Gemeenschappelijke oppervlaktebehandeling van verwerkte prototypes: slijpen, polijsten, galvaniseren, oxidatie, passivatie, zwart worden, fosfateren, enz.

In het gehele proces van prototypeverwerking, na het selecteren van de juiste verwerkingsmethode (CNC-bewerking of 3D-printen), de meeste prototypes vereisen een oppervlaktebehandeling. Het doel van oppervlaktebehandeling is om te voldoen aan de corrosieweerstand van het product, slijtvastheid, decoratie of andere bijzondere functionele eisen. Er zijn tientallen oppervlaktebehandelingsprocessen voor prototypeverwerking. Volgende, we zullen de gebruikelijke oppervlaktebehandelingsprocessen voor prototypeverwerking introduceren.

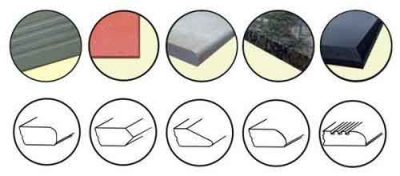

Surface treatment process of prototype

CNC prototype surface finishing

1. Sanding :

Sanding is one of the most common surface treatment techniques. Over het algemeen, rough objects (such as sandpaper with higher hardness particles) are used to change the physical properties of the material surface through friction. Remove burrs, machining lines, bonding marks and other defects on the surface of the workpiece, thereby improving the flatness of the workpiece, reducing the roughness, and making the surface of the workpiece smooth and fine.

2. Polishing:

Polishing uses flexible polishing tools and abrasive particles or other polishing media to modify the surface of the workpiece on the basis of Sanding. Polishing cannot improve the dimensional accuracy or geometric accuracy of the workpiece, but aims to obtain a smooth surface or mirror gloss, and sometimes it is also used to eliminate gloss (matting). The surface roughness of the workpiece after the polishing process can generally reach Ra 0.63 ~ 0.01 micron.

Rapid prototyping polishing

Snelle prototype-platering

3. Galvaniseren:

Electroplating is the use of electrodes to attach metal to the surface of an object, and its purpose is to change the characteristics or dimensions of the surface of the object. Electroplating is generally divided into wet electroplating and dry electroplating. Wet method is usually called water plating; Dry electroplating is commonly referred to as vacuum plating.

Water electroplating is to replace and adhere the metal ions of the coating to the surface of the workpiece by the electrode method; Vacuum plating uses high voltage and high current to make the coated metal instantly vaporize into ions in a vacuum environment and then vaporize to the surface of the plating part. The water plating has good adhesion, no other treatment is needed in the later stage; The adhesion of vacuum plating is poor, and PU or UV is generally required on the surface. PC cannot be electroplated, and composite parts cannot be water-plated, only vacuum plating. The color of water plating is relatively monotonous, and common water plating includes chrome, nickel, and gold. The vacuum plating can solve the seven-color problem. Before water plating, the surface effect of the workpiece must be polished to 1500-2000 sandpaper, and then polished before water plating can be carried out. Daarom, water-plated workpieces are generally very expensive; The effect of vacuum plating and polishing can be slightly worse than 800-1000 sandpaper, so vacuum plating is relatively cheap.

4. Oxidation:

Metal oxidation treatment is: the metal surface reacts with oxygen or oxidant to form a protective oxide film to prevent metal corrosion. Oxidation is divided into chemical oxidation and electrochemical oxidation (ie anodic oxidation).

(1) The oxide film produced by chemical oxidation is thin, about 0.3-4um in thickness, porous, and has good adsorption capacity. It is soft and not wear-resistant, and has good electrical conductivity. It is suitable for occasions with shielding requirements and can be painted in various colors. It has good adsorption capacity and can oxidize various colors. Painting on the surface can effectively improve the corrosion resistance and decoration of aluminum products.

(2) The oxide film produced by anodic oxidation is relatively thick, and the thickness is generally 5-20um. The thickness of the hard anodized film can reach 60-2500um, with high hardness, good wear resistance, good chemical stability, good corrosion resistance and good adsorption capacity. It has good insulation performance, strong heat insulation and heat resistance, and can be painted in various colors.

Aluminum and aluminum alloys undergo chemical oxidation treatment, especially after anodic oxidation treatment, the oxide film formed on the surface has good protection and decoration characteristics. Daarom, it is widely used in aviation, electrical, electronic, mechanical manufacturing and light industry.

Oxygen oxidation treatment for rapid prototyping

Surface treatment process-oxidation

5. Passivation:

Under certain conditions, when the potential of the metal shifts to the positive direction due to the external anode current or the local anode current, the surface state of the metal that was originally active and dissolved will undergo a sudden change. The dissolution rate of the metal drops rapidly. This sudden change of the surface state is called passivation.

Passivation can improve the passivation performance of metal materials, promote the passivation of metal materials in the use environment, and improve the mechanical strength of the metal. It is one of the most effective ways of corrosion control, which enhances the adhesion of metal and coating film.

6. Blackening:

Blackened surface treatment is also called bluing. There are two commonly used methods for blackening treatment: the traditional alkaline heating blackening and the late normal temperature blackening.

The blackened protective film is black, which improves the corrosion resistance and mechanical strength of the metal surface, and can also be used as a good bottom layer for coatings. (Stainless steel cannot be blackened, iron has the best blackening effect)

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe