Prima della progettazione del percorso utensile di fresatura a 5 assi, la precisione del sistema del modello CAD 3D dovrebbe essere impostata quanto più alta possibile. Soprattutto quando si effettua la conversione del modello tra diversi sistemi CAD, CATIA (*.modello) formato e Parasolid (*.x_t) formato sono preferiti per la conversione dei dati. In secondo luogo, utilizzare il formato IGES per la conversione dei dati. Quando si utilizza il formato IGES, la precisione del sistema generalmente non deve essere inferiore a 0,01 mm. Soprattutto quando si esegue il taglio ad alta velocità a cinque assi di pezzi di precisione, l'accuratezza del modello e l'accuratezza dell'interpolazione dell'utensile hanno un impatto importante sull'output del percorso utensile.

Numerical control processing of spatial curved surface involves a lot of content, especially when it comes to 5-axis processing. The five-axis machining involves key technologies such as machining guide surface, interference surface, trajectory restriction area, tool advance and retreat, and tool axis vector control. The basis of four-axis and five-axis machining is to understand the vector change of the tool axis. One of the key technologies for 4-axis and 5-axis machining is how the vector of the tool axis (the axis vector of the tool axis) changes in space. The vector change of the tool axis is realized by the swing of the swing table or spindle. For fixed-axis milling where the vector does not change, the product can be processed by 3-axis milling. The key to 5-axis machining is to control the constant change of the tool axis vector in space or make the tool axis vector and the original coordinate system of the machine form a certain angle in space, and use the side or bottom edge of the milling cutter to cut. The vector change control of the tool axis generally has several methods as shown in Figure 3:

Key points of 5-axis tool path design

① Line: The vector direction of the tool axis is parallel to a fixed angle formed by a straight line in space;

② Pattern Surface: The surface normal is that the vector of the tool axis always points to the normal direction of the surface;

③ From point: The vector of the point control tool axis is far away from a certain point in space; Topoint: The vector of the tool axis points to a point in space;

④ Swarf Driver: The vector of the tool axis changes along the ruled direction of the space surface (the surface is ruled);

⑤ Vector continuous interpolation control of tool axis. From the point of view of the vector control mode of the above-mentioned tool axis, the cutting mode of 5-axis CNC milling can carry out reasonable tool path design planning according to the actual product processing.

Comparison of 3-axis linkage and 5-axis linkage processing product processing

UGII / Contour Milling When three-axis high-speed contour milling, the arc transition between tool paths. High-speed milling support: The contour layered machining provided by the system is used in high-speed milling occasions. The corners are transitioned in the form of rounded corners to avoid 90 degree sharp rotation (high-speed occasions are easy to damage the guide rail and the motor). Allo stesso tempo, the spiral feed and retreat is adopted, and the system also provides multiple methods such as surround to support the generation strategy of high-speed machining tool path. UGII / Variable Axis Milling The variable axis milling module supports fixed axis and multi-axis milling functions. Any geometry generated in the UGII modeling module can be processed and the correlation of the main model can be maintained. This module provides 3~5 axis milling functions that have been verified by many years of engineering use, and provides tool axis control, tool feed mode selection and tool path generation functions. The vector control mode and processing strategy of the tool axis.

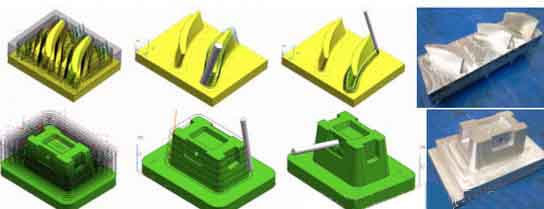

The UGII / Sequential Milling module can realize the control of each step in the tool path generation process, support 2~5 axis milling programming, and is completely related to the UGII master model. In an automated way, it obtains absolute control similar to APT direct programming, allowing users to interactively generate tool paths section by section, and maintain control of each step in the process. The provided cycle function allows users to define only the innermost and outermost tool paths on a certain surface, and the module automatically generates intermediate steps. This module is a unique UGII module with functions such as automatic root cleaning in the UGII CNC machining module, and is suitable for difficult CNC programming. Come mostrato in figura 4, the tool trajectories of 3-axis linkage and 5-axis linkage machining and the actual product processing are shown respectively.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe