Impostare la quantità di taglio della fresa in acciaio ad alta velocità per la fresatura dell'acciaio inossidabile e la scelta della fresa

Prima di tutto, il liquido refrigerante raffredderà i trucioli troppo rapidamente e si fonderanno nella lama, con conseguente riduzione della durata dell'utensile;

Una velocità di avanzamento troppo elevata causerà un accumulo di materiale, mentre una velocità di avanzamento troppo bassa causerà attrito tra l'utensile e il pezzo, e causerà anche il surriscaldamento.

Infatti, per evitare il filo del coltello, È necessario il calore di taglio dell'acciaio inossidabile con lavorazione CNC. Per frese in acciaio inox, è necessario selezionare la velocità di macinazione appropriata per conferire ai trucioli un colore marrone chiaro.

If the chips turn dark brown, it indicates that the cutting speed has reached the maximum limit. It is necessary to pay attention to the cutting speed when selecting the milling cutter when CNC machining stainless steel.

Parametri di fresatura ad alta velocità di parti in acciaio inossidabile

Cutting tools should be rigid, advanced, and have the highest possible overload capacity. It is best to mill stainless steel below 75% of the machine’s load calibration capacity.

Both the workpiece and the tool should be clamped firmly, and the extension of the tool should be as short as possible. Additional supports can be used if necessary. Whether it is a high-speed steel tool or a cemented carbide tool, it should be sharp at all times. It’s best to sharpen regularly, and don’t sharpen it when you have to.

Should use good performance lubricating fluid, such as chlorinated petroleum grease. This lubricant is particularly effective for powerful cutting where the feed rate is relatively slow.

For high-speed finishing cutting, it is recommended to use kerosene to dilute this lubricant. This mixed cutting fluid can keep the workpiece and tool at a lower temperature. Special attention should be paid to the cutting of Cr-Ni austenitic stainless steel. When cutting this stainless steel, you should be as careful as possible. It is possible to perform forced cutting to avoid pauses, so as not to cause work hardening and material slippage.

Le caratteristiche della fresatura dell'acciaio inossidabile sono: The adhesion and melting of stainless steel are strong, ed i trucioli aderiscono facilmente ai denti della fresa, which deteriorates the cutting conditions; Durante la fresatura ascendente, i denti della fresa scivolano prima sulla superficie indurita, che aumenta la tendenza all’incrudimento; Durante la fresatura, l'impatto e le vibrazioni sono grandi, che rende i denti della fresa facili da scheggiare e usurare.

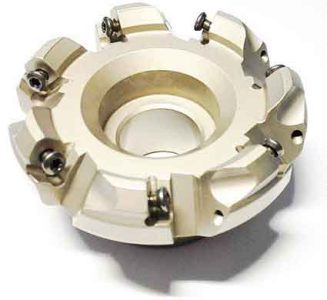

Milling tool for milling stainless steel parts

Per la fresatura dell'acciaio inossidabile, except for end mills and some end mills, which can use cemented carbide as the material of the milling cutter teeth, the other types of milling cutters all use high-speed steel. In particolare, tungsten-molybdenum series and high-vanadium high-speed steel have good effects, and the tool durability can be increased by 1 A 2 times compared with W18Cr4V. Cemented carbide grades suitable for making stainless steel milling cutters are YG8, YW2, 813, 798, YS2T, YS30, YS25, eccetera.

Quando si fresa l'acciaio inossidabile, the cutting edge must be sharp and able to withstand impact, and the chip pocket must be large. Large helix angle milling cutters (cylindrical milling cutters, end milling cutters) can be used, the helix angle b is increased from 20° to 45° (n=5°), and the tool durability can be increased by more than 2 volte. , Because at this time the working rake angle g0e of the milling cutter increases from 11° to over 27°, the milling is brisk. But the value of b should not be too large, especially for end mills with b≤35°, so as not to weaken the teeth.

Use wave-edge end mills to process stainless steel pipes or thin-walled parts. The cutting is brisk, the vibration is small, the chips are fragile, e il pezzo non è deformato. La fresatura ad alta velocità con frese in metallo duro e l'acciaio inossidabile con frese indicizzabili può ottenere buoni risultati.

Milling 1Cr18Ni9Ti with a silver-white chip (SWC) end mill, i suoi parametri geometrici sono gf=5°, gp=15°, di=15°, p=5°, kr=55°, k′r=35°, g01= -30°, bg=0,4 mm, re=6mm. When Vc=50~90 m/min, Vf=630~750mm/min, and a’pb can reach 20=2~6mm, the milling power is reduced by 44% and the efficiency is greatly improved. Il principio è quello di rettificare uno smusso negativo sul tagliente principale, and artificially generate a built-up edge during milling, so that it can replace the cutting edge for cutting, and the rake angle of the built-up edge is ~~302. Due to the effect of the entering angle, the built-up edge is subjected to a thrust parallel to the cutting edge generated on a rake face and becomes a secondary chip flowing out, thereby taking away the cutting heat and reducing the cutting temperature.

Quando si fresa l'acciaio inossidabile, down milling should be used as much as possible. The asymmetric down milling method can ensure that the cutting edge is smoothly cut away from the metal, and the contact area of the chip bonding blade is small. Under the action of high-speed centrifugal force, the chips are easily thrown away, so that when the cutter teeth re-cut into the workpiece, the chips impact the rake face and cause the phenomenon of blade spalling and chipping.

The spray cooling method has the most significant effect, che può aumentare la durata della fresa di oltre il doppio; Se un generale 10% l'emulsione viene utilizzata per il raffreddamento, la portata del fluido da taglio deve essere garantita per ottenere un raffreddamento sufficiente. Quando la fresa in metallo duro fresa l'acciaio inossidabile, take Vc=70~150 m/min and Vf=37.5~150 mm/min. Allo stesso tempo, appropriate adjustments should be made according to the alloy grades and workpiece materials.

share to:

| Tipo di fresa | Milling cutter diameter D (mm) |

Rotating speed n (giri/min) |

Feed rate F (mm/min) |

Osservazioni |

| Fresa | 3-4 5-6 8-10 12-14 16-18 20-25 32-36 40-50 |

1180-750 750-475 600-375 375-235 300-235 235-190 190-150 150-118 |

Manuale Manuale Manuale 30-37.5 37.5-47.5 47.5-60 47.5-60 47.5-75 |

1) When the milling width and cutting depth are small, the feed amount is larger; Otherwise, take the small value 2) For milling cutters with three-sided edges, please refer to the same diameter disc milling cutter to select the cutting speed and feed 3) When the milling cutter is 2Cr13, the cutting amount can be adjusted according to the actual hardness of the material 4) When milling and cutting concentrated nitric acid resistant stainless steel, both n and f should be appropriately lowered. |

| Disc milling cutter | 75 110 150 200 |

235-150 150-75 90-60 75-37.5 |

23.5 or manual 23.5 or manual 23.5 or manual 23.5 or manual |

– |

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe