(1) NC加工軌道方式

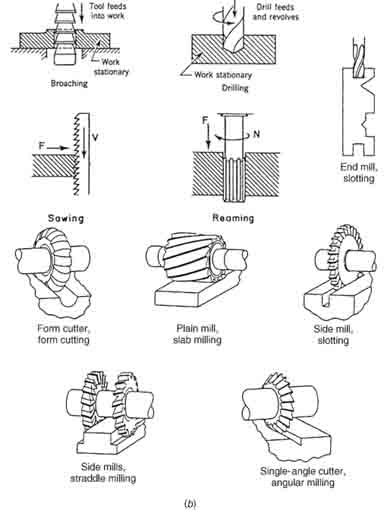

工具先端の移動軌跡を利用して加工面の形状を形成する加工方法です。. 普通旋削, フライス加工, 平削りと研削はすべて工具先端パス法に属します. この方法で得られる形状精度は主に成形動作の精度に依存します。.

(2) CNCマシニングの成形方法

成形工具の形状を使用して工作機械の特定の成形動作を置き換え、加工面の形状を取得します。. 旋削加工など, フライス加工, 研削, 等. 成形法で得られる形状精度は主に工具刃先の形状に依存します。.

(3) スポーツ開発メソッド

Using the tool and the workpiece to generate the include surface formed by the movement to obtain the shape of the machined surface. Such as gear hobbing, gear shaping, gear grinding, and knurling splines are all kinematic generation methods. The shape accuracy obtained by this method mainly depends on the shape accuracy of the cutting edge and the accuracy of the generated motion.

Tool tip path method for turning, フライス加工, planing and grinding

3. Method of obtaining position accuracy

In machining, the accuracy of the position of the processed surface on other surfaces is mainly determined by the clamping of the workpiece.

(1) Directly find the correct clamping

This method is to use a dial indicator, a marking plate or visual inspection to directly locate the workpiece on the machine tool.

(2) Mark the line to find the formal clamping

This method first draws the center line, the symmetry line and the processing line of each surface to be processed on the blank according to the part drawing. Then install the workpiece on the machine tool, and align the clamping position of the workpiece on the machine tool according to the marked line.

This clamping method has low productivity, low precision, and high requirements for workers’ technical level. Generally used for processing complex and bulky parts in single-piece small batch prototype production. Or parts whose blank size tolerance is too large to be directly clamped by a fixture.

(3) Clamping with clamps

The fixture is specially designed in accordance with the requirements of the processed process. 治具上の位置決め要素により、ワークピースが工作機械や工具に対して正しい位置を迅速に占めることができます。, アライメントレスでワークの位置精度を確保できます。. 高い生産性と高い位置決め精度を備えた治具, ただし、特別な治具を設計および製造する必要がある, バッチ生産や大量生産で広く使用されています.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe