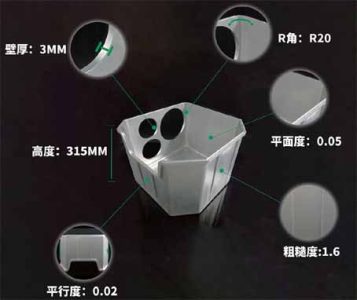

The aluminum alloy cavity is used in aerospace products. Milling parameters (difficulty): product height 315mm, internal R20, 평탄 0.05, 병행 0.02, roughness 1.6.

The aluminum cavity is a shell of an aerospace component customized for an aerospace manufacturing company. The aluminum cavity is a high-precision and difficult CNC milling cavity. The processing depth is as high as 315mm, and the accuracy requirements for parallelism and flatness are very high. Since I signed a non-disclosure agreement with the client, the details will not be described again.

상품명: Aluminum cavity used in military industry

가공방법: CNC milling of aluminum alloy cavity

재료: 알루미늄 합금

표면 처리: 세련, 디버링, 산화

처리주기: 3-7 근무일 기준 7일

테스트 표준: 3고객이 제공한 D 도면

데이터 형식: STP/IGS/X.T/PRO

제품 특징: 부드러운 표면, 고광택, 훌륭한 솜씨

Difficulties of CNC milling aluminum cavity

CNC machining of aluminum cavity used in aviation

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe