片刃ボーリング工具ボーリングには次のような特徴があります。:

(1) ボーリングの適応力が強い. 穴あけ加工に基づいてボーリングを実行できます, 鋳造および鍛造穴. 達成可能な広範囲の寸法公差レベルと表面粗さ値;

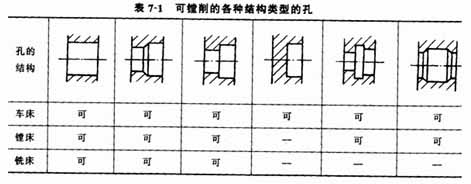

Except for the small and deep holes, almost all holes of various diameters and structures can be bored, as shown in Table 7-1.

(2) Boring can effectively correct the position error of the original hole. しかし, because the diameter of the boring bar is limited by the hole diameter, its rigidity is generally poor, and it is easy to bend and vibrate. したがって, the control of boring quality (especially for elongated holes) is not as convenient as reaming.

(3) The productivity of boring is low. Because boring requires multiple passes with a smaller depth of cut and feed to reduce the bending deformation of the tool bar. 加えて, boring on boring machines and milling machines requires adjusting the radial position of the boring tool on the tool bar, so the operation is complicated and time-consuming.

(4) Boring is widely used in the hole processing of various parts in single-piece and small-batch production. 量産中, boring the bearing holes of the bracket and box body requires a boring die.

Features of boring

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe