(1) NC machining track method

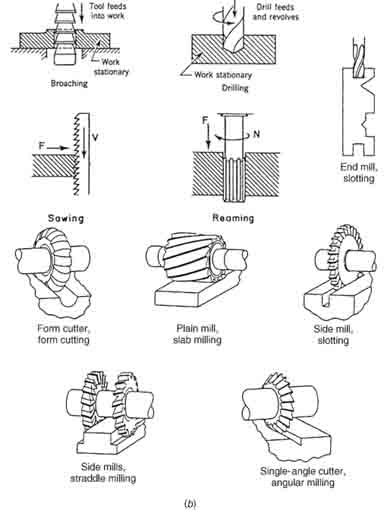

This machining method uses the trajectory of the tool tip movement to form the shape of the machined surface. Ordinary turning, jyrsintä, planing and grindig all belong to the tool tip path method. The shape accuracy obtained by this method mainly depends on the accuracy of the forming movement.

(2) Forming method of CNC machining

Use the geometry of the forming tool to replace certain forming movements of the machine tool to obtain the shape of the machined surface. Such as forming turning, jyrsintä, hiominen, jne. The shape accuracy obtained by the forming method mainly depends on the shape of the tool edge.

(3) Sports development method

Using the tool and the workpiece to generate the include surface formed by the movement to obtain the shape of the machined surface. Such as gear hobbing, gear shaping, gear grinding, and knurling splines are all kinematic generation methods. The shape accuracy obtained by this method mainly depends on the shape accuracy of the cutting edge and the accuracy of the generated motion.

Tool tip path method for turning, jyrsintä, planing and grinding

3. Method of obtaining position accuracy

In machining, the accuracy of the position of the processed surface on other surfaces is mainly determined by the clamping of the workpiece.

(1) Directly find the correct clamping

This method is to use a dial indicator, a marking plate or visual inspection to directly locate the workpiece on the machine tool.

(2) Mark the line to find the formal clamping

This method first draws the center line, the symmetry line and the processing line of each surface to be processed on the blank according to the part drawing. Then install the workpiece on the machine tool, and align the clamping position of the workpiece on the machine tool according to the marked line.

This clamping method has low productivity, low precision, and high requirements for workers’ technical level. Generally used for processing complex and bulky parts in single-piece small batch prototype production. Or parts whose blank size tolerance is too large to be directly clamped by a fixture.

(3) Clamping with clamps

The fixture is specially designed in accordance with the requirements of the processed process. The positioning element on the fixture can make the workpiece quickly occupy the correct position relative to the machine tool and the tool, and the positioning accuracy of the workpiece can be ensured without alignment. Fixtures have high productivity and high positioning accuracy, but special fixtures need to be designed and manufactured, which are widely used in batch and mass production.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe