5-銅表面の軸加工

5-axis machining of complex curved parts (アルミニウム合金, ステンレス鋼, 銅, チタン, マグネシウム, 銅)

Several elements of 5-axis machining of complex curved parts: curved surfaces and indexable milling inserts generated on CAD/CAM software

Almost all complex curved surfaces are processed by high-speed milling in production. The purpose is to improve production efficiency, reduce product cost, and at the same time improve the shape accuracy of the workpiece and reduce the surface roughness. In order to meet the needs of high-speed milling, the spindle of the machine tool almost without exception uses an electric spindle. The spindle speed is continuously variable according to the diameter of the tool used, and the speed range is from several thousand revolutions per minute to tens of thousands of revolutions per minute. The drive system of the sliding table is also different from conventional machining centers in high-speed milling. Commonly used systems include high-speed screw nut pair drive and linear motor drive, and the maximum feed speed can reach more than 100m/min.

5-インペラ曲面の軸加工

When processing complex curved surfaces, the CNC system of the machine tool must also meet some special requirements. 例えば, NC machining programs for complex curved surfaces are generally generated on CAD/CAM software. A curved surface program often requires several megabytes (Byte) of storage space, and it is no longer possible to transfer the NC program with a floppy disk. したがって, the numerical control system must have the function of networking with other computer systems in order to directly receive numerical control programs from CAD/CAM. 加えて, the numerical control system must also adopt advanced control technology, first of all, it requires the look-ahead (LookAhead) function. 言い換えると, before the machine tool processes a certain track, the data system analyzes the surface to be processed in advance, according to the curvature of each point on the surface and the connection relationship between adjacent points. Properly adjust the feed speed of the machine tool to achieve the highest productivity while ensuring the accuracy of the workpiece. In order to reduce the dynamic error in the machining process, the new type of data system servo error correction no longer uses the previous series proportional differential integral (PID) regulator. Instead, it uses a state regulator that compensates for state parameters such as position and speed. The use of this regulator can completely eliminate the drive lag error, ギャップや摩擦によって生じる非線形誤差を補正します。, 工作機械の特定の振動も相殺します. ワークの形状精度の向上と面粗さの低減の要求に応えるため.

CNC milling cutter for machining curved surfaces

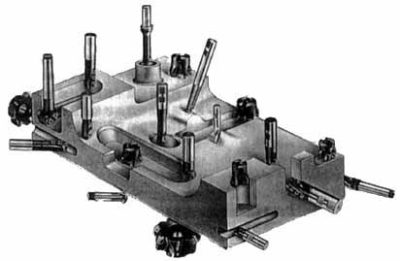

The tool system plays a decisive role in the production efficiency and processing quality when processing complex curved surfaces. 切削工具システムを選択する場合, まず、処理する部品の形状から開始する必要があります, さまざまな種類の切削工具を合理的に使用する. As for the workpiece shown in Figure 1, the geometric variability of each part is very different. ボールエンドミルのみで加工する場合, 小径のボールエンドミーリングカッターを選択する必要があります, 処理効率の向上が困難になる. 加えて, the arc radius of some parts is so small that it cannot be processed even with a small ball-end milling cutter. したがって, 生産効率とワーク形状の両方の要件を考慮して, other types of milling cutters, エンドミルや三面フライスなど, must be equipped on the five-axis machining center for processing complex curved surfaces.

5-axis milling of different surfaces

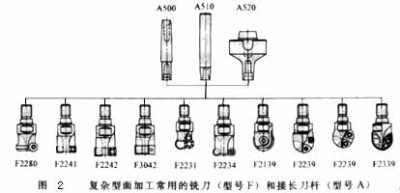

形 2 shows some of the selected milling cutter types. サイズが許す限り, regardless of the shape of the milling tool, the cutting edge should be a machine-clamped indexable milling insert. Such knives can be combined with blades and bodies, and the blades and bodies can be produced by different companies. したがって, a large-scale specialized production can be formed, which is not only conducive to improving the quality of the tool, but also conducive to reducing the production cost of the tool.

The tool life is closely related to the feed rate, cutting speed and milling depth. The optimal milling amount is often a small range, which should be determined according to the specific tool and workpiece material.

加えて, cutting strategies such as: Tool path planning, tool axis surface normal vector (the surface normal direction at this point) or along the surface tangent vector (surface tangent direction at this point) is also a key factor for processing complex surfaces. 加工ワークの表面粗さに影響を与えるだけではありません, ワークの形状や寸法精度にも影響します. 形 3 shows the different cutting strategies used when machining a cylindrical curved surface. For milling in the circumferential direction, the tool path needs to be interpolated with two-axis linkage. 母線方向に沿って切断する場合, ツールは単軸補間を実行するだけで済みます。. 加えて, 切削方法が異なると工具の摩耗に大きな違いが生じます: The tool wear during down milling is significantly lower than that of up-down milling, 往復フライス加工中の摩耗は、一方向フライス加工の摩耗よりもはるかに大きくなります。.

加工工程の安定性を向上させるため, the continuity of cutting must be ensured when optimizing the cutting strategy. 同時に, reduce the cutting motion and idle stroke as much as possible to shorten the milling time. When rough milling steel parts, it is necessary to ensure continuous down milling to minimize the peak value of the cutting edge during the cutting process.

図のようなワークを加工する場合 4, if the row cutting and milling track shown in Figure 5a is used for partition processing; ツールの動きが非常に無理がある, 切断条件が非常に不十分です, the machining time is 33min, ワークピースの表面粗さは6〜9μmです. If the circle cutting track shown in Figure 5b is used instead for processing, 処理時間は約です 27 分, and the roughness of the workpiece can also be reduced to 2 に 4 μm.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe