Prototip CNC işleme çok çeşitli malzemeleri işleyebilir. Plastik malzemeler: ABS'ler, PMMA, PP, bilgisayar, POM, naylon, bakalit, vesaire. Metal malzemeler şunları içerir:: alüminyum, magnezyum ve çinko alaşımları, bakır, çelik, ütü, titanyum, vesaire. Karşılanabilecek birçok CNC prototip türü vardır, ve şu anda Çin'de yaygın olarak kullanılıyorlar.

The current prototype processing methods mainly include cnc processing, 3d printing, complex mold, sla, sls and so on. But the cnc prototype still occupies half of the prototype industry, this is mainly because cnc prototype has its unique advantages. Mainly reflected in the following aspects:

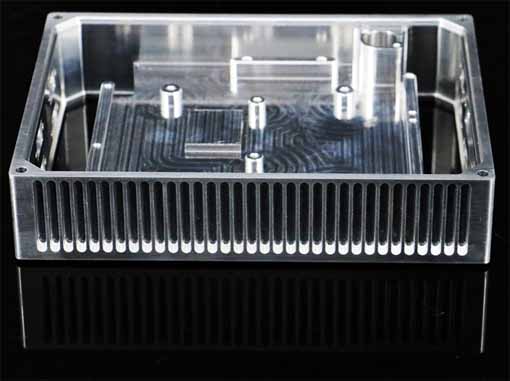

The prototype CNC machining system can control the machine tool to automatically select and change tools according to different procedures. Automatically change the machine tool spindle speed, feed rate and the motion path of the tool relative to the workpiece and other auxiliary functions to complete the multi-process processing on several surfaces of the workpiece in sequence. The entire processing process is automatically controlled by the program, and is not affected by the operator’s human factors, and automatic processing is realized.

The advantages of CNC machining prototypes are: multi-coordinate linkage (3 eksen, 4 eksen, 5 eksen), and complex shape prototypes can be processed. When machining parts are changed, generally only the NC program needs to be changed, which can save production preparation time. The machine tool itself has high processing precision and high rigidity, and can choose favorable processing amount, Yüksek verimlilik; mass production, easy to control product quality. The machine tool has a high degree of automation, which can reduce labor intensity. Have stable prototype processing quality.

1. The production efficiency is high, the programming software is fast in calculation speed, and the machine tool has the ability of high precision and high speed, so it can greatly improve the production efficiency.

2. Higher accuracy. The accuracy of general CNC machining centers can reach 0.1 mm. The equipment used by our company is currently more advanced, and its accuracy can reach 0.05~0.1mm. The smaller the product volume, the higher the accuracy of the product.

3. Many parts that can’t be processed or difficult to be processed by ordinary machine tools can be processed. Örneğin: Complicated curve parts described by three-dimensional space surface parts and mathematical models.

4. The high degree of automation enables operators to reduce a lot of burdens. Many prototype operators can operate two machines by one person, and some can even operate three machines at the same time, which also reduces the labor cost of the enterprise.

5. Strong adaptability and flexibility. It can process parts with particularly complex contour shapes or difficult to control size, which is difficult to achieve like other processing methods.

Prototip CNC İşleme

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe