3-axis and 5-axis drilling technology for aluminum parts

CNC machining holes in the solid part of the workpiece with a drill is called drilling. The drilling is rough machining, the achievable dimensional tolerance grade is IT13~IT11, and the surface roughness value is Ra50~12.5μm. Due to the long length of the twist drill, the small core diameter and poor rigidity, as well as the influence of the chisel edge, the drilling has the following technological characteristics:

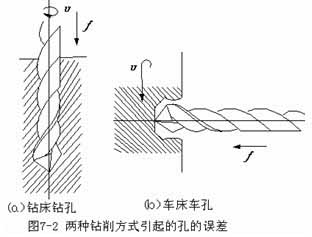

1. The drill bit is easily deflected. Due to the inaccurate centering effect of the chisel edge of the drill, the drill is easy to deflect when cutting in; In addition, the rigidity and guiding effect of the drill bit are poor, and the drill bit is easy to bend during cutting. When drilling on a 3-axis machine tool, as shown in Figure 7-2a, it is easy to cause the axis of the hole to be offset and not straight, but the diameter of the hole does not change significantly; When drilling a hole on a lathe, as shown in Figure 7-2b, it is easy to cause a change in the hole diameter, but the axis of the hole is still straight. Therefore, the end face should be processed before drilling, and a taper pit should be pre-drilled with a drill or a center drill, as shown in Figure 7-3, so that the drill can be centered. When drilling small holes and deep holes, in order to avoid the deviation and non-straightness of the axis of the hole, the workpiece rotation method should be used for drilling as much as possible.

2. The aperture is easy to expand. When drilling, the unequal radial forces of the two cutting edges of the drill will cause the hole diameter to expand; The lead-in deviation when drilling a horizontal lathe is also an important reason for the enlargement of the aperture; In addition, the radial runout of the drill bit is also the cause of the enlargement of the hole diameter.

3. The surface quality of the hole is poor. The drilled chips are wide and are forced to spiral in the hole. When the chips flow out, they rub against the hole wall and scratch the machined surface.

4. Large axial force during drilling. This is mainly caused by the chisel edge of the drill. Tests have shown that 50% of the axial force and 15% of the torque when drilling is generated by the chisel edge. Therefore, when the drilling diameter is d>30mm, the drilling is generally carried out in two times. Drill (0.5~0.7)d for the first time, and drill to the required hole diameter for the second time. Since the chisel edge does not participate in cutting for the second time, a larger feed can be used to improve the surface quality and productivity of the hole.