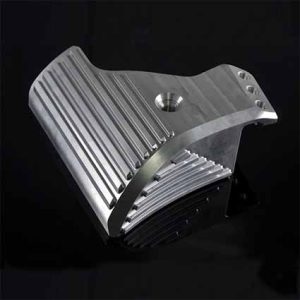

CNC finishing of aluminum alloy parts

CNC Milling a vital role in modern manufacturing.

What is CNC Milling? How does it play a role in manufacturing, and what does CNC machinist do?

數控銑削是一種製造過程,其中預先編程的電腦軟體控制工廠工具和機器的運動. Rapid Prototypes or Production Parts – We have the right CNC Milling options for your plastic or metal part production needs. 此方法可用於控制許多複雜的機器, 從磨床和車床到銑床和銑床. 配備CNC銑床, 可以在一組提示中執行三維切割任務.

Short for “Computer Numerical Control”, the CNC process stands in contrast to the limitations of manual control, which requires live operators to query and guide commands from machining tools via levers, knobs and wheels. To the viewer, a CNC system may resemble a normal set of computer components, but the software programs and consoles used in CNC Milling set it apart from all other forms of computation.

Before NC and CNC Milling

NC machining and later CNC made it possible to control machine tools without the high proportion of manual intervention that had to take place until then to machine a part.

例如, before CNC and NC machining, the drilling of a tube was done by placing the tube in the press of the machine tool to hold it, selecting in this machine the rotation speed of the drill (generally with belt pulleys) and activating the spindle. These actions had a high proportion of manual manipulation (placing the bit on the axis, activating the axis, placing the workpiece under the drill, machining the hole and shutting down the axis), 少量不會造成大問題的東西 , 但由於需要加工更多數量的零件並執行更複雜的加工動作, 由於操作單調而導致人員疲勞的可能性增加, 因此降低了生產力並增加了誤差幅度.

數控加工代表了這個意義上的突破,因為它允許通過穿孔帶控制機床,該穿孔帶包含機器相對於指定切削刀具運動的坐標軸的運動. 這樣, 每一步都不需要人的干預, 他們可以做其他任務, 生產力大提升.

數控前, machining processes had a high component of manual manipulation. Today some isolated operations are carried out manually, with few parts.

Subsequently, this control went from being done with a perforated tape to being done by computer, including the placement of the drill on the shaft, activation, ETC. This had several advantages.

Main advantages of CNC Milling

Improved automation compared to numerical control without a computer: This means that the intervention of the person in each step can be reduced or even eliminated, although some type of manual action always takes place for specific tasks, such as repair and prototyping. That allows for higher production in the same time, since CNC machines are capable of running 24 hours a day.

Greater precision and consistency of the pieces obtained: Today’s CNC machines have astonishing precision and repeatability specifications, with two, ten, or a thousand identical workpieces easily achievable once the program is verified. That was critical in mass production.

Greater flexibility: Being machine tools controlled by a computer program, carrying out a new machining that only contains a few small changes compared to a previous job only requires loading a saved project, making certain changes and saving it separately, as in any other software. This allows quick changes and adaptation to any type of part, and eliminates most prototypes.

Greater security: to have a minimal interaction of the operator with the machine in most of the movements. Previously, when intervening in actions such as changing heads, loading material, stopping a movement, ETC。, there were more chances of having accidents.

Main challenges of CNC Milling

High operating costs: Although CNC machines reduce the number of manual workers required in a manufacturing plant, the machines are more expensive to operate. 然而, the costs associated with running the machines are gradually decreasing.

Training need: 最初, the generalization of CNC Milling led to high unemployment, as the need for manual workers was reduced. 然而, with proper training, this system creates new opportunities for specialized employment. as it requires CNC machine tool operators, programmers, maintenance personnel, as well as machine tool manufacturing engineers and technicians and trainers to teach its operation.

CNC finishing parts

不銹鋼零件的 CNC 精加工

5-軸精加工零件

How CNC Milling Works

Broadly speaking, CNC Milling allows doing practically everything that was previously done manually: placing the drill bit on the axis, activating it, placing the part to be machined on the machine, machining it and turning off the axis. Once the machine tool is configured by CNC and put to work, it requires little intervention from the operators. You can even automate the part loading process.

然而, the task of the operator is still required to make measurement checks and adjustments to keep the CNC machine working properly.

Movement control

Any CNC Milling machine tool allows programming two or more directions of movement (軸, which can be linear-along a straight line- or rotary-along a circular path-). Common linear axis names are X, 是, 和Z. Common rotary axis names are A, 乙, 和C. The more axes the machine has, the more complex it is. In drilling, 三個線性軸將刀具定位在 X 軸和 Y 軸上的零件上要加工的孔上,並使用第三個 Z 軸加工孔.

可編程配件

儘管所有CNC銑床的基本功能都是根據軸控制運動, 真正為每台機器帶來價值的並不是兩個或多個軸上移動零件. 而是它攜帶的可編程配件, 這使得它們的功能倍增.

例如, 加工中心可能具有自動刀具裝載機,無需操作員幹預即可更換切削工具. 如有需要, 您可以選擇刀具並自動將其放置在主軸上進行加工, 或對軸速度和主軸激活進行編程, or the coolant to lubricate and cool the part that can be turned on and off from within of the machine cycle.

CNC finishing of copper parts

With the CNC Milling system, a part is machined using the following steps:

1) Design of the conceived part: use CAD software to create a 2D or 3D model of the part.

2) CNC programming: use CAM software to convert CAD model to g-code. G-Code is the language used to program CNC machines, which can be edited from a normal text manager (Notepad, Word) or a specialized program.

3) CNC machine setup: In this step, the machine is setup by clamping, suitable tools and G-code editing program (by DNC system), and the tool data is loaded to prepare the machine to machine the part. The operator will also tell the machine where the zero point is to start.

4) CNC Milling of the part: 以上所有準備就緒, 是時候開始加工零件了.

CNC Milling allows doing practically everything that was previously done manually: placing the drill bit on the axis, activating it, placing the part to be machined on the machine, machining it and turning off the axis.

金屬工業和數控銑削

數控銑削徹底改變了金屬產業, 對其經濟潛力產生決定性影響, 以更低的成本實現更高的產量. 基本上我們可以區分金屬產業內的三大群體,它們以數控銑床為主要工作系統:

金屬加工業: 許多行業需要鋼板等薄板用於各種用途, 這些板材是在製造業中加工的. 通常使用進行切割等各種操作的CNC工具機, 火焰或等離子切割, 沖孔, 雷射切割, 輪廓加工和焊接以及許多其他應用.

這個行業是幾十年前最常使用的手動機器之一 (沖孔機, 圓盤切割機, 壓力機, ETC。) 但如今,這些相同機器的 CNC 版本已全面擴展並廣泛使用.

醫用植入鈦合金腔體

Rapid Prototypes or Production Parts - We have the right CNC Milling options for your plastic or metal part production needs.

材料範圍廣

滿足最嚴格的公差要求

直接根據 3D CAD 模型加工零件

標準交貨時間之間 1 和 2 週, 取決於訂單

交貨時間可能會更短 (2 到 5 工作日), 取決於可用容量

細部尺寸公差:

標準: +/- 0.005

最低限度: +/- 0.002 對於金屬和 +/- 0.003 用於塑膠

孔徑公差:

標準: +/- 0.005

最低限度: +/- 0.001 對於金屬和 +/- 0.002 用於塑膠

平面度公差, 偏心率, 圓柱度, 垂直度和其他幾何形狀:

標準: +/- 0.005

最低限度: +/- 0.001, 取決於幾何形狀

當加工焊接組件或板材小於 1/4 "厚且大於 20" 厚的, 或者 1/8 "厚超過 10" 長度. 在這些情況下, 製造團隊需要審查公差.

CNC Milling is a subtractive manufacturing process whereby material is trimmed from the origin to create a finished component. Our standard surface finish is 63 到 125 Rms. 然而, we can grind or polish the part to between 4 和 8 Rms.

Shot blasting

Electropolished

熱處理

噴砂

Steam polishing

優勢

Send us your 3D CAD data by email, indicate the specifications of your project and we will present you with a personalized quote in less than 24 小時

車削, dual revolver lathe with rotary machining, 3-, 4- and 5-axis machining, stress attenuation / heat treatment, 焊接, anodizing and powder coating

CNC machined parts in as little as 6-8 工作日 (取決於幾何形狀)

Dedicated project managers to help you throughout the entire process

聯絡我們

等待您的電子郵件, 我們將在短時間內回覆您 12 小時提供您所需的有價值的信息.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe