Produktkategorien

Produkt Tags

10 Materialien für die CNC-Bearbeitung von Prototypen

Im Vergleich zum 3D-Druck, Der größte Vorteil von CNC-Prototypen ist der Reichtum und die Praktikabilität der Materialien. Der Hauptzweck des Prototyps besteht darin, die Machbarkeit des Produktdesigns zu überprüfen, Daher sind auch die Materialien des Prototyps sehr speziell. Die Produkte jedes Unternehmens sind unterschiedlich, und auch die Prototypenmodelle, die hergestellt werden müssen, sind unterschiedlich. daher, Auch die Produktionsmaterialien können unterschiedlich sein, Zu den wichtigsten Verarbeitungsmaterialien gehören jedoch die folgenden:

Im Vergleich zum 3D-Druck, Der größte Vorteil von CNC-Prototypen ist der Reichtum und die Praktikabilität der Materialien. Der Hauptzweck des Prototyps besteht darin, die Machbarkeit des Produktdesigns zu überprüfen, Daher sind auch die Materialien des Prototyps sehr speziell. Die Produkte jedes Unternehmens sind unterschiedlich, und auch die Prototypenmodelle, die hergestellt werden müssen, sind unterschiedlich. daher, Auch die Produktionsmaterialien können unterschiedlich sein, Zu den wichtigsten Verarbeitungsmaterialien gehören jedoch die folgenden:

2. PC: Material mit guter Festigkeit, Zähigkeit und Transparenz, Geeignet für die Herstellung von Linsen- und Feinstrukturteilen. Zusätzlich, Glasfasern werden hinzugefügt, um die Stahl- und Hitzebeständigkeit der Platine zu verbessern, Das kann zur Herstellung von Teilen verwendet werden, die in einer Umgebung mit hohen Temperaturen eine hohe Steifigkeit aufrechterhalten müssen. Der PC verfügt außerdem über die Brandschutzklasse UL94-V0;

3. PMMA: Nämlich Acryl, oder Plexiglas. Es ist ein gutes transparentes Teil, Das Material mit der besten Transparenz kann durch Oberflächenbehandlung wie Färben hergestellt werden, Galvanisieren, Sprühen, und Siebdruck. Die Schweißfestigkeit ist akzeptabel, aber Zerbrechlichkeit ist seine Schwachstelle, und es ist nicht für den Einsatz an gefährdeten Stellen wie Haken geeignet;

4. PP: Durchscheinendes Material, gute Schlagfestigkeit, ausgezeichnete Flexibilität, kann auf Produkte mit strengen Schlagfestigkeitsbedingungen angewendet werden. Wie zum Beispiel: Automobilzulieferer, halbfaltbare Verpackungskartons, usw.

5. PA66+GF30: PA66+GF30 ist kein Modell, Es handelt sich um einen allgemeinen Code für PA66-Kunststoffmaterialien mit 30% Glasfaser. Hohe Festigkeit, besondere thermische Stabilität, Hydrolysebeständigkeit, Geeignet für Autoteile, mechanische Teile, usw. Es wird als Abschirmung für mechanische Teile verwendet, die eine hohe Steifigkeit und Formstabilität erfordern. Flammschutzmittel aus rotem Phosphor zeichnen sich durch Langzeitstabilität und hervorragende mechanische Verarbeitungsleistung aus;

6. POM: Auf Chinesisch wird es Polymethin-Rohstoff genannt, auch als Polyoxymethin-Rohstoff bekannt. In der Prototypenindustrie wird es oft Saigang genannt. Die regelmäßige Molekülstruktur und Kristallinität machen seine physikalischen und mechanischen Eigenschaften zu hervorragenden physikalischen und mechanischen Eigenschaften, und es heißt Metall-Kunststoff. Im Prototypenmodell, Es ist für hochfeste Werkstücke geeignet, wie zum Beispiel Zahnräder, Wellen, Klammern, usw.;

7. Teflon: Der chemische Name ist Polytetrafluorethylen (Kurz gesagt: PTFE), was allgemein so genannt wird "Antihaftbeschichtung" oder "leicht zu reinigendes Material". Dieses Material ist säurebeständig, Alkalien, und verschiedene organische Lösungsmittel, und ist in allen Lösungsmitteln nahezu unlöslich. Gleichzeitig, PTFE zeichnet sich durch eine hohe Temperaturbeständigkeit aus, und sein Reibungskoeffizient ist sehr niedrig, Daher kann es zur Schmierung verwendet werden und ist eine ideale Beschichtung für die einfache Reinigung der Innenschicht von Wasserleitungen;

8. Aluminiumlegierung: Aluminiumlegierung ist das am häufigsten verwendete Nichteisenmetall-Strukturmaterial in Prototypenmodellen, und ist in der Luftfahrt weit verbreitet, Luft- und Raumfahrt, Automobil, medizinisch, und Schiffsprototypenmodelle. Derzeit, Aluminiumlegierung ist die am häufigsten in Prototypen verwendete Legierung. Die Vorteile liegen in der einfachen Verarbeitung und Umformung, gute Steifigkeit, und satte Anodenfärbung;

9. Magnesiumlegierung: geringes Gewicht und gute Festigkeit, Es ist ein beliebtes Material für 3C-Verbraucher. Der Nachteil besteht darin, dass Magnesium ein brennbares Metall ist, und die Kontrolle der Umgebungsbedingungen ist während der Bearbeitung sehr wichtig. Der Herstellungsprozess von Modellen aus Magnesiumlegierung ist äußerst gefährlich, und es gibt viele Bearbeitungsprozesse nach dem Druckguss während der Produktion, Das ist ein kostspieliges Bewerbungsmaterial;

10. Messing: Messing ist eine Legierung aus Kupfer und Zink. Messing, das aus Kupfer und Zink besteht, wird gewöhnliches Messing genannt. Wenn es sich um eine Vielzahl von Legierungen handelt, die aus zwei oder mehr Elementen bestehen, es wird Spezialmessing genannt. Messing hat eine hohe Verschleißfestigkeit. In Prototypenmodellen wird häufig Messing verwendet, um Materialien zu ersetzen, die schwer zu gravieren und zu fräsen sind, wie zum Beispiel Edelstahl. Nach dem Polieren und Galvanisieren, Die Oberflächenwirkung und Haptik kommen denen von Edelstahl sehr nahe.

CNC-gefräster ABS-Prototyp

CNC-Bearbeitungs-PC-Prototyp

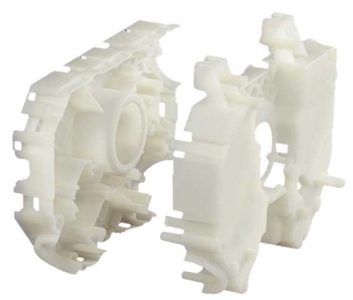

CNC-Bearbeitung von PP-Rapid-Prototypen

Schnelles Prototyping von Aluminiumlegierungen

CNC-Bearbeitung von POM-Rapid-Prototyping

Kontaktiere uns

Warten auf Ihre E-Mail, Wir werden Ihnen innerhalb von 24 Stunden antworten 12 Stunden mit wertvollen Informationen, die Sie brauchten.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe