Потому что при пятиосном высокоскоростном фрезеровании траектория инструмента усложняется., и вектор оси инструмента часто меняется в процессе обработки.. Особенно при высокоскоростной резке, скорость движения инструмента очень высокая, поэтому очень важно провести проверку и проверку программы ЧПУ перед фактической обработкой изделия с ЧПУ..

Due to the five-axis linkage high-speed cutting, the program volume is large. Many programs adopt manual methods or simulate in CAM software, which is difficult to effectively check whether there is a problem with the actual output of the CNC program and the machine tool. Using Vericut software can save time for proofreading and perform real simulation processing. Vericut software can simulate the interference, over-cutting, advance and retreat of the tool during the machining process, especially the 5-axis machining and its RTCP function. Vericut provides many functions, among which there is a complete graphic display of the size, position and orientation of the blank, which can simulate the milling and drilling processing of 2~5 axis linkage.

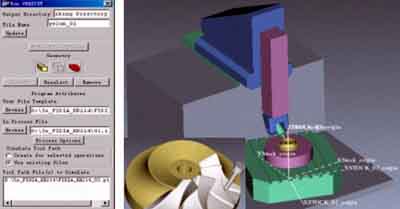

UGII / Vericut cutting simulation module is a third-party module integrated in UGII software. It uses human-computer interaction to simulate, inspect and display NC machining programs, which is a convenient way to verify NC programs. As the trial cut sample is omitted, the machine debugging time can be saved, tool wear and machine cleaning work can be reduced. By defining the blank shape of the cut part and calling the NC tool location file data, the correctness of the tool path generated by the NC can be verified. UGII/Vericut can display the processed and colored part model, and the user can easily check the incorrect processing situation.

As another part of the inspection, the module can also calculate the volume of the processed parts and the amount of blank removal. The digital model in UGII can be directly transferred to Vericut software for simulation, including digital information such as blanks, products, CNC tool paths and tools. Фигура 9 shows the Vericut interface interface provided under the UGNX environment. The simulation situation in Vericut software when processing a certain integral impeller machine tool provides a better inspection process to ensure the quality of the product.

Моделирование траектории 5-осевого высокоскоростного фрезерования

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe