造成鋁構件變形的原因有很多, 與材料有關的, 處理工具, 零件的形狀, 以及加工設備. 主要有以下幾個方面: 毛坯內應力引起的變形, 由切削力和切削熱引起的變形, 以及夾緊力引起的變形.

一, 減少加工變形的製程措施

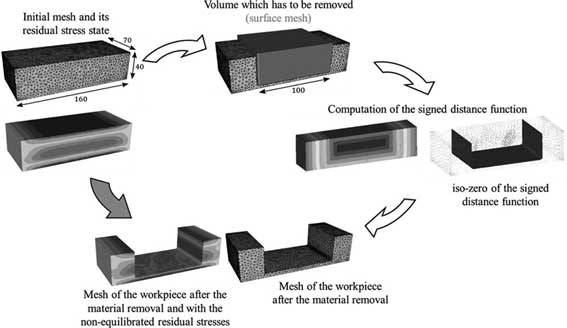

1. 降低鋁坯內應力

自然或人工時效及振動處理可部分消除毛坯內應力. 前處理也是一種有效的處理方法. 對於大毛坯, 由於利潤率大, 加工後變形也大. 若事先加工毛坯多餘部分,並減少各部分的餘裕, 可減少後續工序的加工變形. 而且, 經過預處理並放置一段時間後, 也可釋放部分內應力.

鋁件銑削變形的原因

2. 提高刀具的切削能力

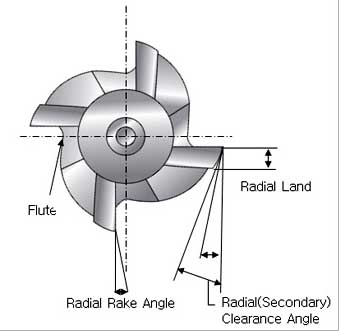

刀具的材料和幾何參數對切削力和切削熱有重要影響. 正確選擇刀具對於減少零件變形至關重要.

(1) 合理選擇刀具幾何參數.

① 刀具的前角: 在保持刀刃強度的情況下, 前角應適當大一些. 一方面, 它可以磨削鋒利的切割刃, 另一方面, 可以減少切削變形, 使排屑順利, 然後降低切削力和切削溫度. 切勿使用負前角刀具.

② 刀具後角: 後角的大小直接影響後刀面的磨損和加工表面的質量. 切削厚度是選擇後角的重要條件. 粗銑時, 由於進給量大, 切削負荷大、發熱大, 要求工具有良好的散熱條件. 所以, 後角應小一些. 精銑時, 要求切割刃鋒利, 減少後刀面與加工表面之間的摩擦, 並減少彈性變形. 所以, 後角的角度應選大一些.

③刀具螺旋角: 為了使銑削順利並減少銑削力, 螺旋角應選擇盡可能大的.

④刀具主偏角:

適當減小刀具主偏角,可改善散熱條件,降低加工區域的平均溫度.

銑刀切削能力

(2) 完善工具結構.

①減少銑刀齒數,增加容屑空間. 由於鋁材的可塑性大, 加工時切削變形大, 並且需要更大的晶片容量空間, 因此容屑槽的底部半徑應較大,銑刀齒數應較少.

② 細磨牙齒. 刀齒刃口粗糙度值應小於Ra=0.4um. 使用新刀之前, 磨刀時應使用細油石輕輕打磨刀齒的前後,以消除殘留的毛邊和輕微的鋸齒。. 這樣, 不僅可以降低切削熱, 而且切削變形也比較小.

③ 嚴格控製刀具磨損標準. 工具磨損後, 工件表面粗糙度值增加, 切削溫度升高, 且工件變形增大. 所以, 除了選擇耐磨性好的刀具材料外, 刀具磨損標準應不大於0.2mm, 否則容易產生積屑瘤. 切割時, 工件溫度一般不超過100℃,以防變形.

銑刀幾何參數

3. 改進工件裝夾方法

適用於剛性差的薄壁鋁工件, 可採用以下裝夾方法來減少變形:

① 對於薄壁襯套零件, 如果使用三爪自定心卡盤或彈簧卡盤從徑向夾緊, 一旦處理後釋放, 工件不可避免地會變形. 此時, 應採用剛性較好的軸向端面壓緊方法. 定位零件的內孔, 自製一個穿過心軸的螺紋, 將其套入零件的內孔中, 用蓋板壓住端面,然後用螺帽旋緊. 外圓加工時可避免裝夾變形, 從而獲得滿意的加工精度.

② 加工薄壁、薄板型腔工件時, 最好使用真空吸盤以獲得均勻分佈的夾緊力, 然後以較小的切削量進行加工, 可以很好的防止工件變形.

另外, 也可以採用打包的方法. 為了增加薄壁工件的加工剛性, 可在工件內部填充介質,減少工件裝夾、切削時的變形. 例如, 倒入含有尿素熔體 3% 到 6% 硝酸鉀進入工件, 以及處理後的, 將工件浸入水或酒精中,使填料溶解並倒出.

三爪自定心卡盤

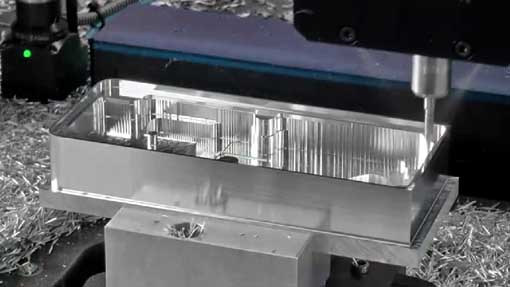

4. 合理安排加工工序

高速切削時, 由於加工餘量大、斷續切削, 銑削過程經常產生振動, 影響加工精度和表面粗糙度. 所以, CNC高速切削加工一般可分為: 粗加工-半精加工-清角加工-精加工等工序. 對於精度要求高的零件, 有時需要進行二次半精加工,然後進行精加工. 粗加工後, 零件可自然冷卻,消除粗加工產生的內應力,減少變形. 粗加工後留下的餘量應大於變形量, 一般來說 1 到 2 毫米. 整理過程中, 零件的精加工表面應保持均勻的加工餘裕, 一般0.2-0.5mm為宜, 使刀具在加工過程中處於穩定狀態. 可大幅減少切削變形, 獲得良好的表面加工質量, 並確保產品精度.

鋁件高速切削

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe