CNC銑削所使用的最佳化是根據銑削零件的特點. 透過對數控銑削零件製程的技術經濟分析與研究, 一個科學的, 建立合理、精準的銑削參數優化數學模型, 並採用適當的最佳化演算法.

銑削量是多少?

隨著現代製造技術的快速發展, 各種複雜成形表面、精度要求高的零件越來越多. As one of the main processing methods of this kind of parts, CNC milling processing. The choice of cutting amount will have a greater impact on processing efficiency, 工具耐用度, processing cost and processing quality.

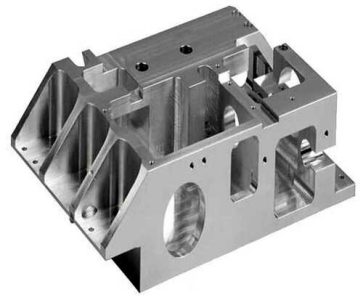

Milling optimization model

Find a set of numerical control milling parameters that minimize the value of the objective function in the feasible area of milling parameters. 所以, the key to the optimization of CNC milling parameters is to establish the numerical relationship between the design variables, the optimization goals, and the constraints, 那是, to establish the optimization mathematical model.

In optimal design, the independent parameters that need to be optimized are called optimal design variables. The cutting parameters such as spindle speed, feed speed, milling thickness, cutting width in CNC milling are the factors that affect the realization of CNC milling goals, and are the basic control quantities in the CNC milling process. There is actually the best combination scheme between them. 所以, in the mathematical model of numerical control milling parameters optimization, the spindle speed n, the feed speed vf, the amount of back tool ap, the cutting width ae, ETC. 被使用. The cutting amount is a design variable.

Milling objective function

The objective function is a function of design variables and an index for comparing and selecting various design schemes. The objective function of numerical control milling parameter optimization should be consistent with the purpose of numerical control milling processing. The purpose of CNC machining is to maximize economic benefits, 那是, through the best combination of cutting parameters, give full play to the cutting efficiency of machine tools and tools, and under the premise of ensuring the quality of processing, reduce processing costs as much as possible and increase productivity. Both processing cost and productivity can establish a functional relationship with the cutting amount. 所以, taking processing cost and productivity as the objective function of numerical control milling consumption optimization is in line with the actual needs of production.

Constraints for milling

The choice of CNC milling amount is limited by technical conditions such as CNC machine tools, 工具, workpieces and processing quality, and the range of cutting amounts available for selection is limited. 所以, 應根據這些限制條件建立數控銑削參數最佳化的限制條件, 使優化結果與實際生產相符.

切削參數多目標最佳化背景

金屬切削加工參數的最佳化選擇對於確保加工品質具有重要意義, 提高生產力和經濟效益. 對於CNC工具機來說也特別重要, 尤其是加工中心. 由於加工過程的複雜性和不確定性, 許多工廠根據經驗選擇切削量, 但實際效果因人而異. 為了控制和保證加工質量, 充分發揮CNC工具機的能源效率, 使切削參數的選擇由經驗判斷轉變為定量分析. 借助電腦技術, 透過簡單可靠的最佳化演算法對切割參數進行最佳化,滿足切割的實際需求.

數控工具機的價格和人力成本較高, 且刀具磨損成本所佔比重較低. 所以, 在大多數材料中, 應盡可能使用高銑削量. 按照這個選擇, 可以降低工具機人工成本在零件製造成本中的比例, 這是正面的一面. 然而, 高切削消耗會降低刀具的耐用度, 需要經常更換或磨銳工具, 從而降低生產力;

切削消耗高,容易產生廢品,降低工具機的可靠性.

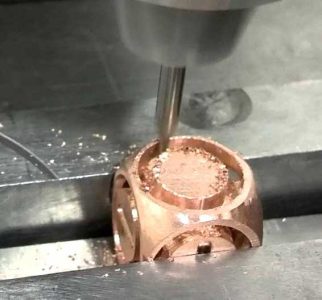

銅量CNC銑削

不銹鋼銑削量

高速銑削量特點

高速銑削切削參數的特點

高進給速度

高速銑削切削參數具有非常高的進給速度. 隨著切削速度的大幅提高:

一方面之間的相對速度, 加速晶片和工具, 工具 - 晶片之間的接觸溫度升高; 晶片底面形成柔軟的滯留層, 減少刀與切屑之間的摩擦係數; 另一方面, 隨著晶片底部和頂部之間的溫差增大, 晶片底部升溫並膨脹, 當切屑流過前刀面時,增加了切屑的彎曲程度. 可以看出,隨著切削速度的增加, 減少了由於第二變形區的摩擦而導致的切屑的額外變形, 由於嚴重的切屑彎曲,刀具與切屑的接觸長度縮短, 因此切屑剪切變形程度減少. 因此, 剪切角增大, 切屑變形減少, 為進給運動速度的提升創造了有利條件.

高銑削速度

高速加工切削消耗有非常高的切削速度, 這通常是 5-10 比普通切割速度高數倍, 主軸轉速可達10000-100000r/min.

聯絡我們

等待您的電子郵件, 我們將在短時間內回覆您 12 小時提供您所需的有價值的信息.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe