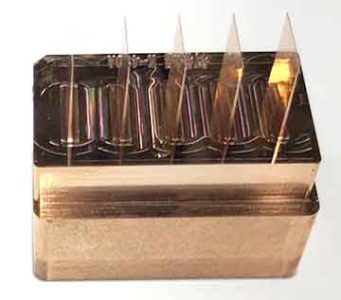

CNC-bearbetning av kopparelektrod

The copper electrode of the EDM machine, Also known as CNC machining of copper electrode mirror. It is an indispensable part in the processing of EDM machine.

Under EDM-bearbetning, kopparelektroden och arbetsstycket är anslutna till de två polerna på pulsströmförsörjningen. Pulsspänningen som appliceras på kopparelektroden och arbetsstycket genererar gnisturladdning. Den momentana temperaturen på urladdningen kan vara så hög som 10,000 grader Celsius, och den höga temperaturen gör att arbetsstyckets yta delvis förångas eller smälter.

Kopparelektrod av EDM-maskin

Immediately after the next pulse voltage, a spark discharge is generated between the copper electrode and the workpiece, and the above process is repeated.

Through countless repetitive pulse discharges, a shape corresponding to the shape of the electrode is finally processed. Därför, as long as the shape of the copper electrode is changed, various complicated profiles can be processed.

In EDM machining, the role of the copper electrode is to transmit processing pulses and to remove the workpiece with the minimum loss of the copper electrode itself. Commonly used electrode materials are copper, graphite, copper-tungsten alloy, silver-tungsten alloy, stål, mässing, cast iron, etc.

Mirror copper electrode

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe