Categorias de Produtos

Etiquetas de produto

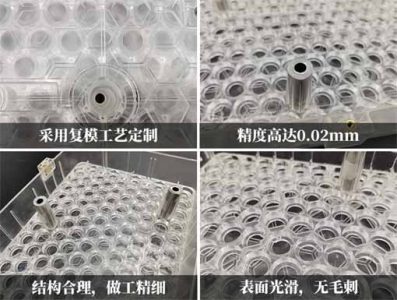

Fabricante de protótipo de fundição em molde a vácuo

Silicone vacuum casting prototype manufacturer

Replicated products adopt materials: PU doméstico, PU importado, PU transparente, PU macio, Saigang, abdômen, PP, PC ABS resistente a altas temperaturas, etc..

Os materiais usados para fazer moldes de silicone são: gel de sílica doméstico, sílica gel importada, sílica gel transparente, e sílica gel especial.

The composite mold refers to the use of the original prototype to make a silicone mold in a vacuum state. And use PU material for pouring under vacuum. So as to clone the same copy as the original template.

This technology greatly reduces the development cost, cycle and risk of the product due to its fast speed and low cost.

Os materiais usados para fazer moldes de silicone são: gel de sílica doméstico, sílica gel importada, sílica gel transparente, e sílica gel especial.

Replicated products adopt materials: PU doméstico, PU importado, PU transparente, PU macio, Saigang, abdômen, PP, PC ABS resistente a altas temperaturas, etc..

1. Prototype production: According to the 3D drawings provided by the customer, the prototype is produced through CNC machining, SLA laser rapid prototyping or 3D printing.

2. Casting silicone mold: After making the prototype, make the mold base, fix the prototype, pour the silicone, and after 8 hours of drying, open the mold and take out the prototype, and the silicone mold is completed.

3. Vacuum injection: inject the liquid gum material into the silicone mold. After curing for 30-60 minutes in a 60°-70° incubator, the mold can be demolded. Se necessário, perform secondary curing for 2-3 hours in a 70°-80° incubator. sob circunstâncias normais, the service life of silicone molds is 15-20 vezes.

Vacuum injection molding machine, also known as vacuum compound molding machine, is suitable for rapid prototyping, copying and production of small batch plastic parts.

Vacuum injection molding is a small batch product manufacturing process by pouring polyurethane material in a silicone mold. Product material properties are similar to engineering plastics. The surface finish, color, product size and mechanical properties of the product obtained by vacuum injection molding can be similar to those of steel injection molded products. When the customer needs 1-100 samples, and the construction period and cost do not allow the injection mold to be opened directly, vacuum injection molding is the most ideal solution.

The vacuum casting machine can be used for silicone rubber molds and polyurethane molds. Vacuum casting of small batches of injection molded parts. It is widely used in product development and small batch production in industries such as automobiles, eletrodomésticos, light industry, medical treatment, agricultural machinery and military industry.

Numbering project technical parameters

Vacuum injection molding machine model: V550, V650, V850, V1000, V1200, V1200S, V1200-JC, V2000, V2500

1. Injection capacity (g) 1000, 2500-15000

2. Mold size: 550*500*450(milímetros), 650*600*550(milímetros) 850*750*800(milímetros), 1000*800*780(milímetros), 1200*950*820(milímetros), 1200 *2000*820(milímetros), 2000*1200*1000(milímetros), 2500*1200*100(milímetros)

3. Vacuum degree can reach: ≤-97 to -100 (Kpa)

4. Vacuum volume: 40 (m3/h), 65 (m3/h), 100 (m3/h), 100 (m3/h), 200 (m3/h), 300 (m3/h), 200+ 300 (m3/h), 300+300 (m3/h)

5. Vacuum time ≤ 3 (Mínimo), ≤ 3 (Mínimo), ≤ 3 (Mínimo), ≤ 3 (Mínimo)

6. Deflation time (adjustable) ≤20 (Sec), ≤50 (Sec)

7. Vacuum pressure holding time≤2(Kpa/H)≤2(Kpa/H)≤3(Kpa/H)≤5(Kpa/H)

8. Pouring method (optional) manual / electric

9. Input power AC 380V/50Hz, AC 380V/50Hz, AC 380V/50Hz, AC 380V/50Hz

10. Power of the whole machine 1 (Kw), 2 (Kw), 5 (Kw), 6 (Kw)

11. Equipment weight 500 (Kg), 1000 (Kg), 1500 (Kg), 3400 (Kg)

Produtos de fundição a vácuo de molde composto de silicone

Silicone overmolded battery cell holder box

Silicone overmolded abs shell

Contate-nos

Aguardando seu e-mail, responderemos dentro de 12 horas com informações valiosas que você precisava.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe