1. Programación manual de mecanizado CNC.

Completa manualmente todo el trabajo de programación. (incluido el cálculo numérico asistido por ordenador) para programación manual.

Para piezas con formas geométricas simples., el cálculo numérico es más sencillo y no hay muchos segmentos de programa. La programación manual es más fácil de completar, económico y oportuno. Por lo tanto, La programación manual todavía se usa ampliamente en el procesamiento de puntos y el procesamiento de contornos compuestos de líneas rectas y arcos.. Pero para piezas con formas complejas, especialmente piezas con curvas no circulares, curvas tabulares o superficies curvas, la programación manual es difícil. La posibilidad de errores aumenta, la eficiencia es baja, y a veces ni siquiera el programa se puede compilar. Por lo tanto, automatic programming must be used to compile the program.

The process of NC programming

2. Automatic programming of CNC machining

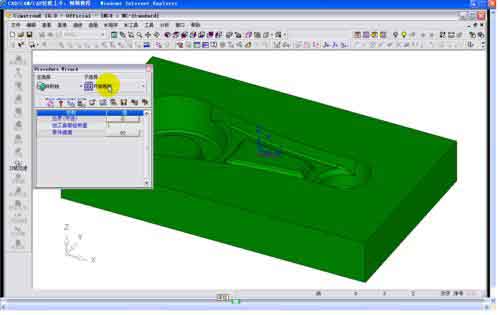

The automatic programming of CNC machining is also called computer-aided programming, eso es, most or all of the programming is done by the computer. Such as completing the calculation of coordinate values, compiling part processing procedures, automatically outputting and printing processing procedures and preparing control media. The self-programming method reduces the labor intensity of the programmer, shortens the programming time, improves the programming quality, and at the same time solves the programming problems of many complex parts that cannot be solved by manual programming. The more complex the surface shape of the workpiece and the more complicated the process, the more obvious the advantages of automatic programming.

Método de programación automática CNC

Steps of CNC programming

1. Determine the process

Analyze the part drawing, determine the processing plan, determine the processing sequence, design the fixture, select the tool, determine the tool path, cantidad de corte, etc.. Correctly select the tool setting point and cutting method.

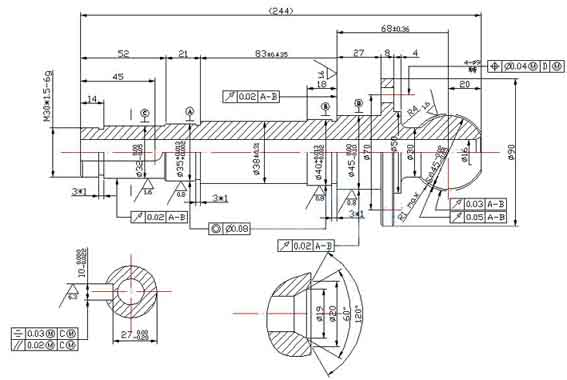

2. Numerical calculation

According to the determined processing route and the allowable part processing error, the required data input to the numerical control device is calculated, which is called numerical calculation. The main content of numerical calculation is to calculate the coordinate value of the part contour and the tool motion path in the specified coordinate system.

Contour machining for parts with simple shapes (such as parts composed of straight lines and arcs). It is necessary to calculate the coordinate values of the start point, end point of the geometric element, the center of the arc, the intersection or tangent point of the two geometric elements. Contour processing for parts with complex shapes (such as parts composed of non-circular curves and curved surfaces). It needs to be approximated by a straight line segment or a circular arc segment, and the node coordinate value is calculated according to the required accuracy. In this case, computers are generally used to complete numerical calculations.

3. Write the program table for parts processing

Write the program according to the code and format specified by the CNC system used.

4. Programmable preparation control medium

En el pasado, perforated tape was used as the medium and fed into the numerical control system through a paper tape reader. Now you can directly use the keyboard to input, or program in the computer through the corresponding software and interface.

5. Program verification and trial cutting

The program must be checked, verified and cut before it can be used.

You can check whether the trajectory is correct through the dry run program, and you can also use the graphic simulation function.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe