하는 것은 비윤리적이다 “실제 CNC 공작 기계 없이 정밀도에 대해 이야기하다”. 라고 하면 “5축 CNC 공작 기계의 정밀도는 3축 CNC 공작 기계의 정밀도보다 확실히 높습니다.”, 그럼 그건 완전히 종이 위에 있는 거야. 고급 3축 공작기계는 일반 5축 공작기계보다 가공 정확도 지수가 더 높다는 것은 전적으로 가능합니다..

3축 공작 기계에는 3개의 선형 축이 포함되어 있습니다., 엑스, 와이, 그리고 Z, and its structure is relatively simple. During the processing of the 3-axis machining center, the direction of the tool axis will not change, the motion mode is also limited, and the programming is relatively simple.

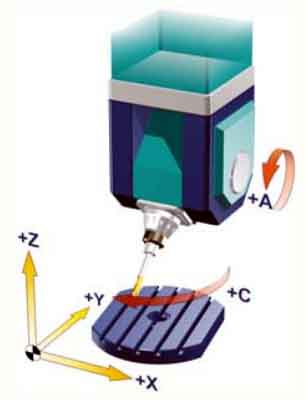

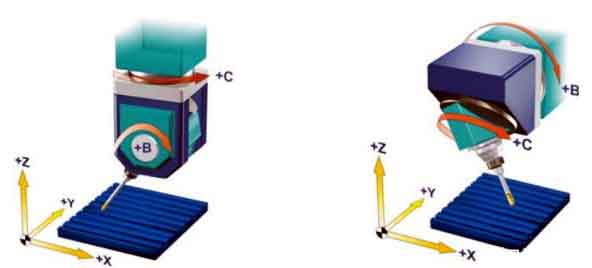

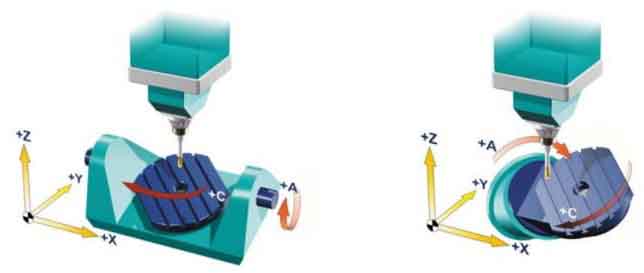

On the surface, a 5-axis machine tool has two more rotation axes than a three-axis machine tool. 그건, in addition to the three linear axes of X, 와이, 그리고 Z, a 5-axis machine tool also includes two of the A, 비, and C rotation axes around the three linear axes of X, 와이, and Z respectively. Mainly include the following combinations:

5-axis single turntable type – 5-axis single pendulum head type

5-축 회전 헤드 유형 (왼쪽) 5축 틸트 스위블 헤드 타입 (오른쪽)

5-axis swivel type (왼쪽) and 5-axis tilt swivel type (오른쪽)

그만큼 “5-axis tilting head” mentioned in the figure means that there is a rotating axis that is not perpendicular to the three linear axes, which is relatively rare. Its motion relationship is more complicated, but its structure is relatively compact, and its dynamic and static rigidity is better.

The difference between three-axis and five-axis is mainly reflected in the processing capacity. A five-axis machine tool can do the work of a three-axis machine tool, but the three-axis machine cannot complete the work of a five-axis machine tool. This shows that the existence of two rotating axes gives the five-axis machine tool stronger processing capabilities.

The advantages of the five-axis are mainly reflected in the following points:

1. Reduce the number of clamping. Due to the existence of two rotating shafts of the five-axis machine tool, the tool can approach the workpiece from any direction, and one clamping can realize the processing of all surfaces except the mounting surface. “Reduce the number of clamping times” can be described as two goals for the pursuit of high-efficiency and high-precision machining. 한편으로는, reducing the number of clamping times can save time, reduce the labor intensity of workers, and improve processing efficiency;

반면에, it is possible to minimize possible errors caused by clamping and ensure processing accuracy.

2. Maintain the best cutting condition of the tool. Due to the use of a five-axis machine tool, the tool can approach the workpiece from any direction, so that the tool can cut the workpiece at the most appropriate angle. It can also improve processing efficiency and processing quality.

3. Effectively avoid interference between tools. Also because of the existence of two rotating axes of a five-axis machine tool, the tool can approach the workpiece from any direction, making the processing path flexible and changeable. Can effectively avoid the interference problem in the processing process.

4. Shorten the development cycle. This is also the effect that is naturally achieved after the quality and efficiency are improved.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe