Категории продукта

Теги продукта

Недавние Посты

токарная обработка прецизионных деталей из различных материалов

Различные токарные материалы (алюминиевый сплав, нержавеющая сталь, медь, титановый сплав) иметь разные настройки компенсации ошибок. Современные технологии машиностроения развиваются в направлении высокой эффективности., высокое качество, высокая точность, высокая интеграция и высокий интеллект. Технология прецизионной и сверхточной обработки стала важнейшей составляющей и направлением развития современного машиностроения., и это стало ключевой технологией для повышения международной конкурентоспособности.. Благодаря широкому применению прецизионной обработки, ошибки токарной обработки стали горячей темой исследований. Поскольку тепловая и геометрическая погрешности занимают подавляющее большинство различных погрешностей станка, уменьшение этих двух ошибок, особенно тепловая ошибка, стало главной целью.

Различные токарные материалы (алюминиевый сплав, нержавеющая сталь, медь, титановый сплав) иметь разные настройки компенсации ошибок. Современные технологии машиностроения развиваются в направлении высокой эффективности., высокое качество, высокая точность, высокая интеграция и высокий интеллект. Технология прецизионной и сверхточной обработки стала важнейшей составляющей и направлением развития современного машиностроения., и это стало ключевой технологией для повышения международной конкурентоспособности.. Благодаря широкому применению прецизионной обработки, ошибки токарной обработки стали горячей темой исследований. Поскольку тепловая и геометрическая погрешности занимают подавляющее большинство различных погрешностей станка, уменьшение этих двух ошибок, особенно тепловая ошибка, стало главной целью.

Error compensation technology (ECT for short) has emerged and developed with the continuous development of science and technology. The loss caused by the thermal deformation of the machine tool is considerable. Поэтому, it is extremely necessary to develop a high-precision, low-cost thermal error compensation system that can meet the actual production requirements of the factory to correct the thermal error between the spindle (or workpiece) and the cutting tool. In order to improve the machining accuracy of machine tools, reduce waste, increase production efficiency and economic benefits.

Basic definition of turning error compensation

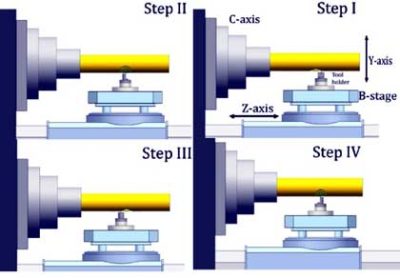

The basic definition of error compensation is to artificially create a new error to offset or greatly reduce the original error that is currently a problem. Through analysis, statistics, induction and mastering the characteristics and laws of the original error, the error mathematical model is established. Try to make the artificial error and the original error have the same value and opposite direction, so as to reduce the processing error and improve the dimensional accuracy of the part.

The earliest error compensation was realized by hardware. Hardware compensation is mechanical fixed compensation. To change the compensation amount when the machine tool error changes, it is necessary to re-make parts, correct the ruler or re-adjust the compensation mechanism. Hardware compensation has the disadvantages of not being able to solve random errors and lack of flexibility. The characteristic of the developed software compensation is to comprehensively use the advanced technology and computer control technology of various disciplines to improve the machining accuracy of the machine tool without any changes to the machine tool itself. Software compensation overcomes many difficulties and shortcomings of hardware compensation and pushes the compensation technology to a new stage.

Error compensation characteristics of different turning materials

Error compensation (технологии) has two main characteristics: scientific and engineering.

The rapid development of scientific error compensation technology has greatly enriched precision mechanical design theory, precision measurement and the entire precision engineering, and has become an important branch of this discipline. The technologies related to error compensation include detection technology, sensing technology, signal processing technology, photoelectric technology, material technology, computer technology and control technology. As a new technology branch, error compensation technology has its own independent content and characteristics. Further research on error compensation technology to make it theorized and systematized will have very important scientific significance.

The engineering meaning of engineering error compensation technology is very significant, it contains three meanings:

One is that the use of error compensation technology can easily achieve the accuracy level that "hard technology" can cost a lot to achieve; The second is to use error compensation technology, which can solve the accuracy level that "hard technology" usually cannot achieve; The third is that if error compensation technology is adopted under the condition of meeting certain accuracy requirements, the cost of instrument and equipment manufacturing can be greatly reduced, and it has very significant economic benefits.

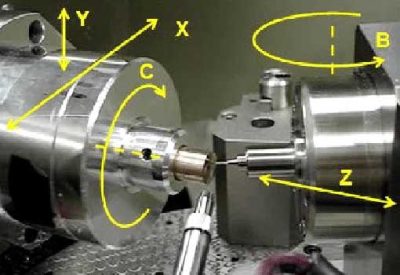

The generation and classification of thermal errors in turning

With the further improvement of machine tool accuracy requirements, the proportion of thermal error in the total error will continue to increase, and the thermal deformation of machine tools has become a major obstacle to improving machining accuracy. The thermal error of the machine tool is mainly caused by the thermal deformation of the machine tool components caused by the internal and external heat sources of the machine tool such as motors, bearings, transmission parts, hydraulic systems, ambient temperature, and coolant. The geometric error of the machine tool comes from the manufacturing defects of the machine tool, the fit error between the machine parts, the dynamic and static displacement of the machine parts, и так далее.

Basic method of error compensation

In summary and related references, it can be known that turning machining errors are generally caused by the following factors:

Thermal deformation error of machine tool;

Geometric errors of machine tool parts and structures;

Error caused by cutting force;

Turning tool wear error;

Other error sources, such as the servo error of the machine tool axis system, the numerical control interpolation algorithm error, и т. д..

There are two basic methods to improve the accuracy of machine tools: error prevention method and error compensation method. The error prevention method attempts to eliminate or reduce possible sources of error through design and manufacturing methods. The error prevention method is effective to reduce the temperature rise of the heat source, balance the temperature field and reduce the thermal deformation of the machine tool to a certain extent. But it is impossible to completely eliminate thermal deformation, and the cost is very expensive; The application of thermal error compensation law opens up an effective and economical way to improve the accuracy of machine tools.

Related conclusions

The research of turning machining errors is the most important part and development direction in modern machinery manufacturing, и это стало ключевой технологией для повышения международной конкурентоспособности.. Errors are multifaceted, and the analysis and research of thermal errors is helpful to improve turning accuracy and technical requirements.

The error compensation technology can meet the high precision and low cost of the actual production requirements of the factory. Thermal error compensation technology can correct the thermal drift error between the spindle (or workpiece) and the cutting tool, improve the machining accuracy of the machine tool, reduce waste, increase production efficiency and economic benefits.

Error Compensation Technology of Turning Titanium Alloy Parts Precision

Error compensation technology for turning copper parts

Error compensation technology for turning stainless steel parts

Error compensation technology for turning aluminum parts

Технология токарно-механического производства

Связаться с нами

Жду вашего письма, мы ответим вам в течение 12 часы с ценной информацией, которая вам нужна.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe