Категории продукта

Теги продукта

Недавние Посты

Фрезерные услуги с ЧПУ в Китае

Фрезерование с ЧПУ — это производственный процесс, в котором предварительно запрограммированное компьютерное программное обеспечение управляет движением заводских инструментов и машин.. Быстрые прототипы или производственные детали. У нас есть подходящие варианты фрезерования с ЧПУ для ваших нужд в производстве пластиковых или металлических деталей.. Метод может быть использован для управления рядом сложных машин., от шлифовальных и токарных станков до фрез и фрезерных станков. С фрезерным станком с ЧПУ, задачи трехмерной резки можно выполнять с помощью одного набора подсказок.

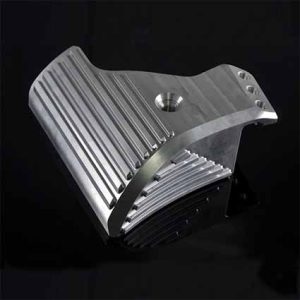

CNC finishing of aluminum alloy parts

CNC Milling a vital role in modern manufacturing.

What is CNC Milling? How does it play a role in manufacturing, and what does CNC machinist do?

Фрезерование с ЧПУ — это производственный процесс, в котором предварительно запрограммированное компьютерное программное обеспечение управляет движением заводских инструментов и машин.. Rapid Prototypes or Production Parts – We have the right CNC Milling options for your plastic or metal part production needs. Метод может быть использован для управления рядом сложных машин., от шлифовальных и токарных станков до фрез и фрезерных станков. С фрезерным станком с ЧПУ, задачи трехмерной резки можно выполнять с помощью одного набора подсказок.

Short for “Computer Numerical Control”, the CNC process stands in contrast to the limitations of manual control, which requires live operators to query and guide commands from machining tools via levers, knobs and wheels. To the viewer, a CNC system may resemble a normal set of computer components, but the software programs and consoles used in CNC Milling set it apart from all other forms of computation.

Before NC and CNC Milling

NC machining and later CNC made it possible to control machine tools without the high proportion of manual intervention that had to take place until then to machine a part.

Например, before CNC and NC machining, the drilling of a tube was done by placing the tube in the press of the machine tool to hold it, selecting in this machine the rotation speed of the drill (generally with belt pulleys) and activating the spindle. These actions had a high proportion of manual manipulation (placing the bit on the axis, activating the axis, placing the workpiece under the drill, machining the hole and shutting down the axis), something that did not pose major problems with small quantities , but as it was required to machine a greater number of parts and carry out more complex machining actions, the probability of fatigue of the person due to the tedium of the operation increased, and therefore decreased productivity and increased the margin of error.

NC machining represented a breakthrough in this sense because it allowed the machine tool to be controlled by means of a perforated belt containing the movements of the machine in relation to the coordinate axes that specified the movement of the cutting tool. Таким образом, the intervention of the person was not needed at each step, they could do other tasks, and productivity was greatly increased.

Before numerical control, machining processes had a high component of manual manipulation. Today some isolated operations are carried out manually, with few parts.

Subsequently, this control went from being done with a perforated tape to being done by computer, including the placement of the drill on the shaft, activation, и т. д.. This had several advantages.

Main advantages of CNC Milling

Improved automation compared to numerical control without a computer: This means that the intervention of the person in each step can be reduced or even eliminated, although some type of manual action always takes place for specific tasks, such as repair and prototyping. That allows for higher production in the same time, since CNC machines are capable of running 24 hours a day.

Greater precision and consistency of the pieces obtained: Today’s CNC machines have astonishing precision and repeatability specifications, with two, ten, or a thousand identical workpieces easily achievable once the program is verified. That was critical in mass production.

Greater flexibility: Being machine tools controlled by a computer program, carrying out a new machining that only contains a few small changes compared to a previous job only requires loading a saved project, making certain changes and saving it separately, as in any other software. This allows quick changes and adaptation to any type of part, and eliminates most prototypes.

Greater security: to have a minimal interaction of the operator with the machine in most of the movements. Previously, when intervening in actions such as changing heads, loading material, stopping a movement, и т. д., there were more chances of having accidents.

Main challenges of CNC Milling

High operating costs: Although CNC machines reduce the number of manual workers required in a manufacturing plant, the machines are more expensive to operate. Однако, the costs associated with running the machines are gradually decreasing.

Training need: Initially, the generalization of CNC Milling led to high unemployment, as the need for manual workers was reduced. Однако, with proper training, this system creates new opportunities for specialized employment. as it requires CNC machine tool operators, programmers, maintenance personnel, as well as machine tool manufacturing engineers and technicians and trainers to teach its operation.

CNC finishing parts

ЧПУ-обработка деталей из нержавеющей стали

5-детали для отделки осей

How CNC Milling Works

Broadly speaking, CNC Milling allows doing practically everything that was previously done manually: placing the drill bit on the axis, activating it, placing the part to be machined on the machine, machining it and turning off the axis. Once the machine tool is configured by CNC and put to work, it requires little intervention from the operators. You can even automate the part loading process.

Однако, the task of the operator is still required to make measurement checks and adjustments to keep the CNC machine working properly.

Movement control

Any CNC Milling machine tool allows programming two or more directions of movement (axes, which can be linear-along a straight line- or rotary-along a circular path-). Common linear axis names are X, Да, и З. Common rotary axis names are A, Б, and C. The more axes the machine has, the more complex it is. In drilling, the three linear axes would position the tool over the hole to be machined in the part on the X and Y axes and would machine the hole with the third Z axis.

Programmable accessories

Although the fundamental function that all CNC Milling machines have is to control movement according to axes, what really gives value to each machine is not moving the part in two or more axes. but rather the programmable accessories that it carries, which make them multiply their functions.

Например, a machining center may have an automatic tool loader to change the cutting instrument without operator intervention. and if necessary, you can choose the tool and automatically place it on the spindle for machining, or programming the axis speed and spindle activation, or the coolant to lubricate and cool the part that can be turned on and off from within of the machine cycle.

CNC finishing of copper parts

With the CNC Milling system, a part is machined using the following steps:

1) Design of the conceived part: use CAD software to create a 2D or 3D model of the part.

2) CNC programming: use CAM software to convert CAD model to g-code. G-Code is the language used to program CNC machines, which can be edited from a normal text manager (Notepad, Word) or a specialized program.

3) CNC machine setup: In this step, the machine is setup by clamping, suitable tools and G-code editing program (by DNC system), and the tool data is loaded to prepare the machine to machine the part. The operator will also tell the machine where the zero point is to start.

4) CNC Milling of the part: with all the above ready, it is time to start machining the part.

CNC Milling allows doing practically everything that was previously done manually: placing the drill bit on the axis, activating it, placing the part to be machined on the machine, machining it and turning off the axis.

Metal industry and CNC Milling

CNC Milling has revolutionized the metal industry, decisively influencing its economic potential, with higher production at lower cost. Basically we can distinguish three large groups within the metal industry that make CNC Milling machine tools their main work system:

Metal fabrication industry: Thin plates such as steel plates are required in many industries for various purposes, and such plates are machined in the manufacturing industry. generally with CNC machines that carry out various operations such as cutting, flame or plasma cutting, пробиться, laser cutting, contouring and welding and many other applications.

This industry was one of the most used manual machines decades ago (punching machines, disc cutting machines, presses, и т. д.) but today the CNC versions of these same machines are fully extended and are used in a majority way.

Medical implant titanium alloy cavity

Rapid Prototypes or Production Parts - We have the right CNC Milling options for your plastic or metal part production needs.

Wide range of materials

Meet the Tightest Tolerances

Machining parts directly from 3D CAD models

Standard delivery time between 1 и 2 weeks, depending on the order

Delivery times may be shorter (2 к 5 рабочие дни), depending on available capacity

Tolerances for the size of the details:

Стандартный: +/- 0.005

Minimum: +/- 0.002 for metal and +/- 0.003 for plastic

Tolerances for hole diameter:

Стандартный: +/- 0.005

Minimum: +/- 0.001 for metal and +/- 0.002 for plastic

Tolerances for flatness, eccentricity, cylindricity, perpendicularity and other geometries:

Стандартный: +/- 0.005

Minimum: +/- 0.001, depending on geometry

The above tolerances do not apply when machining welded assemblies or plates less than 1/4 "thick and greater than 20" thick, или 1/8 "thick with more than 10" length. In these cases, the MFG team will need to review the tolerances.

CNC Milling is a subtractive manufacturing process whereby material is trimmed from the origin to create a finished component. Our standard surface finish is 63 к 125 Rms. Однако, we can grind or polish the part to between 4 и 8 Rms.

Shot blasting

Electropolished

Термическая обработка

Sandblasting

Steam polishing

Преимущество

Send us your 3D CAD data by email, indicate the specifications of your project and we will present you with a personalized quote in less than 24 часы

Поворот, dual revolver lathe with rotary machining, 3-, 4- and 5-axis machining, stress attenuation / термическая обработка, сварка, anodizing and powder coating

CNC machined parts in as little as 6-8 рабочие дни (depending on geometry)

Dedicated project managers to help you throughout the entire process

Связаться с нами

Жду вашего письма, мы ответим вам в течение 12 часы с ценной информацией, которая вам нужна.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe