CNC machining parts, PCB board milling positioning design

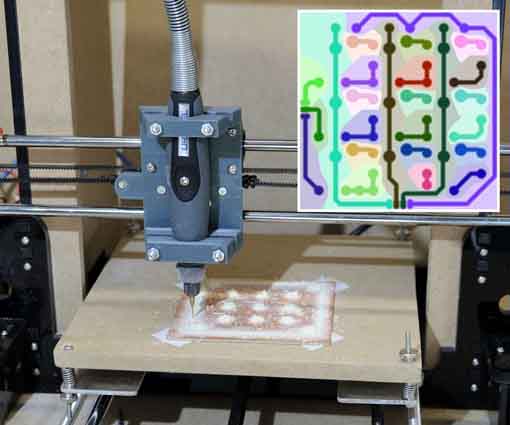

The so-called positioning of CNC milling is to use positioning pins to position the printed circuit board to be processed on the worktable of the milling machine, so as to conveniently and accurately CNC machine the shape of the part. Simple and reliable positioning is required, and parts can be quickly loaded and unloaded while removing chips. There are many positioning methods: If some milling machines are designed with a reciprocating worktable, when one workbench is processing, the other workbench loads and unloads parts. There are two sets of milling plate positioning method used. When one milling positioning pad is processed on the CNC milling table, the other milling positioning pad is loaded and unloaded on the platform. The exchange of the two takes only a few seconds.

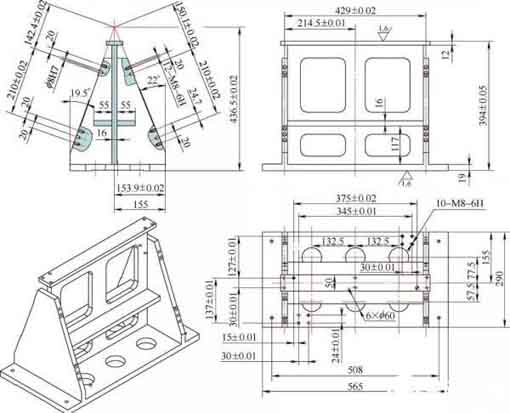

Positioning design of CNC milling parts

The CNC milling table itself is a positioning plate during parts processing. It is an aluminum alloy plate positioned by pins and fixed by screws. There is a hole-slot positioning system on the worktable under each CNC milling spindle. The milling pad is actually an intermediate positioning fixture, sometimes called “soft positioning”. It is required to be able to locate reliably and quickly unload parts, reduce auxiliary time and improve production efficiency. Before the contour is milled, a groove with the same dimensions as the shape of the part is pre-milled on the milling pad. En général, the dimension of the groove width is the diameter of the actual milling cutter plus 0.5 mm. The groove depth is 2.5mm. Dans le processus d'usinage, it is a path of the milling cutter motion track. As the vacuum cleaner absorbs dust, an air flow is generated in the groove to remove the chips, make the processed more smooth, prevent the chips from blocking the chip groove of the milling cutter, and reduce the edge. Lors du traitement, make the milling cutter extend into the groove by 1.5-2mm. This prevents the end wear from being worn by the milling cutter continuously cutting into the part. The diameter reduction and the reduction of the end diameter allowed by the milling cutter manufacturing cause the deviation of the part processing size.

Before the parts are mass produced, the milling backing plate is installed on the CNC milling table and the new nylon thread plug is screwed on. Drill holes on the threaded plug and install the positioning pin to use. The chip groove on the milling pad is deeper and wider, which is more conducive to smooth air flow, chip removal, and smoother surface to be processed. Cependant, the supporting surface is weakened, especially when the chip flute is close to the positioning pin, which will make the positioning unstable.

Most of the milling pads in the design of hardware parts use non-metal laminates. The material is relatively soft. When the pins are repeatedly loaded and unloaded, the positioning holes are worn and enlarged. Par exemple, semi-specific and consumable milling pads work under such conditions.

Généralement, the pin is press-fitted on the milling pad, and the interference is 0.005~0.01mm. If it is a special milling pad or a high-density fiberboard as the milling pad, a tighter fit is better. But for semi-specific milling pads or consumable milling pads, the interference is greater than 0.007mm. When the pin is press-fitted, it is possible to cut off part of the base material in the pin hole to form a deep groove or gap. With repeated loading and unloading of pins, the pin holes of the laminate also have delamination or chipping. When milling parts, most of the cutting force is borne by the positioning pins. This lateral pressure squeezes the pin holes and the defects in the holes make the pins loose and deviate one by one. It directly affects the external dimensions of the printed board and cannot guarantee strict tolerances.

Positioning design of CNC milling PCB board

The smaller the diameter of the positioning pin, the greater the relative deflection. Donc, large diameter holes should be used as positioning holes as much as possible. The diameter and deflection of the positioning pin also directly affect the productivity. Par exemple, a stack of four PCB boards was originally designed to be milled at one time. Due to the small diameter of the pin and the large amount of deflection, three PCB boards had to be milled to reduce the efficiency by 25%.

In the process of PCB prototype processing, the positioning pins should be closely matched to ensure reliable positioning of the processing board. Instead of relying on the help of adhesive tape or adhesive, it takes time to bond and cure. Tight fit also means strict tolerances, and precision can also be guaranteed by milling multilayer boards or high-quality double-sided boards.

En général, the drill diameter is the lower deviation, which is generally 0~0.005mm, and some is 0~0.01mm. Most non-metal laminates have a certain amount of shrinkage after drilling, usually 0.005 to 0.007mm. Such a hole with a lower deviation of 0.005~0.01mm with standard pins can produce an interference of 0.005mm. Donc, there is no need to consider special processing technology, nor to measure the diameter of the drill bit one by one, and select a small-diameter drill bit to meet the requirements of press fit and save time.

Par exemple, a certain 1.6mm thick printed circuit board, with a tolerance of ±0.013mm, mills a stack of four PCB boards each time. The hole position tolerance is +/-0.025mm, and the hole diameter difference is ±0.025mm, using standard pins. Then loading and unloading PCB boards is difficult and time-consuming. Because it is possible to lock the pin in the milled plate. This example points out that the pin and the quilt should be fitted with a looser slip fit. Bien sûr, if the gap is too large, it will affect the machining accuracy and edge smoothness.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe