In the early 1960s, due to the gyroscopes used in aerospace, the drums and disks used in computers, and the polygonal prism parts used in optical scanning. Large-diameter non-circular curved mirror parts for high-power laser nuclear fusion devices, as well as stereoscopic mirrors for various complex shapes of infrared light, 等. All kinds of mirrors and multi-faceted prism parts require extremely high precision, and they are processed by grinding, 研削, polishing and other methods. Not only the processing cost is high, but it is also difficult to meet the requirements of accuracy and surface roughness. この目的を達成するために, the research and development of the use of high-precision, high-rigidity machine tools and diamond tools for cutting and milling processing methods.

SPDT技術で始まる超精密切削加工, エアベアリングスピンドルによってサポートされています, 空気圧スライド, 高剛性, 高精度工具, フィードバック制御, ナノレベルの表面粗さを実現する環境温度制御. ダイヤモンドカッターが主に使用されます, 銅製の平面および非球面光学素子の加工に広く使用されています。, プレキシガラス, プラスチック製品 (カメラのプラスチックレンズなど, コンタクトレンズレンズ, 等), セラミックスと複合材料.

Ultra-precision cutting and milling technology is an advanced manufacturing technology developed to meet the needs of modern high-tech. Precision CNC machining is an indispensable key technology in the development of high-tech cutting-edge products, an important symbol of a country’s manufacturing level, and one of the indispensable key technologies for equipment modernization. Precision parts have very broad application prospects in military and civilian industries.

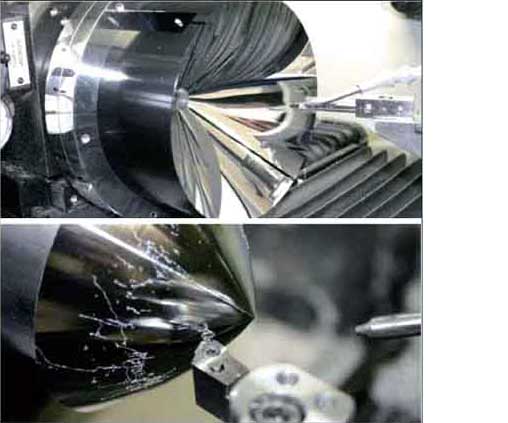

Schematic diagram of the finished optical component processed by SPDT

The parts of various shapes shown in the picture are deoxidized copper or aluminum alloy materials

超精密フライス加工技術

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe