カテゴリー: CNC machining of aluminum alloy heat sink

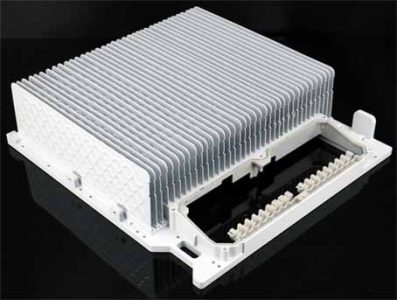

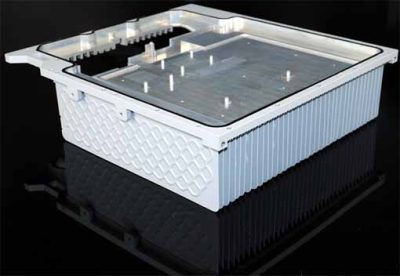

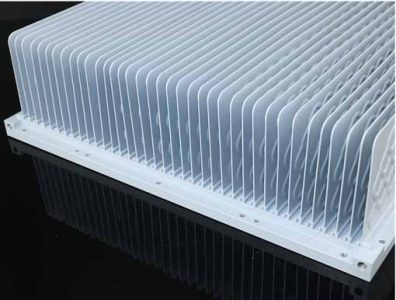

商品名: Aluminum alloy heat sink

加工方法: aluminum alloy cnc processing

材料: アルミニウム合金, アルミニウム, 銅

表面処理: 研磨, バリ取り, 絵画

Machining cycle: 3-7 7営業日

試験基準: 3お客様からご提供いただくD図面

データ形式: STP/IGS/X.T/プロ

製品の特徴: 滑らかな表面, spray paint, 高光沢, 素晴らしい仕上がり, clear lines

ヒートシンクのシェルメーカー

法執行レコーダーのヒートシンクハウジング. このテクノロジーは、法執行機関の実際のニーズを満たすように設計および開発されています。. 警察の個々の法執行レコーダー向けの効率的で実用的な放熱ソリューションです。. 警察の携帯端末に最適です, セキュリティ機器モバイル端末, 監視装置 モバイル端末, 等, 幅広い用途で. 現在の警察法執行用レコーダーのほとんどは、長期間の作業条件下での発熱の問題を克服できません。. 法執行記録の全体的なパフォーマンスを向上させるため, 実際のニーズを利用した経験という意味での法執行機関の記録と同様に, 現在蔓延している市場執行レコーダー熱に対する解決策, 乏しい経験、問題意識;

Further improve the performance of the whole machine, increase the service life of the law enforcement recorder, change the traditional use experience before, and improve the work efficiency of law enforcement officers in the duty.

CNC milling of aluminum heat sink shell

The new technology provides a heat sink and housing for law enforcement recorders.

The utility model is realized through the following measures:

A heat sink for a law enforcement recorder, which is characterized in that it comprises: The square plate body and the heat dissipation end portion vertically arranged on one side of the square plate body, the other three sides of the square plate body are uniformly provided with a plurality of notches, and the outer surface of the heat dissipation end portion is provided with a plurality of heat dissipation protrusions. The heat dissipation protrusion has the function of increasing the contact area with the outside air and improving the heat dissipation effect.

その中で, the heat sink is an integrally formed die casting; the material of the heat sink is aluminum-magnesium alloy.

A fixing hole is arranged on the heat sink, and the heat sink is fixed on the housing of the law enforcement recorder by screws or rivets passing through the fixing holes.

In order to better achieve the above-mentioned purpose of the invention, the present invention also provides a housing for a law enforcement recorder, which includes a frame-shaped housing, a display screen connected to the housing, and a back cover. Wherein, it also includes a heat sink arranged at the lower end of the casing;

A socket is opened on the side wall of the lower end of the housing, the square body of the heat sink is located in the housing, and the outer surface of the heat sink end is exposed to the air; Both ends of the heat dissipation end are provided with fixing holes, the lower end of the housing is provided with mounting holes, and the heat sink is fixed on the housing by screws or rivets passing through the mounting holes and the fixing holes.

Wherein, the outer surface of the side wall of the lower end of the casing is provided with a plurality of positioning protrusions. The inner surface of the heat dissipation end portion is provided with a plurality of positioning sockets that cooperate with the positioning protrusions.

The heat sink is an integrally formed die casting.

Supplier of aluminum heat sink housing

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe