범주: CNC machining of aluminum alloy heat sink

상품명: Aluminum alloy heat sink

가공방법: aluminum alloy cnc processing

재료: 알루미늄 합금, 알류미늄, 구리

표면 처리: 세련, 디버링, 그림

Machining cycle: 3-7 근무일 기준 7일

테스트 표준: 3고객이 제공한 D 도면

데이터 형식: STP/IGS/X.T/PRO

제품 특징: 부드러운 표면, spray paint, 고광택, 훌륭한 솜씨, clear lines

방열판 쉘 제조업체

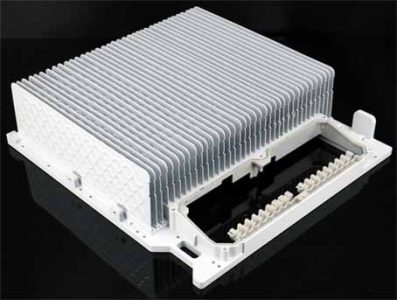

법 집행 기록관의 방열판 하우징. 이 기술은 법 집행 기관의 실제 요구 사항을 충족하도록 설계 및 개발되었습니다.. 경찰 개인 법 집행 기록 장치를 위한 효율적이고 실용적인 방열 솔루션입니다.. 경찰 모바일 단말기에 적합합니다., 보안 장비 모바일 단말기, 모니터링 장비 모바일 단말기, 등., 다양한 용도로. 현재 경찰 법 집행 기록의 대부분은 장기간 근무 조건에서 발열 문제를 극복할 수 없습니다.. 법 집행 기록의 전반적인 성능을 향상시키기 위해, 실제 요구 사항을 활용한 경험의 의미에서 법 집행 기록, 현재 널리 퍼진 시장 집행 레코더 열풍에 대한 솔루션, 가난한 경험 문제의식;

Further improve the performance of the whole machine, increase the service life of the law enforcement recorder, change the traditional use experience before, and improve the work efficiency of law enforcement officers in the duty.

CNC milling of aluminum heat sink shell

The new technology provides a heat sink and housing for law enforcement recorders.

The utility model is realized through the following measures:

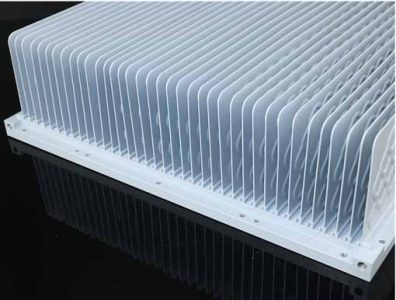

A heat sink for a law enforcement recorder, which is characterized in that it comprises: The square plate body and the heat dissipation end portion vertically arranged on one side of the square plate body, the other three sides of the square plate body are uniformly provided with a plurality of notches, and the outer surface of the heat dissipation end portion is provided with a plurality of heat dissipation protrusions. The heat dissipation protrusion has the function of increasing the contact area with the outside air and improving the heat dissipation effect.

그 중, the heat sink is an integrally formed die casting; the material of the heat sink is aluminum-magnesium alloy.

A fixing hole is arranged on the heat sink, and the heat sink is fixed on the housing of the law enforcement recorder by screws or rivets passing through the fixing holes.

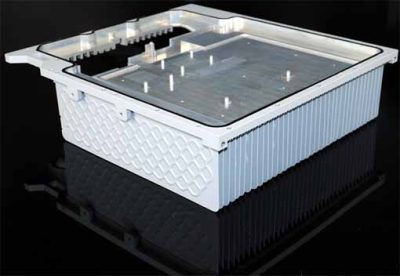

In order to better achieve the above-mentioned purpose of the invention, the present invention also provides a housing for a law enforcement recorder, which includes a frame-shaped housing, a display screen connected to the housing, and a back cover. Wherein, it also includes a heat sink arranged at the lower end of the casing;

A socket is opened on the side wall of the lower end of the housing, the square body of the heat sink is located in the housing, and the outer surface of the heat sink end is exposed to the air; Both ends of the heat dissipation end are provided with fixing holes, the lower end of the housing is provided with mounting holes, and the heat sink is fixed on the housing by screws or rivets passing through the mounting holes and the fixing holes.

Wherein, the outer surface of the side wall of the lower end of the casing is provided with a plurality of positioning protrusions. The inner surface of the heat dissipation end portion is provided with a plurality of positioning sockets that cooperate with the positioning protrusions.

The heat sink is an integrally formed die casting.

Supplier of aluminum heat sink housing

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe