銑削不銹鋼的特點是: 不銹鋼具有很強的附著力和熔合力, 而且切屑容易黏附在銑刀的刀齒上, 這使得銑削條件變得更差;

逆銑時, 刀齒首先在硬化表面上滑動, 這增加了加工硬化的趨勢; 銑削時, 衝擊、振動大, 使得銑刀的刀齒容易崩刃和磨損.

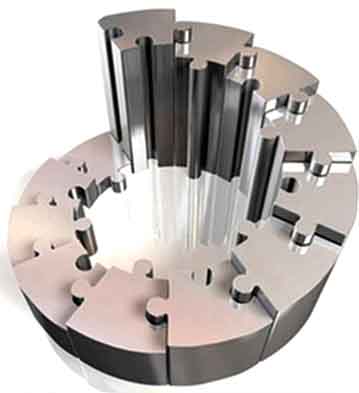

精密不銹鋼零件數控銑削

For milling stainless steel, in addition to end mills and some end mills, cemented carbide can be used as milling cutter tooth materials. Other types of milling cutters are made of high-speed steel, especially tungsten-molybdenum series and high-vanadium high-speed steel with good results. The tool durability can be 1-2 times higher than W18Cr4V. Cemented carbide grades suitable for making stainless steel milling cutters are YG8, YW2, 813, 798, YS2T, YS30, YS25, ETC.

When milling stainless steel, the milling edge must be sharp and able to withstand impact, and the chip pocket must be large. Large helix angle milling cutters (cylindrical milling cutters, end milling cutters) can be used, the helix angle b is increased from 20° to 45° (gn=5°), and the tool durability can be increased by more than 2 次. Because the working rake angle g0e of the milling cutter is increased from 11° to more than 27° at this time, the milling is brisk. But the value of b should not be too large, especially for end mills with b≤35°, so as not to weaken the teeth.

Using wave-edge end mills to process stainless steel pipes or thin-walled parts, cutting is brisk, vibration is small, chips are fragile, and the workpiece is not deformed. High-speed milling with cemented carbide end mills and stainless steel with indexable end mills can achieve good results.

Quick quotation for machined parts

Milling 1Cr18Ni9Ti with silver chip end mill (SWC), its geometric parameters are gf=5°, gp=15°, af=15°, ap=5°, kr=55°, k′r=35°, g01= -30°, bg=0.4mm, re=6mm. When Vc=50-90m/min, Vf=630-750mm/min, a′p=2-6mm, and the feed per tooth reaches 0.4-0.8mm, the milling force is reduced by 10%-15%, and the milling power A reduction of 44%, efficiency has also been greatly improved. 原理是在主切削刃上磨出負倒角, 並在銑削過程中人為地產生積屑瘤, 從而可以代替切削刃進行切削, 積屑瘤前角gb可達20~-302. 由於主偏角的影響, 積屑瘤受到前刀面上產生的平行於切割刃的推力,成為流出的二次切屑, 從而帶走切削熱,降低切削溫度.

When milling stainless steel, 應盡可能採用順銑. 非對稱順銑方法可確保切削刃順利地切離金屬, 且晶片鍵合接觸面積小, 在高速離心力的作用下容易被甩落. 為了防止刀齒重新切入工件時切屑衝擊前刀面, 會發生剝落和碎裂, 並且可以提高刀具的耐用度.

噴霧冷卻法是最有效的, 可使銑刀的耐用度提高一倍以上; 如果一個將軍 10% 乳化液用於冷卻, 應確保切削液流量以達到充分冷卻. 當硬質合金銑刀銑削不銹鋼時, 取Vc=70-150m/min,Vf=37.5-150mm/min. 同時, 根據合金牌號和工件材料進行適當調整. 高速鋼銑刀切削量如表 1

| 銑刀類型 | 銑刀直徑d0 (毫米) |

主軸轉速n (轉速) |

進給量f (毫米/分鐘) |

評論 |

| 立銑刀 | 3-4 | 1180-750 | 手動的 | 當切削寬度和切削深度較小時, 進給量f取大值; 相反, 銑削2Cr13等小值馬氏體不鏽鋼時, 銑削量應根據工件材料的實際硬度進行調整 銑削耐濃硝酸不銹鋼時, 應適當降低銑削速度和進給量 |

| 5-6 | 750-475 | |||

| 8-10 | 600-375 | |||

| 12-14 | 375-235 | 30-37.5 | ||

| 16-18 | 300-235 | 37.5-47.5 | ||

| 20-25 | 235-190 | 47.5-60 | ||

| 32-36 | 190-150 | 47.5-60 | ||

| 40-50 | 150-118 | 47.5-75 | ||

| 波刃立銑刀 | 36 | 190-150 | 47.5-60 | |

| 40 | 150-118 | |||

| 50 | 118-95 | |||

| 60 | 95-75 | 60-75 | ||

| 鋸片銑刀和麵銑刀 | 75 | 235-150 | 23.5 或手動 | |

| 110 | 150-75 | |||

| 150 | 95-60 | |||

| 200 | 75-37.5 |

桌子 1, 高速鋼銑刀加工不銹鋼的銑削量

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe