제품 카테고리

- CNC 밀링 서비스 31

- CNC 스탬핑 서비스 0

- CNC 판금 0

- 신속한 프로토 타입 12

- 스탬핑 다이 0

- 티타늄 합금 부품 4

- 스테인레스 스틸 부품 5

- 알루미늄 밀링 부품 14

- CNC 터닝 서비스 16

10 CNC 가공 프로토타입용 재료

3D 프린팅과 비교, CNC 프로토타입의 가장 큰 장점은 소재의 풍부함과 실용성입니다.. 프로토타입의 주요 목적은 제품 디자인의 타당성을 검증하는 것입니다., 그래서 프로토타입의 재료도 매우 특별합니다.. 회사마다 제품이 달라요, 제작해야 하는 프로토타입 모델도 다릅니다.. 그러므로, 생산 재료도 다를 수 있습니다, 그러나 주요 가공 재료는 다음과 같습니다:

3D 프린팅과 비교, CNC 프로토타입의 가장 큰 장점은 소재의 풍부함과 실용성입니다.. 프로토타입의 주요 목적은 제품 디자인의 타당성을 검증하는 것입니다., 그래서 프로토타입의 재료도 매우 특별합니다.. 회사마다 제품이 달라요, 제작해야 하는 프로토타입 모델도 다릅니다.. 그러므로, 생산 재료도 다를 수 있습니다, 그러나 주요 가공 재료는 다음과 같습니다:

2. PC: Material with good strength, toughness and transparency, suitable for the production of Lens and fine structure parts. 게다가, glass fiber is added to improve the steel and heat resistance of the board, which can be used to make parts that need to maintain high rigidity in a high temperature environment. PC also has UL94-V0 fire rating;

3. PMMA: Namely acrylic, or plexiglass. It is a good transparent part, the material with the best transparency can be made with surface treatment such as dyeing, 전기 도금, spraying, and screen printing. The welding strength is acceptable, but fragility is its weak point, and it is not suitable for use in vulnerable places such as hooks;

4. PP: Translucent material, good impact resistance, excellent flexibility, can be applied to products with strict impact resistance conditions. 와 같은: automotive supplies, half-folding packaging boxes, 등.

5. PA66+GF30: PA66+GF30 is not a model, it is a general code for PA66 plastic materials with 30% glass fiber. 고강도, special thermal stability, hydrolysis resistance, suitable for auto parts, mechanical parts, 등. It is used as a shield for mechanical parts that require high rigidity and dimensional stability. Red phosphorus flame retardant has long-term stability and excellent mechanical processing performance;

6. 포엠: It is called polymethine raw material in Chinese, also known as polyoxymethine raw material. It is often called Saigang in the prototype industry. The regular molecular structure and crystallinity make its physical and mechanical properties very excellent, and it is called metal plastic. In the prototype model, it is suitable for high-strength workpieces, such as gears, 샤프트, brackets, 등.;

7. 테프론: The chemical name is polytetrafluoroethylene (PTFE for short), which is generally called "non-stick coating" 또는 "easy to clean material". This material is resistant to acids, alkalis, and various organic solvents, and is almost insoluble in all solvents. 동시에, PTFE has the characteristics of high temperature resistance, and its friction coefficient is very low, so it can be used for lubrication and become an ideal coating for easy cleaning of the inner layer of water pipes;

8. Aluminum alloy: Aluminum alloy is the most widely used non-ferrous metal structural material in prototype models, and has been widely used in aviation, 항공우주, 자동차, 의료, and ship prototype models. 현재, aluminum alloy is the most used alloy in prototypes. The advantages are easy processing and forming, good rigidity, and rich anode coloring;

9. Magnesium alloy: light weight and good strength, it is a favorite material for consumer 3C. The disadvantage is that magnesium is a flammable metal, and environmental control is very important during machining. The manufacturing process of magnesium alloy model is highly dangerous, and there are many machining processes after die-casting during production, which is a high-cost application material;

10. 놋쇠: Brass is an alloy composed of copper and zinc. Brass composed of copper and zinc is called ordinary brass. If it is a variety of alloys composed of two or more elements, it is called special brass. Brass has strong wear resistance. Brass is often used in prototype models to replace materials that are difficult to engrave and mill, such as stainless steel. After polishing and electroplating, the surface effect and feel are very close to stainless steel.

CNC machined ABS prototype

CNC machining PC prototype

CNC machining PP rapid prototype

Aluminum alloy rapid prototyping

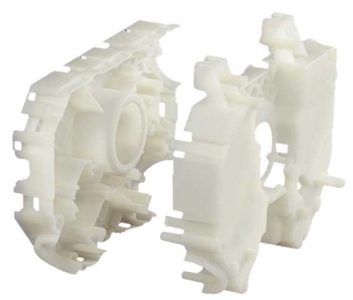

CNC machining POM rapid prototyping

문의하기

이메일을 기다리는 중, 이내에 답변해 드리겠습니다. 12 필요한 귀중한 정보를 몇 시간 동안.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe