Product Categories

Product Tags

control the precision of milled parts

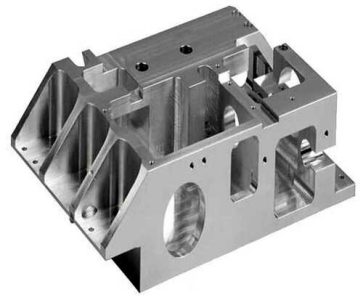

The optimization of CNC milling usage is based on the characteristics of milling parts. Through the technical and economic analysis and research of the CNC milling parts process, a scientific, reasonable and accurate milling parameter optimization mathematical model is established, and appropriate optimization algorithms are adopted.

The optimization of CNC milling usage is based on the characteristics of milling parts. Through the technical and economic analysis and research of the CNC milling parts process, a scientific, reasonable and accurate milling parameter optimization mathematical model is established, and appropriate optimization algorithms are adopted.

What is the amount of milling?

With the rapid development of modern manufacturing technology, there are more and more parts with various complex forming surfaces and high precision requirements. As one of the main processing methods of this kind of parts, CNC milling processing. The choice of cutting amount will have a greater impact on processing efficiency, tool durability, processing cost and processing quality.

Milling optimization model

Find a set of numerical control milling parameters that minimize the value of the objective function in the feasible area of milling parameters. Therefore, the key to the optimization of CNC milling parameters is to establish the numerical relationship between the design variables, the optimization goals, and the constraints, that is, to establish the optimization mathematical model.

In optimal design, the independent parameters that need to be optimized are called optimal design variables. The cutting parameters such as spindle speed, feed speed, milling thickness, cutting width in CNC milling are the factors that affect the realization of CNC milling goals, and are the basic control quantities in the CNC milling process. There is actually the best combination scheme between them. Therefore, in the mathematical model of numerical control milling parameters optimization, the spindle speed n, the feed speed vf, the amount of back tool ap, the cutting width ae, etc. are used. The cutting amount is a design variable.

Milling objective function

The objective function is a function of design variables and an index for comparing and selecting various design schemes. The objective function of numerical control milling parameter optimization should be consistent with the purpose of numerical control milling processing. The purpose of CNC machining is to maximize economic benefits, that is, through the best combination of cutting parameters, give full play to the cutting efficiency of machine tools and tools, and under the premise of ensuring the quality of processing, reduce processing costs as much as possible and increase productivity. Both processing cost and productivity can establish a functional relationship with the cutting amount. Therefore, taking processing cost and productivity as the objective function of numerical control milling consumption optimization is in line with the actual needs of production.

Constraints for milling

The choice of CNC milling amount is limited by technical conditions such as CNC machine tools, tools, workpieces and processing quality, and the range of cutting amounts available for selection is limited. Therefore, the constraint conditions for the optimization of numerical control milling parameters should be established based on these restrictions, so that the optimized results are in line with the actual production.

Multi-objective optimization background of cutting parameters

The optimal selection of metal cutting processing parameters is of great significance to ensure processing quality, increase productivity and economic benefits. It is also particularly important for CNC machine tools, especially machining centers. Due to the complexity and uncertainty of the machining process, many factories choose the cutting amount based on experience, but the actual results vary greatly from person to person. In order to control and ensure the quality of processing, give full play to the energy efficiency of CNC machine tools, so that the choice of cutting parameters is changed from empirical judgment to quantitative analysis. With the help of computer technology, the cutting parameters are optimized with simple and reliable optimization algorithms to meet the actual needs of cutting.

The price and labor cost of CNC machine tools are relatively high, and the proportion of tool wear costs is relatively low. Therefore, in most materials, high milling amount should be used as much as possible. According to this choice, it is possible to reduce the proportion of machine tool labor cost in the part manufacturing cost, which is a positive side. However, high cutting consumption will reduce the durability of the cutting tool, requiring frequent replacement or sharpening of the tool, thereby reducing productivity;

High cutting consumption is prone to waste products and reduces the reliability of machine tools.

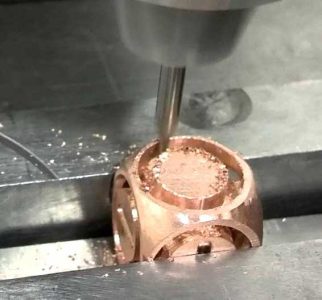

The amount of copper NC Milling

The amount of milling of stainless steel

The amount of high-speed milling characteristics

Characteristics of high-speed milling cutting parameters

High feed speed

High-speed milling cutting parameters have a very high feed rate. With the substantial increase in cutting speed:

Relative velocity between on the one hand, to speed up the chip and tool, tool - the contact between the chip temperature rises; A soft stagnant layer is formed on the bottom surface of the chips, which reduces the friction coefficient between the knife and the chips; On the other hand, as the temperature difference between the bottom and the top of the chip increases, the bottom of the chip heats up and expands, which increases the degree of curvature of the chip when it flows through the rake face. It can be seen that as the cutting speed increases, the additional deformation of the chips due to friction in the second deformation zone is reduced, and the tool-chip contact length is shortened due to severe chip bending, so the degree of chip shear deformation decreases. As a result, the shear angle is increased, the chip deformation is reduced, and favorable conditions are created for the increase of the feed motion speed.

High milling speed

High-speed machining cutting consumption has a very high cutting speed, which is generally 5-10 times higher than ordinary cutting speed, and the spindle speed can reach 10000-100000r/min.

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe