Kategórie produktov

Štítky produktu

Čo je tlakové liatie hliníka?

Tlakové liatie hliníka sa vzťahuje na hliníkové časti z čistého hliníka alebo zliatiny hliníka získané odlievaním. Vo všeobecnosti, piesková forma alebo kovová forma sa používa na naliatie zahriateho tekutého hliníka alebo hliníkovej zliatiny do dutiny formy, a získané hliníkové diely alebo diely z hliníkovej zliatiny rôznych tvarov a veľkostí sa zvyčajne nazývajú hliníkové odliatky.

Tlakové liatie hliníka sa vzťahuje na hliníkové časti z čistého hliníka alebo zliatiny hliníka získané odlievaním. Vo všeobecnosti, piesková forma alebo kovová forma sa používa na naliatie zahriateho tekutého hliníka alebo hliníkovej zliatiny do dutiny formy, a získané hliníkové diely alebo diely z hliníkovej zliatiny rôznych tvarov a veľkostí sa zvyčajne nazývajú hliníkové odliatky.

Technológia tlakového liatia hliníka

Aluminum casting is a modern molding technology

The complex casting of aluminum castings is a kind of low pressure casting technology with electromagnetic pump as the core. The composite purification technology of aluminum smelting and molding is a new technology at the core of the aluminum die-casting industry, a modern technology for producing high-quality aluminum castings. The electromagnetic pump low pressure casting molten metal transmission system has a stable flow and convenient flow control. The advantage of alleviating the suction process of molten alumina and easy realization is the automation of the use process, which not only improves the casting quality of aluminum castings, but also improves the working environment. Reduce labor intensity, realize automation and modern casting production.

Dôležitou súčasťou čistenia odliatkov z roztavených smaltovaných zliatin sú okrem vstrekovania plynu a rotačných penových keramických filtrov s vysokým odplyňovaním aj zariadenia na tavenie hliníka a čistenie kompozitov., pokiaľ výkon kovových inklúzií. Navyše, používa nový podšívkový materiál s dlhou životnosťou a má nezávislý systém uchovania/ohrievania tepla, ktorý možno použiť pre veľké množstvo nepretržitej výroby, ako aj prerušovaná výroba. Technológia čistenia roztaveného hliníka tejto technológie je vysoko účinná, dlhý život, nízke náklady, efektívne, jednoduchá inštalácia, použitie a flexibilné. Skúsenosti s odlievaním nám hovoria, že kvalita hliníkových odliatkov na riešenie zložitých problémov spočíva v troch hlavných aspektoch:

(1) Tavenie a tavenie roztaveného hliníka,

(2) Smooth transition of molten aluminum metal halide lamp

(3) The size and stability of the mold and sand core process.

Core manufacturing process modeling can see that casting quality and output have a direct impact. Casting porosity, sticky sand, scars, thermal cracking, surface quality, dimensional accuracy, and sand performance have a very good relationship. The new technology for modeling and manufacturing is PEPSET. The core resin binder used in the original zirconium sand sand has an independent, non-hardening chemical reaction mechanism initially from hard sand to hard sand. It's time to start hardening, once the curing reaction starts fast. In a tough, vysoká pevnosť, gas fat collapse small, good performance is the complexity of the casting surface, dimensional accuracy and quality stability.

Performance and application of aluminum die casting

Cast aluminum alloy has some advantages that other castings cannot match, such as beautiful appearance, light weight, odolnosť proti korózii, atď., making it widely favored by users. Especially since the lightweight of automobiles, cast aluminum alloy castings have been widely used in the automobile industry.

The density of cast aluminum alloy is lower than that of cast iron and cast steel, but its specific strength is higher. Preto, the use of aluminum alloy castings under the same load conditions can reduce the weight of the structure. Preto, aluminum alloy castings are widely used in the aviation industry, power machinery and transportation machinery manufacturing. Aluminum alloy has good surface gloss and good corrosion resistance in the atmosphere and fresh water, má teda široké využitie pri výrobe civilného náradia. Čistý hliník má dobrú odolnosť proti korózii v oxidačných kyslých médiách, ako je kyselina dusičná a kyselina octová, takže hliníkové odliatky majú určité využitie aj v chemickom priemysle. Čistý hliník a hliníkové zliatiny majú dobrú tepelnú vodivosť. Používajú sa v zariadeniach na výmenu tepla používaných v chemickej výrobe, a časti, ktoré vyžadujú dobrú tepelnú vodivosť na energetických strojoch. Napríklad, hlavy valcov a piesty spaľovacích motorov sú vhodné aj na výrobu hliníkovej zliatiny.

Hliníková zliatina má dobré odlievacie vlastnosti. Kvôli nízkemu bodu topenia (teplota topenia čistého hliníka je 660,230C, teplota odlievania hliníkovej zliatiny je všeobecne asi 730-750 °C). It can be widely used type of metal casting and pressure casting and other methods to increase the intrinsic quality of the casting, the degree of dimensional accuracy and surface finish and productivity. Due to the high latent heat of solidification of aluminum alloy, the solidification process of molten aluminum lasts much longer than cast steel and cast iron under the same weight. It has good liquidity and is conducive to casting thin-walled and complex-structured castings.

Cast aluminum alloy castings have many advantages, making it one of the most popular casting products for the development direction of the casting industry and purchasing customers. In the future, with the advancement of aluminum alloy casting technology, it will show its style on a larger stage.

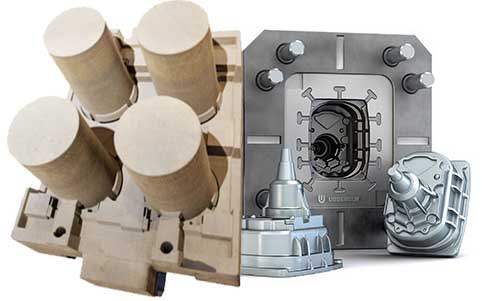

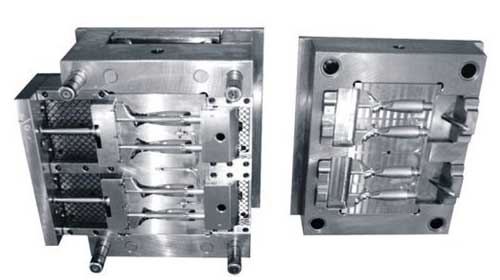

Piesková forma alebo kovová forma na tlakové liatie hliníka

Tlaková forma na tlakové liatie hliníka

Odliatky z horčíkovej zliatiny

Analysis of urgent problems to be solved in the future development of domestic aluminum alloy casting industry

Reducing energy consumption, reducing environmental pollution and saving limited resources is a very important and urgent task facing all countries today. Driven by the general trend of lightweight products such as automobiles, it can be predicted that my country's light metal casting market will have a substantial development in the next 10 years. The proportion of aluminum and magnesium alloy castings in the major casting production countries is between 13% a 19%, and some countries (such as Italy) are as high as 30% do 40%. The proportion of aluminum and magnesium alloy castings in my country is less than 10%. More than 90% of aluminum castings in developed countries are used in automobile parts manufacturing. In my country, there are still many problems to be solved for aluminum alloy castings to form large-scale production and meet the requirements of automobile lightweight:

najprv, automotive requirements for aluminum castings are developing towards thin-walled, complex shapes, vysoká pevnosť, and high quality. To meet this requirement, the casting process should be further optimized and new alloy materials should be developed.

Second, the production cost should be reduced from the perspective of design and process. Napríklad, use one-mold multi-part technology and automation technology to improve productivity, extend mold life, and use integrated design to reduce the number of parts.

Third, use computer simulation technology to shorten the development cycle of the process plan.

Fourth, increase the recovery of aluminum. Recyklovaný hliník je hlavnou surovinou na odlievanie hliníka. Pri rozvoji zlievarenského priemyslu, naša krajina by mala venovať pozornosť využívaniu zdrojov recyklovaného hliníka, vyvinúť technológie na efektívne oddelenie hliníka od kompozitných a odlišných materiálov, a zaviesť širokú škálu systémov recyklácie odpadu.

Kontaktuj nás

Čaká sa na váš e-mail, odpovieme vám v rámci 12 hodiny s cennými informáciami, ktoré ste potrebovali.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe