單刃鏜刀鏜孔具有以下特點:

(1) 鏜孔適應性強. 在鑽孔的基礎上可以進行鏜孔, 鑄鍛孔. 可實現的尺寸公差水平和表面粗糙度值範圍廣泛;

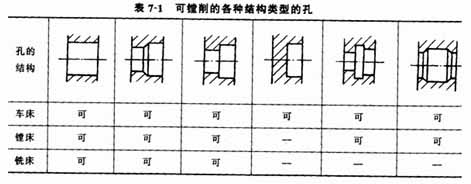

除了小而深的洞, 幾乎所有各種直徑和結構的孔都可以鑽, 如表所示 7-1.

(2) 鏜孔可有效修正原孔的位置誤差. 然而, 因為鏜桿的直徑受到孔徑的限制, 其剛性普遍較差, 而且很容易彎曲和振動. 所以, 鏜孔品質的控制 (特別適用於長孔) 不如鉸孔那麼方便.

(3) 鏜孔生產率低. 因為鏜孔需要以較小的切削深度和進給量多次走刀,以減少刀桿的彎曲變形. 另外, 在鏜床和銑床上鏜孔需要調整鏜刀在刀桿上的徑向位置, 所以操作複雜且耗時.

(4) 鏜孔廣泛應用於單件、小批量生產中各種零件的孔加工. 量產中, 支架和箱體軸承孔的鏜削需要鏜模.

鏜孔的特點

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe