Product Categories

Product Tags

3 axis, 5 axis CNC milling precision machining

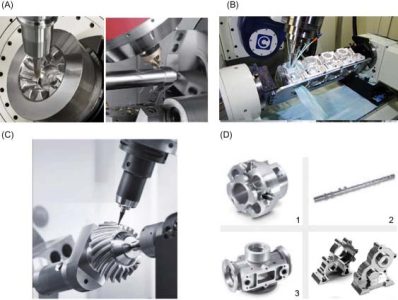

The CNC milling machine can process complex shapes of rotating bodies. In milling, the blank is first fixed, and a high-speed rotating milling cutter is used to move the blank on the blank to mill out the required shape and features. Traditional milling is mostly used to mill simple shape features such as contours and grooves. The CNC milling machine can process complex shapes and features. The milling and boring machining center can perform three-axis or multi-axis milling and boring processing for processing: molds, inspection tools, molds, thin-walled complex curved surfaces, artificial prostheses, impeller blades, etc. When choosing CNC milling parts, the advantages and key functions of CNC milling machines should be fully utilized.

CNC milling is a high-tech processing method for precision parts, which can be processed into parts with complex structures combined with square and circular shapes.

The CNC milling machine can process complex shapes of rotating bodies. In milling, the blank is first fixed, and a high-speed rotating milling cutter is used to move the blank on the blank to mill out the required shape and features. Traditional milling is mostly used to mill simple shape features such as contours and grooves. The CNC milling machine can process complex shapes and features. The milling and boring machining center can perform three-axis or multi-axis milling and boring processing for processing: molds, inspection tools, molds, thin-walled complex curved surfaces, artificial prostheses, impeller blades, etc. When choosing CNC milling parts, the advantages and key functions of CNC milling machines should be fully utilized.

Various types of materials can be processed, such as 316, 304 stainless steel, carbon steel, alloy steel, alloy aluminum, zinc alloy, titanium alloy, copper, iron, acrylic, Teflon, POM rods and other metal and plastic raw materials.

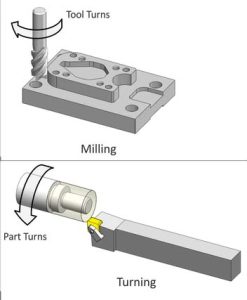

The difference between turning and milling

Turning and milling is a common metal cold working method. The difference from turning is that in milling, the tool rotates at a high speed under the drive of the spindle, while the workpiece is relatively stationary.

The difference between turning and milling:

Turning is used to machine rotating parts. The parts are clamped on the main shaft of the machine tool through the three gripping chucks and rotate at high speed. Then use a turning tool to move the tool according to the generatrix of the revolving body to cut out the shape of the product. The lathe can also process the inner hole, thread, biting, etc. The latter two are low-speed processing.

Milling process

(1) Milling the curve contour on the workpiece, straight line, arc, thread or spiral curve, especially the non-circular curve and list curve given by mathematical expression.

(2) Milling the spatial curve or surface of the given mathematical model.

(3) Although the milling shape is simple, the product has a wide range of sizes and positions where internal inspection is difficult.

(4) The milling machine can process cavities, box parts, etc. that are difficult to observe, control and detect when processed by ordinary machine tools.

(5) Holes or planes with strict size requirements.

(6) All simple surfaces or shapes can be processed by milling in one clamping.

(7) General processing that can effectively improve productivity and reduce labor intensity by using CNC milling processing.

The main processing objects suitable for CNC milling include the following categories: plane contour parts, variable bevel parts, spatial curved surface contour parts, holes and threads, etc.

Operation points of milling

- The milling machine operator should wear tight-fitting work clothes with cuffs tied tightly; Female operators must wear protective caps; Wear protective glasses when high-speed milling; Wear a mask when milling iron castings; It is strictly forbidden to wear gloves during operation to prevent your hands from being caught between the rotating tool and the workpiece.

2. Before operation, check whether the parts and safety devices of the milling machine are safe and reliable;

Check whether the electrical parts of the equipment are safe and reliable.

3. When loading and unloading workpieces, the workbench should be returned to a safe position. When using a wrench to tighten the workpiece, the direction of force should avoid the milling cutter to prevent the wrench from hitting the tool or fixture when it slips.

4. When assembling and disassembling the milling cutter, use a special pad to pad it. Do not hold the milling cutter directly with your hands.

5. When milling irregular workpieces and using vise, dividing head and special fixture to hold the workpiece. The center of gravity of irregular workpieces, vices, indexing heads, special fixtures, etc. should be placed in the middle of the workbench as much as possible to avoid uneven force and deformation of the workbench.

6. During fast or automatic feed milling, do not move the worktable to the two extremes to avoid squeezing the screw rod.

7. When the milling machine is running, it is not allowed to adjust, measure the workpiece and change the lubrication method to prevent the hand from touching the tool and hurting the fingers.

8. Before the rotation of the milling cutter is completely stopped, it is not allowed to brake by hand.

9. Do not remove the chips by hand or blow with your mouth during milling to prevent the chips from damaging the skin and eyes.

10. During motorized rapid feed, the handle wheel clutch should be opened to prevent the hand wheel from rotating quickly and hurting people.

11. When the workbench is reversing, the reversing handle must be stopped at the middle position first, and then reversing. Direct reversal is not allowed.

12. When milling keyway shafts or milling thin workpieces, prevent the surface of the indexing head or worktable from being milled.

13. When milling a plane, a cutter head with more than four milling cutter heads must be used, and an appropriate cutting amount must be selected to prevent the machine tool from vibration during milling.

14. After work, stop the workbench at the middle position, and drop the lifting platform to the lowest position.

15. For CNC vertical milling machines, pre-select items such as work procedures, spindle speed, tool feed, tool motion trajectory, and continuous offsides according to technological requirements before work. Put the electric knob in the "adjustment" position for trial run. After confirming that there is no problem, put the electric knob in the automatic or semi-automatic position to work.

5 axis Milling aluminum Cavity

difference between turning and milling

Milling process of curve contour, straight line and arc

5-axis milling housing curved contour

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe