關鍵字: CNC machining of mold cores, CNC加工

The core and cavity of the mold often have various free-form surfaces, which are very suitable for processing on CNC machine tools. The process of CNC machining is quite different from the ordinary process. This article combines the NC machining process design of the mold core of children’s product decorations, analyzes and summarizes the process characteristics of the mold NC machining, and provides a reference for the NC process design of the mold.

The CNC machining process refers to the sum of various methods and technical means used when machining parts with CNC machine tools, which is applied to the entire CNC machining process. Because CNC machining has the characteristics of high processing efficiency, 品質穩定, 對工人技術要求相對較低, 一次裝夾即可完成複雜曲面的加工. 所以, CNC加工在模具製造業的應用越來越廣泛, 而其地位也越來越重要. CNC製程設計的好壞將直接影響CNC加工尺寸的尺寸精度和表面質量, 加工時間長度, 材料和勞力的消耗, 甚至直接影響機械加工的安全. 以下舉例分析典型模具成型零件的CNC加工工藝.

1. 產品分析

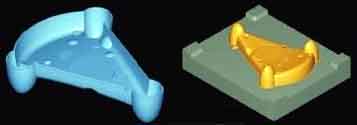

本文範例的產品為兒童用品裝飾品, 且材質是ABS. 從產品圖片可以看出 (數位 1) that the product has a relatively simple structure, with a flat surface, semi-circular holes on the side and multiple round holes on the top. Since the product is an ornament and is not a precise structural part, the appearance quality of the product is higher, and the dimensional tolerance is not strict.

CNC machining of mold cores

2. Structure and analysis of molded parts

After obtaining the solid modeling or engineering drawing of the product, the mold can be designed using the CAD function in Pro/ENGINEER, NX or MasterCAM. The designed mold core is shown in Figure 2.

The mold core has the following characteristics:

(1) The size of the core blank is 200×170×65mm, the size after processing is 160.8×126.6×35.8mm, and the material is S136 steel.

(2) The height of the core glue position of the mold is 35.8mm, 橢圓面與三角形面相交處的圓角較小, 僅R1mm. 這些位置用銑刀直接加工比較困難, 並可採用放電加工來滿足要求.

由於產品的尺寸公差不高, 鐵芯可直接用CNC工具機加工.

3. 製程分析

CNC加工技術與傳統加工技術有一定的差別. 由於大多數CNC工具機不具備加工能力, 加工過程的每個細節都必須事先確定, 並依照編好的程序自動完成加工. 所以, 編程前必須詳細分析加工工藝, 並設計相應的加工程序.

兒童ABS裝飾製品

(1). 工藝基準選擇

CNC加工大多採用工序集中的原則. 所以, 選擇流程基準時, 應盡可能選擇合適的基準元件,減少裝夾次數,提高加工效率和加工精度;

同時, 選擇定位基準時, 必須參考圖面要求,使製程基準與設計基準重合,減少因基準不重合而產生的誤差.

在這個例子中, 工件毛坯磨削後為長方體毛坯. 平行性, 垂直度和尺寸精度得到保證. 所以, 水平方向可選擇長和寬的相對邊作為參考 (XY方向); 高度方向可選擇底面為參考 (Z方向). 同時, 在機床上找到一對刀具基準,確保編程的高度基準, 為工件座標系的Z0點, 更換工具後仍能準確找到. CNC加工過程中不再加工這些基準面, 作為加工基準可以保證基準的準確性和統一性.

(2). 夾緊方式的選擇

銑削過程中, 工件的夾緊方式一般有壓板夾緊和螺栓夾緊, 用機用扁嘴鉗夾緊, 並用專用夾具夾緊. The mold core is a one-piece production order, and special fixtures are generally not used; The size of the mold core is 200×170×65mm, which is a small workpiece. 所以, machine flat-nose pliers are selected for clamping. When using machine flat-nose pliers, the height of the core is 35.8mm. 所以, the height of the top surface of the blank from the jaws of the flat-nose pliers after clamping should be greater than 35.8mm, and the bottom surface can be cushioned with a contour pad.

Milling processing sequence

(3). Processing sequence arrangement

Parts processed on CNC machine tools are generally divided into processes according to the principle of process concentration, 那是, each process should include as much processing content as possible. The process division methods are divided according to the used tools, divided according to the number of installations, divided according to rough and fine machining or divided according to the processing position. This example is a mold core, which belongs to single-piece production. 所以, process concentration is the principle when arranging the processing sequence to reduce the number of tool changes and improve processing efficiency.

Whether the processing sequence is arranged reasonably, directly affects the processing quality, processing efficiency and processing cost. When selecting the processing sequence, it is necessary to combine the positioning reference and clamping method of the part according to the rough condition and the part structure. The key points need to be considered to ensure that the rigidity of the workpiece is not damaged during processing, reduce deformation, 並保證加工品質.

模芯毛坯材料為長方體, 且產品成分面切削量大. 必須先進行粗加工, 然後完成半精加工和精加工. 分型面加工後, 頂面, 接觸面及塗膠位置依序完成.

(4). 工具選擇

刀具的選擇是CNC加工過程中的重要內容之一. 加工刀具不僅影響工具機的加工效率, 也直接影響零件的加工品質. 因為CNC工具機的主軸轉速和幅度遠高於一般工具機, 且主軸的輸出功率比較大. 所以, 與傳統加工方法相比, 對數控加工刀具提出了更高的要求, 需要高精度的, 高強度, 剛性好、耐久性高, 要求尺寸穩定、安裝調整方便. 數控刀具是提高加工效率的先決條件之一. 其選擇取決於加工零件的幾何形狀, 物質條件, 工具機的夾具和所選刀具的剛性.

模芯材質為S136鋼, 硬度約220HB;

扁嘴鉗用於毛坯夾緊, 提供足夠的剛性. 所以, 硬質合金銑刀用於加工此芯部. 工具參數如下:

(1) 直徑30mm,半徑5mm的圓刀;

(2) 圓頭刀,直徑16mm,半徑0.5mm;

(3) 半徑5mm的球頭刀;

(4) 直徑8mm平底立銑刀.

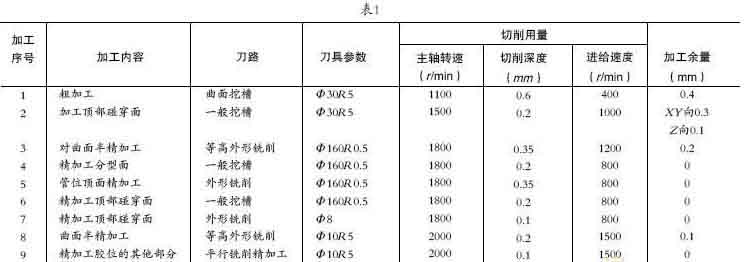

4. 基於MaterCAM的CNC加工工藝

MaterCAM軟體是基於PC平台的CAD/CAM系統. 因為它對硬體要求不高, 操作靈活, 易學易用, 廣泛應用於機械加工, 模具製造, 汽車工業和航空航天工業. 具有二維幾何設計功能, 三維曲面設計, 刀具路徑模擬與加工實體模擬. 本例使用MasterCAM 9.1 用於刀具路徑編程. 處理順序見表 1.

以上處理步驟均經過實際處理驗證, 證明處理效果良好, 且尺寸精度和表面加工品質符合圖面要求.

5. 分析總結

(1) 數控工具機在加工複雜曲面模塑零件方面優勢明顯. 只要工藝設計合理, 多於 80% 可以完成的處理量.

(2) 模具的CNC加工一般是快速原型小批量生產. 所以, 通用夾具通常用於夾緊, 一次裝夾完成多道工序. 所以, 在工藝設計中, 應採用工藝集中的原則,使工藝盡可能集中. 同時, 盡量減少換刀次數,減少待機時間,提高工具機利用率.

(3) 模具成型零件一般可透過三道工序完成: rough machining → semi-finishing → finishing. In process design, attention must be paid to the selection of positioning datum, try to ensure the coincidence of positioning datum and design datum, and reduce errors caused by inconsistent datums. 同時, the choice of positioning reference should make the setting of the workpiece coordinate system simple.

(4) When selecting a tool, comprehensive consideration should be given to many factors such as the machine tool, workpiece material and design requirements. The setting of tool parameters should be based on the parameters improved by the tool manufacturer, and corresponding modifications should be made according to the processing conditions to maximize the potential of the tool. On the premise of ensuring that the tool does not interfere with the workpiece, 盡量縮短刀具長度以減少刀具振動, 延長刀具壽命, 並提高加工精度.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe