CNC precision machining mainly includes fine turning, fine boring, fine milling, fine grinding and grinding processes:

(1) Fine turning and fine boring: Most of the precision light alloy (aluminum or magnesium alloy, eccetera.) parts in the aircraft are mostly processed by this method. Generalmente, natural single crystal diamond tools are used, and the radius of the blade arc is less than 0.1 micron. Machining on a high-precision lathe can obtain an accuracy of 1 micron and a surface unevenness with an average height difference of less than 0.2 micron, and the coordinate accuracy can reach ±2 microns.

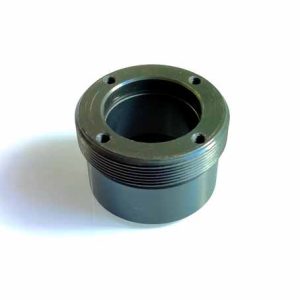

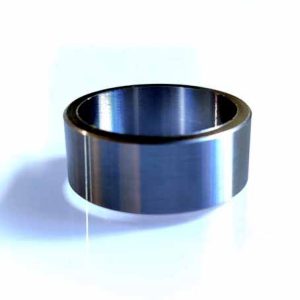

Machining and grinding of non-standard steel, lega, acciaio inossidabile: pistons, turbine sleeves, fixed sleeves, spacer rings, washers, shaft mounts, metal gears, piston cylinders (blackening/phosphating)

Precision piston grinding |

Plating treatment of turbine sleeve |

Blackening and phosphating of the fixed sleeve |

Spacer ring, washer |

Shaft fixing seat |

Metal gear |

(2) Fine milling: used to process aluminum or beryllium alloy structural parts with complex shapes. Rely on the precision of the machine tool’s guide rail and spindle to obtain high mutual position accuracy. High-speed milling using a finely ground diamond head can obtain a precise mirror surface.

(3) Fine grinding: used for machining shaft or hole parts. Most of these parts are made of hardened steel, which has high hardness. Most high-precision grinding machine spindles use static pressure or dynamic pressure liquid bearings to ensure high stability. The ultimate accuracy of grinding is not only affected by the rigidity of the machine tool spindle and bed, but also related to the selection and balance of the grinding wheel, and the machining accuracy of the center hole of the workpiece. Fine grinding can obtain a dimensional accuracy of 1 micron and an out-of-roundness of 0.5 micron.

(4) Rettifica: Use the principle of mating parts to selectively process irregular convex parts on the processed surface. Abrasive particle diameter, cutting force and cutting heat can be precisely controlled, so it is the highest precision machining method in precision machining technology. The hydraulic or pneumatic fittings in the precision servo parts of the aircraft, and the bearing parts of the dynamic pressure gyro motor are all processed in this way. To achieve an accuracy of 0.1 or even 0.01 microns and a microscopic unevenness of 0.005 micron.

CNC machining of piston cylinder

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe