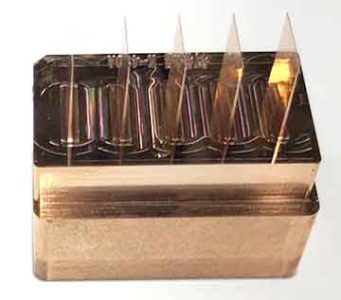

Mecanizado CNC de electrodo de cobre.

El electrodo de cobre de la máquina EDM, También conocido como mecanizado CNC del espejo de electrodo de cobre. Es una parte indispensable en el procesamiento de la máquina EDM.

Durante el mecanizado por electroerosión, el electrodo de cobre y la pieza de trabajo están conectados respectivamente a los dos polos de la fuente de alimentación de pulso. El voltaje del pulso aplicado al electrodo de cobre y la pieza de trabajo genera una descarga de chispa.. La temperatura instantánea de la descarga puede ser tan alta como 10,000 grados Celsius, y la alta temperatura hace que la superficie de la pieza de trabajo se vaporice o derrita parcialmente.

Electrodo de cobre de máquina de electroerosión.

Inmediatamente después del siguiente voltaje de pulso, Se genera una descarga de chispa entre el electrodo de cobre y la pieza de trabajo, y el proceso anterior se repite.

A través de innumerables descargas repetitivas de pulso, finalmente se procesa una forma correspondiente a la forma del electrodo. Por lo tanto, Mientras cambie la forma del electrodo de cobre, Se pueden procesar varios perfiles complicados.

En el mecanizado EDM, El papel del electrodo de cobre es transmitir pulsos de procesamiento y eliminar la pieza de trabajo con la pérdida mínima del electrodo de cobre en sí. Los materiales de electrodo de uso común son cobre, grafito, aleación de tungsteno de cobre, aleación de plateado-tungsteno, acero, latón, hierro fundido, etc..

Espejo electrodo de cobre

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe