complicated, the design time and difficulty will increase. However, regardless of the quality of your order, the design labor costs will remain the same. This means that if you place a large number of orders, your labor costs will drop to less per unit.

Additional labor costs include paying machine operators during production. If your production window is short, then it will be less. Post-processing, finishing, or assembly of parts also requires additional manual labor, which will increase labor costs. That is why it may be cheaper for some projects to outsource manufacturing to a country like China.

In this way, you must weigh your labor costs. Large orders reduce the unit design cost, but the lead time is longer. Therefore, you will have to pay more for the operation of the machine.