Set the geometric parameters of turning and milling titanium tools to improve the product quality of titanium alloy parts. Products are delivered quickly and on time.

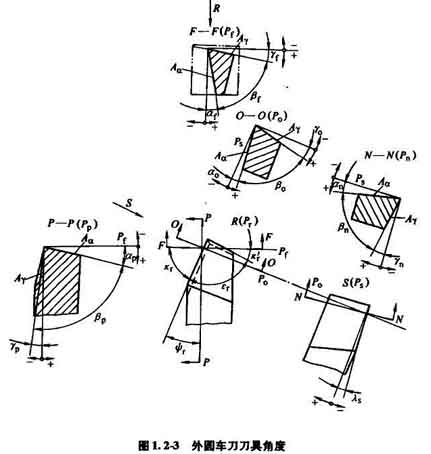

(1) The rake angle of the tool γ0: The contact length between titanium alloy chips and the rake face is short. When the rake angle is small, the contact area of the chip can be increased, so that the cutting heat and cutting force are not excessively concentrated near the cutting edge. Improve the heat dissipation conditions, and can strengthen the cutting edge and reduce the possibility of chipping. Turning titanium generally takes γ0=5°~15°.

(2) The clearance angle α0 of the tool: The processed surface of titanium alloy has large elastic recovery and serious cold hardening. The use of a large relief angle can reduce the friction, adhesion, adhesion, tearing and other phenomena caused to the flank surface, so as to reduce the wear of the flank surface. The relief angle of various cutting titanium alloy tools is basically greater than or equal to 15°.

(3) The leading deflection angle κr and the secondary deflection angle κ´r of the milling tool: When milling titanium alloys, the cutting temperature is high and the elastic deformation tends to be large. When the rigidity of the process system allows, the entering angle should be reduced as much as possible to increase the heat dissipation area of the cutting part and reduce the load per unit length of the cutting edge. Vo všeobecnosti, κr=30° is used, and κr=45° for rough machining. Reducing the secondary deflection angle can strengthen the tool tip, which is beneficial to heat dissipation and reduces the surface roughness value of the machined surface. Generally take κ´r =10°~15°.

(4) The blade inclination angle of the tool λs: Due to the rough surface and uneven surface structure of the blank, the cutting edge is prone to chipping during rough turning. In order to increase the strength and sharpness of the cutting edge, the sliding speed of the chip should be increased. Vo všeobecnosti, λs = -3°~-5° is used for rough turning, and λs = O° for fine turning.

(5) The radius of the nose arc of the tool rε: When turning titanium alloy, the tool tip is the weakest part, which is easy to chip and wear, so it needs to grind the tool tip arc. Generally rε=0.5~1.5mm.

Negative chamfering (bγ=0.03~0.05 mm, γ01=-10°~0°) is used during turning, and the arc radius of the bottom of the chip flute is Rn=6~8 mm.

Navyše, the quality of tool sharpening is also very important to improve its durability. Carbide cutting tools should be sharpened with diamond grinding wheels. The cutting edge must be sharp when cutting, the surface roughness Ra value of the front and rear cutting faces should be less than 0.4um, and the cutting edge is not allowed to have tiny gaps. After the tool is sharpened and ground, its durability can be increased by 30%.

Design of cutting edge angle for turning and milling titanium

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe