Establezca la cantidad de corte de la fresa de acero de alta velocidad para fresar acero inoxidable y la elección de la fresa

En primer lugar, el refrigerante enfriará las virutas demasiado rápido y se fusionará con la cuchilla, lo que resulta en una vida útil reducida de la herramienta;

Too high a feed rate will cause material accumulation, while a too low feed rate will cause friction between the tool and the workpiece, and will also cause overheating.

De hecho, in order to avoid the edge of the knife, CNC machining stainless steel cutting heat is necessary. For stainless steel milling cutters, the appropriate milling speed should be selected to make the chips have a light brown color.

If the chips turn dark brown, it indicates that the cutting speed has reached the maximum limit. It is necessary to pay attention to the cutting speed when selecting the milling cutter when CNC machining stainless steel.

Parámetros del fresado de piezas de acero inoxidable a alta velocidad.

Cutting tools should be rigid, advanced, and have the highest possible overload capacity. It is best to mill stainless steel below 75% of the machine’s load calibration capacity.

Both the workpiece and the tool should be clamped firmly, and the extension of the tool should be as short as possible. Additional supports can be used if necessary. Whether it is a high-speed steel tool or a cemented carbide tool, it should be sharp at all times. It’s best to sharpen regularly, and don’t sharpen it when you have to.

Should use good performance lubricating fluid, such as chlorinated petroleum grease. This lubricant is particularly effective for powerful cutting where the feed rate is relatively slow.

For high-speed finishing cutting, it is recommended to use kerosene to dilute this lubricant. This mixed cutting fluid can keep the workpiece and tool at a lower temperature. Special attention should be paid to the cutting of Cr-Ni austenitic stainless steel. When cutting this stainless steel, you should be as careful as possible. It is possible to perform forced cutting to avoid pauses, so as not to cause work hardening and material slippage.

Las características del fresado de acero inoxidable son: The adhesion and melting of stainless steel are strong, y las virutas son fáciles de adherir a los dientes de la fresa, which deteriorates the cutting conditions; Al fresar, Los dientes del cortador se deslizan primero sobre la superficie endurecida., lo que aumenta la tendencia al endurecimiento por trabajo; Al fresar, el impacto y la vibración son grandes, lo que hace que los dientes de la fresa sean fáciles de astillar y desgastar.

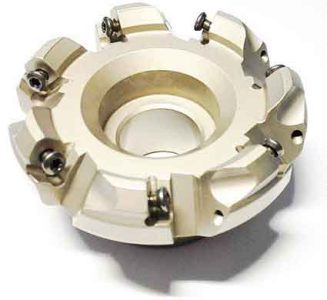

Milling tool for milling stainless steel parts

Para fresar acero inoxidable, except for end mills and some end mills, which can use cemented carbide as the material of the milling cutter teeth, the other types of milling cutters all use high-speed steel. In particular, tungsten-molybdenum series and high-vanadium high-speed steel have good effects, and the tool durability can be increased by 1 a 2 times compared with W18Cr4V. Los grados de carburo cementado adecuados para fabricar fresas de acero inoxidable son YG8., YW2, 813, 798, YS2T, YS30, YS25, etc..

Al fresar acero inoxidable, the cutting edge must be sharp and able to withstand impact, y el bolsillo para las fichas debe ser grande. Fresas de ángulo de hélice grande (fresas cilíndricas, cortadores de fresado) puede ser usado, el ángulo de hélice b aumenta de 20° a 45° (n=5°), y la durabilidad de la herramienta se puede aumentar en más de 2 veces. , Because at this time the working rake angle g0e of the milling cutter increases from 11° to over 27°, la molienda es rápida. Pero el valor de b no debería ser demasiado grande., especialmente para fresas con b≤35°, para no debilitar los dientes.

Use wave-edge end mills to process stainless steel pipes or thin-walled parts. The cutting is brisk, the vibration is small, the chips are fragile, y la pieza de trabajo no está deformada. El fresado de alta velocidad con fresas de carburo cementado y el acero inoxidable con fresas indexables pueden lograr buenos resultados..

Milling 1Cr18Ni9Ti with a silver-white chip (SWC) end mill, sus parámetros geométricos son gf=5°, gp=15°, de=15°, ap=5°, kr=55°, k′r=35°, g01= -30°, fondo = 0,4 mm, re=6mm. When Vc=50~90 m/min, Vf=630~750mm/min, and a’pb can reach 20=2~6mm, the milling power is reduced by 44% and the efficiency is greatly improved. The principle is to grind a negative chamfer on the main cutting edge, and artificially generate a built-up edge during milling, so that it can replace the cutting edge for cutting, and the rake angle of the built-up edge is ~~302. Due to the effect of the entering angle, the built-up edge is subjected to a thrust parallel to the cutting edge generated on a rake face and becomes a secondary chip flowing out, thereby taking away the cutting heat and reducing the cutting temperature.

Al fresar acero inoxidable, down milling should be used as much as possible. The asymmetric down milling method can ensure that the cutting edge is smoothly cut away from the metal, and the contact area of the chip bonding blade is small. Under the action of high-speed centrifugal force, the chips are easily thrown away, so that when the cutter teeth re-cut into the workpiece, the chips impact the rake face and cause the phenomenon of blade spalling and chipping.

The spray cooling method has the most significant effect, which can increase the durability of the milling cutter by more than double; If a general 10% emulsion is used for cooling, the cutting fluid flow rate should be ensured to achieve sufficient cooling. When the carbide milling cutter mills stainless steel, take Vc=70~150 m/min and Vf=37.5~150 mm/min. Al mismo tiempo, appropriate adjustments should be made according to the alloy grades and workpiece materials.

share to:

| Type of milling cutter | Diámetro de la fresa D (milímetros) |

Rotating speed n (r/min) |

Tasa de alimentación f (mm/min) |

Remarks |

| End mill | 3-4 5-6 8-10 12-14 16-18 20-25 32-36 40-50 |

1180-750 750-475 600-375 375-235 300-235 235-190 190-150 150-118 |

Manual Manual Manual 30-37.5 37.5-47.5 47.5-60 47.5-60 47.5-75 |

1) When the milling width and cutting depth are small, the feed amount is larger; De lo contrario, take the small value 2) For milling cutters with three-sided edges, please refer to the same diameter disc milling cutter to select the cutting speed and feed 3) When the milling cutter is 2Cr13, the cutting amount can be adjusted according to the actual hardness of the material 4) When milling and cutting concentrated nitric acid resistant stainless steel, both n and f should be appropriately lowered. |

| Disc milling cutter | 75 110 150 200 |

235-150 150-75 90-60 75-37.5 |

23.5 or manual 23.5 or manual 23.5 or manual 23.5 or manual |

– |

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe