In the early 1960s, due to the gyroscopes used in aerospace, the drums and disks used in computers, and the polygonal prism parts used in optical scanning. Large-diameter non-circular curved mirror parts for high-power laser nuclear fusion devices, as well as stereoscopic mirrors for various complex shapes of infrared light, 등. All kinds of mirrors and multi-faceted prism parts require extremely high precision, and they are processed by grinding, 연마, polishing and other methods. Not only the processing cost is high, but it is also difficult to meet the requirements of accuracy and surface roughness. 이를 위해, the research and development of the use of high-precision, high-rigidity machine tools and diamond tools for cutting and milling processing methods.

SPDT 기술로 시작된 초정밀 절단, 에어베어링 스핀들에 의해 지지되는, 공압 슬라이드, 높은 강성, 고정밀 도구, 피드백 제어, 나노 수준의 표면 거칠기를 얻기 위한 환경 온도 제어. 다이아몬드 절단기가 주로 사용됩니다., 구리 평면 및 비구면 광학 요소 가공에 널리 사용됩니다., 플렉시글라스, 플라스틱 제품 (카메라 플라스틱 렌즈와 같은, 콘택트렌즈 렌즈, 등.), 세라믹 및 복합 재료.

Ultra-precision cutting and milling technology is an advanced manufacturing technology developed to meet the needs of modern high-tech. Precision CNC machining is an indispensable key technology in the development of high-tech cutting-edge products, an important symbol of a country’s manufacturing level, and one of the indispensable key technologies for equipment modernization. Precision parts have very broad application prospects in military and civilian industries.

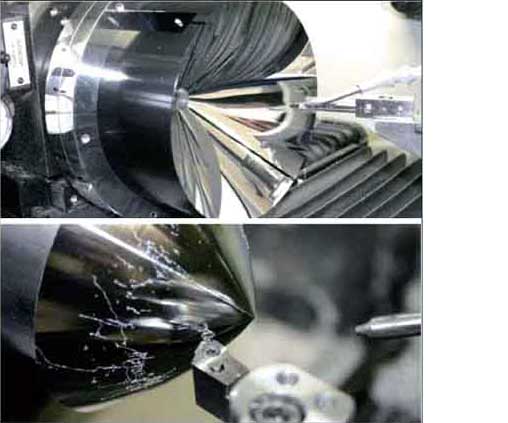

Schematic diagram of the finished optical component processed by SPDT

The parts of various shapes shown in the picture are deoxidized copper or aluminum alloy materials

초정밀 밀링 기술

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe