Elektrotun kavisli yüzeyi işlenmiştir, ve ardından ince duvarlı şekil CNC ile tamamlanır. If the contour is machined first and then the top surface is machined, the thin-walled shape is too high at this time. Under the action of the cutting force of the tool, the top of the copper electrode is often deformed and bent, causing machining failure. This is also the most likely problem in the machining of thin electrodes. Aynı zamanda, because there are 5.0mm narrow grooves between the thin slices, only a small diameter tool can be used to finish the shape of the thin slices. Öyleyse, the diameter of the end mill is 4.0mm, the speed is 2000r/min, and the feed speed νf=400mm/min. When finishing the curved surface and then machining the electrode shape, it should be noted that the cutting depth should not be too large each time, the tool diameter is small, and the clamping length is longer (larger than the electrode height, take 26.0mm). Öyleyse, it is easy to produce overcutting; The cutting thickness of each layer is only 0.4mm; The speed and feed rate should be higher to achieve a certain efficiency.

1. Setting of specific CNC machining path

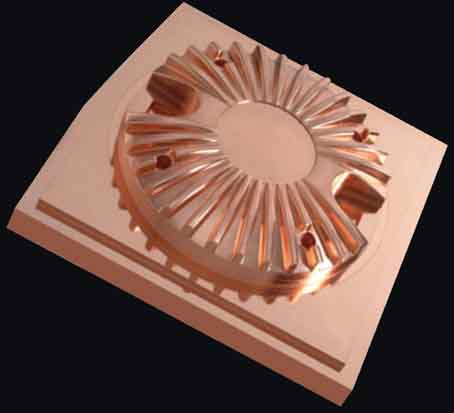

The specific CNC plus path parameter settings are shown in the figure.

Aralarında, the shape machining allowance parameter (XY stock to leave) takes-0.1mm, which is the spark machining gap reserved for the electrode. The tool lift selection parameter (Keeptool down) is selected to not lift the tool, because the tool is lowered outside the contour and the tool is determined to be at a safe empty position, so there is no need to set the tool lift. In order to save the empty running time of the tool and improve the efficiency.

2. Trajectory planning of CNC machining process

The machining process planning of the curved thin-walled electrode has a decisive effect on the success or failure of the machining. The same CMC processing method and parameter settings are carried out in different processing sequences, and the results obtained are completely different. Process plan: rough milling shape, processing frame → contour roughing of curved surface → finishing of curved surface → thin-walled shape of finishing.

Elektrotun yüzeyini CNC bitirme

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe