5-베이스 부품의 축 가공

고성능 5축 CNC 밀링 머시닝센터, CNC 시스템에는 공간 좌표계 회전 및 경사 공구 보정 기능이 있습니다., 경사면 가공과 높은 가공 정밀도가 필요한 일부 부품의 가공 가능성을 제공합니다.. 경사면에서 가공할 때, 공간에 따라 좌표계가 변하기 때문에 가공 프로그램을 컴파일하기가 어렵습니다.. 프로그래밍을 위해서는 기존의 프로그래밍 사고 방식을 돌파해야 합니다., 프로그램의 특수 처리. This article discusses this issue in conjunction with the actual processing of model products.

Such parts are often encountered in the production process of products, and they need to be punched, bored, and milled on the inclined surface. Or it needs to be processed on several inclined surfaces with different directions and different slopes in the same clamping, 각 경사면에는 더 높은 기하학적 공차 요구 사항이 있습니다.. The conventional method of processing such parts is to pull the head of the bed, 작업대를 회전시키거나 모듈식 고정 장치를 사용하십시오.. 가공 방향이나 가공 위치가 다른 경우, 두 번째 클램핑 및 재정렬이 필요합니다., 그리고 처리과정이 너무 까다로워요. 클램핑 위치 및 공작 기계 자체의 제한으로 인해, 부품의 가공 정확도는 보장할 수 없습니다.. 예를 들어, in the T×× table body processing, there are many holes on the inclined surface, 특수한 모양의 표면은 고정하기가 쉽지 않습니다., the positioning reference is not good, and the error accumulation caused by multiple clamping, sometimes the hole margin error exceeds 1mm.

In order to solve the processing problem of this kind of parts, 공정 방법에 대한 지속적인 탐구와 지속적인 개선을 통해, combined with the factory’s existing machine tools, a five-axis CNC milling machining center was selected to solve this problem. 선택한 공작기계는 5축 연동입니다. In addition to 3 선형 축, 또한 두 개의 회전축이 있습니다. (C축: -360°~360°) 그리고 스윙 헤드 (B축: 0°~110°). The control system used is FANUC160i, which has the functions of space coordinate system rotation and inclined tool compensation.

From the perspective of realizing bevel processing, multiple bevels in different directions and different angles can be punched, 지루한, tapped, milled and other processes can be completed after one clamping. Reduce the number of clamping times, reduce labor intensity, shorten the production cycle of the product, 그리고 더 중요한 것은, improve the processing accuracy of the parts and ensure the consistency of product quality.

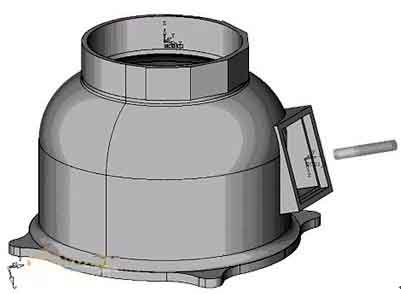

Take the processing of a certain base part as an example. The parts are shown below: To process this base, 공작 기계가 XZ 및 YZ 평면에서 2축 연결 보간과 스핀들 헤드 스윙 동작을 완료해야 함을 알 수 있습니다.. 공구를 가공면에 수직으로 만들기 때문에, 스핀들은 헤드 스윙 동작을 완료해야 합니다.. Having a rotating head involves a series of multi-axis machining issues such as pendulum length. 그러므로, it is necessary to use multi-axis programming means to complete. Programming and machine tool debugging are difficult, which puts higher demands on programmers and machine operators. 실제 응용 분야, 공작 기계의 안전 보장과 같은 요소를 고려합니다., it is necessary to simulate the processing process and perform multiple air cuts to ensure that the program is correct before formal processing can be performed. 게다가, 다축 프로그램 알고리즘은 상당히 복잡합니다., 진자 길이와 같은 요인의 영향을 고려해야 합니다.. 특정 공작 기계에는 특정 후처리가 있어야 합니다., but the post-processing is often due to the difference in algorithms and control positions, as well as the influence of calculation stability. 소프트웨어 후처리를 통해 얻은 프로그램은 제어 정확도 측면에서 부품 도면의 정확도 요구 사항을 충족하기 어려운 경우가 많습니다..

The analysis shows that the direct cause of the increase in programming difficulty is the appearance of the inclined plane. 그러므로, 가공 평면이 경사면과 일치하도록 만들 수 있는 경우, 그러면 이런 종류의 문제는 2축 반처리 프로그래밍 문제로 변환됩니다., 프로그래밍 난이도가 크게 줄어들 것입니다.. 그러므로, it is conceivable to use the coordinate system conversion function of the machine tool (G68 지령) 가공면을 경사면과 일치시키려면. The second tool length compensation command (G432) is used to add the tool length in the vertical direction of the inclined plane. 위와 같은 처리를 한 후, 베벨 가공의 문제를 평면 가공으로 변환하여 해결, thus the programming difficulty is greatly reduced. 여러 개의 경사면을 동시에 처리해야 하는 경우, C축을 C0으로 회전시키기만 하면 됩니다. (작업대의 영 위치, 영점 위치의 방향은 스핀들의 스윙 방향과 동일합니다.), 그런 다음 좌표계를 회전하고 공구 길이를 늘려 가공을 실현합니다.. 가공형태가 비교적 단순한 경우, programming can be done manually. This makes it possible to realize the machining of multiple inclined surfaces, multiple positions, CNC 공작 기계의 단일 클램핑으로 여러 번의 공구 교환이 가능합니다..

The program structure is as follows:

%

N0100O0008 (프로그램 이름)

N0102M6T1; (도구 변경)

N0104G0G90G56X400Y200Z260B0C0; (Move to the reference point)

N0106G432X200Z150H1Bω; (add the knife length in the direction perpendicular to the inclined plane)

N0108M3S3000; (Spindle forward rotation)

N0110M8; (open cutting fluid)

N0112G68X188Y0Z60I0J1K0Rω; (Coordinate system conversion, ω is the angle of rotation of the main shaft from zero to perpendicular to the inclined plane)

……

N0200G69; (cancel coordinate system rotation)

N0202G492X200Z300; (Slope tool compensation canceled, move to a safe position)

N0204M9; (cutting fluid off)

N0206Cα; (C axis rotation, α is the minimum angle between the vertical line of the nth inclined plane to be processed and the C0 position)

N0208G0G90G56X400Y200Z260B0C0; (Move to the reference point)

N0210G432X200Z150H1Bωn; (add the knife length in the direction perpendicular to the inclined plane)

N0212G68X188Y0Z60I0J1K0Rωn; (Coordinate system conversion, ωn is the angle of rotation when the main shaft turns from zero to perpendicular to the slope)

…

N0200G69; (cancel coordinate system rotation)

N0202G492X200Z300; (Slope tool compensation canceled, move to a safe position)

N0204M9; (cutting fluid off)

N0204M30; (program ends, return to program head)

Although the bevel machining has been achieved in the above discussion, it is limited to drilling, 지루한, 태핑, and milling on the bevel. The simple shapes composed of straight lines and arcs are limited to manual programming. If the milling shape is more complicated. Such as milling equation curves, three-dimensional curved surfaces, and lettering on an inclined plane, how to program it?

Even when these similar shapes are processed on a flat surface, manual programming is not possible, and it can only be completed by CAM software. Through careful study of machine tools and CAM software, a set of software programming combined with manual programming was found to be an effective way to complete the processing and programming of such parts.

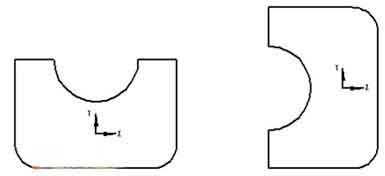

The analysis shows that in ordinary three-axis milling programming, the direction of the tool axis is always perpendicular to the XOY plane. But when the spindle deviates from the original vertical direction and the tool plane is inclined, how can the program generated on the XOY plane run correctly on the inclined plane? The analysis shows that although the coordinate system has been rotated, if the relative position of the figure (a) in the original coordinate system and the shape to be processed on the inclined plane (b) and the relative position in the new coordinate system are kept consistent on the XOY plane . Then the program generated on the XOY plane can be directly applied to bevel machining.

According to the influence of the swing head movement of the machine tool on the graphics position, the analysis shows that when drawing on the XOY plane, the graphics should be rotated 90° counterclockwise with the programming origin as the rotation center (the rotation angle should be determined according to the specific conditions of the machine tool). 이런 식으로, the graphic position in the CAM software is kept consistent with the actual machining position. By adding and modifying the program head and program end, 그건, adding coordinate system conversion and inclined tool compensation, software programming and manual programming are combined. This realizes the machining of arbitrary complex shapes such as milling equation curves, three-dimensional curved surfaces, and lettering on the inclined surface.

5-axis milling equation curve on inclined plane, three-dimensional surface

Through the actual machining verification, it is confirmed that the method is within the allowable range of the machine function and stroke, and the programming of this method can realize the machining programming of any complicated shape on any inclined plane.

The following figure shows an example of processing a three-dimensional curved surface on a 52° inclined plane:

Machining three-dimensional curved surface

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe