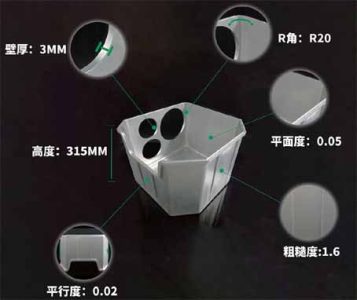

Полость из алюминиевого сплава используется в аэрокосмической продукции.. Параметры фрезерования (трудность): высота изделия 315мм, внутренний R20, плоскостность 0.05, параллелизм 0.02, шероховатость 1.6.

Алюминиевая полость представляет собой оболочку аэрокосмического компонента, изготовленную по заказу компании-производителя аэрокосмической продукции.. Алюминиевая полость представляет собой высокоточную и сложную полость для фрезерования с ЧПУ.. Глубина обработки достигает 315 мм., а требования к точности параллельности и плоскостности очень высоки. Так как я подписал с клиентом договор о неразглашении, подробности не будут описываться снова.

Наименование товара: Aluminum cavity used in military industry

Метод обработки: CNC milling of aluminum alloy cavity

Материал: алюминиевый сплав

Обработка поверхности: полировка, удаление заусенцев, окисление

Цикл обработки: 3-7 семь рабочих дней

Стандарт тестирования: 3Чертежи D предоставлены заказчиком

Формат данных: СТП/ИГС/Х.Т/ПРО

Особенности продукта: гладкая поверхность, глянцевый, тонкая работа

Difficulties of CNC milling aluminum cavity

Обработка на станке с ЧПУ алюминиевой полости, используемой в авиации

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe