使用短切割工具是五軸加工的主要功能. 短工具將大大減少工具偏差, 從而獲得良好的表面質量, 避免返工, 減少使用的焊接量, 並縮短EDM的處理時間. 考慮五軸加工時, 必須考慮使用五軸加工模具的目標:

使用可能的最短切割工具來完成整個工件的處理. 它還包括減少編程, 夾緊和處理時間,但可以獲得更完美的表面質量.

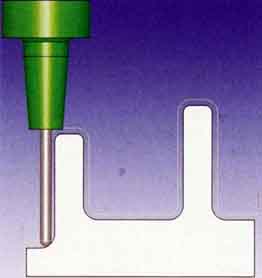

只要工件腔不是很深 (相對於工具直徑), 三軸工具路徑 (2, 3, 5) 足夠了. 如果工件腔非常深,並且零件非常狹窄, 使用純的三軸工具路徑來完成整個整個完成還不足. 在這種情況下, 表面質量差,隨之而來的處理時間很長. 數位 1 是三軸工具路徑的情況. 這裡, 最短的工具必須很長,才能在垂直方向上加工工件的所有區域.

3-短工具的軸加工路徑

數位 1, 三軸加工路徑

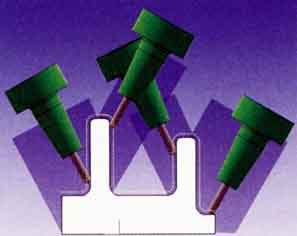

使用較短工具時, 主軸應傾斜,以確保可以處理工件的特殊區域. 3+2 軸加工通常被認為是與主軸設定恆定角度. 複雜的工件可能需要許多傾斜的視圖才能覆蓋整個工件, 但這將導致工具路徑重疊並增加加工時間.

另外, 所有的傾斜視圖都難以準確結合, 因此,手動拋光的工作量將增加, 同時, 它將大大增加進出的運動, 這通常會導致表面質量問題和更多的工具運動.

數位 2, 3+2 軸工具通道, 以這種方式進行編程將互相干擾,並且耗時, 而且所有視圖的總和通常無法覆蓋整個幾何形狀. 數位 2 展示四個工件景色, 但是工件中心仍然有一個無法覆蓋的區域. 該區域仍然需要額外的傾斜視圖.

3+2 軸短工具加工路徑

數位 3, 5-軸工具路徑

5-軸短工具加工路徑

為了克服缺點 3+2 軸加工, 五軸聯動加工可能是更好的選擇, 更何況有些五軸工具機還具有一些專為模具產業設計的功能. 五軸聯動加工,可協調三個直線軸和兩個旋轉軸,使其同時運動, 它解決了3軸和3軸的所有問題 3+2 軸加工. 該工具可以很短, 沒有觀點重疊, 丟失加工區域的可能性較小, 並且可以連續處理,無需額外的進出口 (見圖 3).

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe