Turning and milling combined technology

¿Qué es el mecanizado?? Comparación de torneado, Molienda, y Perforación

El torno y la fresadora son dos herramientas que se utilizan para cortar y mecanizar diferentes tipos de materia prima en una gran variedad de sectores. A pesar de ser muy común en la industria., Todavía hay dudas sobre cuáles son sus diferencias y por qué a veces se les etiqueta como “CNC” y otras no.. Vamos a responder estas preguntas por ti.!

Para cortar materia prima se utilizan tornos y fresadoras., pero tienen formas muy diferentes de hacerlo. Los tornos giran el material., mientras que una fresadora utiliza una herramienta rotativa para diversas operaciones de corte. Para usar cualquiera de los dos, debes conocer las diferencias entre ambos y lo que cada uno es capaz de hacer.

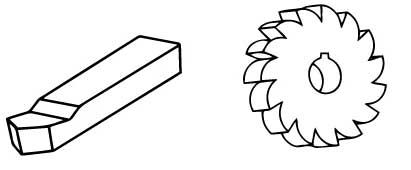

Tool comparison for turning and milling

DIFFERENCES BETWEEN LATHE AND MILLING MACHINE

Lathes are machines that produce a continuous rotation in the material to be worked, while the milling machine is a rotating tool that performs different cutting operations.

Thus, the main difference between lathe and milling machine is that with the lathe you create cylindrical pieces, while with the milling machine you can make pieces of all kinds of shapes. In a lathe, the raw material rotates on a plate and the tool cuts and shapes. In a milling machine, the material is parked while the cutter rotates, removing excess material.

This is explained because the milling machine generally works on three axes X, Y and Z and the lathe only on two axes, X and Z. De este modo, the lathe only machines radially by rotating the part, and the milling machine does it. by means of a fixed head and what moves is the bench where the piece is. The milling machine can even work with 4 or 5 ejes, as we explain in this article about which milling machine to buy according to its number of axes.

Comparación de piezas torneadas y fresadas.

Tool comparison for turning and milling

WHAT IS THE MACHINE YOU NEED FOR YOUR WORKSHOP?

For work with cylindrical shapes, the use of a lathe is more convenient, while when cutting straight or at an angle it is preferable to use a milling machine. Even so, both the lathe and the milling machine are two necessary machines for the machining industry.

Milling is much more versatile, since it allows all surfaces to be machined regardless of their shape (flat, convex, concave, etc.). Por otro lado, the lathe only works with cylindrical parts.

En conclusión, if you need to create pieces of different shapes, the milling machine will be the most profitable machine, while if you are only going to work on cylindrical pieces, the lathe will suffice. Por supuesto, before buying a machine think about the scalability of your business and the possibilities for the future. If you have doubts about which one you need, at KANGDING we offer you a free consultation so that you can explain your situation to us and our professionals will advise you on which is the best solution for you.

Characteristics

Lathes create cylindrical parts using ID and OD cutting tools of different sizes and shapes. The material rotates on a chuck while a tool cuts through the material completely. The tool is secured on the tool post or on the grinder.

A milling machine rotates the tool to cut material that is held stationary in a fixture or vise. Milling machines use cylindrical cutting tools, such as end mills and radial drills, to remove material to make a finished part.

Cutting tools

The main tool used on a lathe is a cutter insert, which uses a removable tip to cut and shape the outside of the material by rotating in the chuck jaws. This type of cutting tool is not used in a milling machine. The type of tools most commonly used in it is the radial milling cutter, which is placed on the shaft and rotates at different speeds, depending on the type of material to be cut. Radial cutters can be used on lathes, but are generally only used on the shaft of a milling machine.

Considerations

If you need to cut material that is cylindrical, you could opt for a lathe. It is better to hold the work and cutting the material will be much easier due to the nature of the machine. You can only drill on the center with a lathe, so if you need an off-center hole or make straight cuts in metal, you will be better off putting that material in a vise or accessory and cutting it with a milling machine. Angle cuts and whatever is needed to remain non-cylindrical, it will be better to cut on a router.

Set up

Setting up a lathe involves less precision, as the chuck itself will center the part to be cut. When installing the chuck jaws, make sure they are equidistant from the center. This will avoid any mistakes during cutting.

To use a milling machine, you must measure the vise or accessory to make sure it is straight. To do this, use an indicator on the shaft and press the vise until it is perfectly straight. Retighten the retaining bolts and recheck for straightness, making any adjustments that are necessary.

Turning technology

Milling technology

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe