銑床和銑削技術

銑削是指利用旋轉的多刃刀具切削工件, 是一種高效率的加工方法. 工作時, 工具旋轉 (主要動作), 工件移動 (進給運動). 工件也可固定, 但旋轉工具也必須移動 (同時完成主運動和進給運動). 銑削所用的工具機是水平銑床或立式銑床, 以及大型龍門銑床. 這些工具機可以是普通工具機,也可以是CNC工具機. 使用旋轉銑刀作為切削刀具. 銑削一般在銑床或鏜床上進行. 適合加工平面, 凹槽, 各種成型面 (花鑰匙, 齒輪和螺紋) 以及模具異形表面等.

銑削是一種加工方法,其中銑刀用作工具,並且對象的表面由CNC處理. 銑床包括水平銑床, 垂直銑床, 門戶銑床, 分析銑床, 通用銑床, 和酒吧銑床.

什麼是銑削?

銑削是指利用旋轉的多刃刀具切削工件, 是一種高效率的加工方法. 工作時, 工具旋轉 (主要動作), 工件移動 (進給運動). 工件也可固定, 但旋轉工具也必須移動 (同時完成主運動和進給運動). 銑削所用的工具機是水平銑床或立式銑床, 以及大型龍門銑床. 這些工具機可以是普通工具機,也可以是CNC工具機. 使用旋轉銑刀作為切削刀具. 銑削一般在銑床或鏜床上進行. 適合加工平面, 凹槽, 各種成型面 (花鑰匙, 齒輪和螺紋) 以及模具異形表面等.

銑削工具的功能

①銑削工具的每個牙齒都定期參與間歇性切割.

②切割過程中每個銑刀牙齒的切割厚度.

③每個牙齒αf的進料 (毫米/牙齒) 指示工件旋轉一齒的時間內工件的相對位移.

常見的銑削零件

(1) 扁平零件

平面零件的特徵: 加工表面可以平行於水平面, 垂直於水平面, 或與水平面的固定角度;

CNC銑床上處理的大多數零件都是平坦的零件, 平面零件是CNC銑削中最簡單的零件類型. 一般來說, 只能將三軸連接或三軸連鎖連接到三軸CNC銑床. 在處理過程中, 處理表面和工具處於表面接觸, 以及末端銑刀或球端銑刀可用於粗糙和整理處理.

(2) 特殊形的彎曲表面

彎曲部分的特徵是加工表面是弧形的空間彎曲表面. 機械加工過程中, 加工表面和銑刀總是接觸點. 表面精加工主要使用球端銑削工具進行.

銑床的精密校正

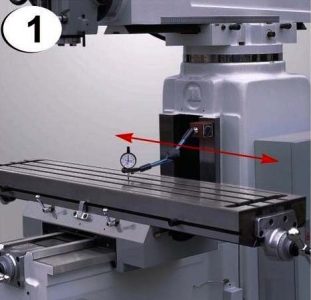

銑床的X軸校正

略微鬆開 4 螺栓, 但是請確保在 4 螺栓. 此時, 使用頭部的旋轉螺栓調節左右角. 在此過程中, 必須在主軸的末端放置一個錶盤指示燈,以測量可工作的正確位置.

Y軸校正銑床

略微鬆開 3 螺栓, 但是請確保 3 螺栓不會太鬆,無法促進微調. 此時, 用手臂旋轉螺栓, 放置在主軸端的撥號指示器,以測量表的正確位置.

水平校正銑床

將精神水平放在工作表面.

檢查級別的A和B, 允許值為0.06mm/m.

如有必要, 可以將墊片放在機器下.

臥式銑床銑削大型鋁合金零件

銑刀和進料量αF的特徵

銑削彎曲的零件和扁平零件的價格計算

X, Y軸和銑床的水平校正

聯絡我們

等待您的電子郵件, 我們將在短時間內回覆您 12 小時提供您所需的有價值的信息.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe