Das Bohren erfolgt im halbgeschlossenen CNC-Schnitt. Beim Bohren von Titanlegierungen ist die Schneidtemperatur sehr hoch, Der Rückprall nach dem Bohren ist groß, Die Bohrspäne sind lang und dünn, leicht zu kleben und nicht leicht zu entladen. Beim Bohren von Titan kommt es häufig zum Verbiss des Bohrers, verdrehte, und so weiter. daher, Der Bohrer muss eine hohe Festigkeit und gute Steifigkeit aufweisen, und die chemische Affinität zwischen dem Bohrer und der Titanlegierung ist gering. Am besten verwenden Sie Hartmetallbohrer, Am häufigsten werden derzeit jedoch noch Spiralbohrer verwendet, nachdem einige Maßnahmen zur Verbesserung ergriffen wurden, es können auch bessere Ergebnisse erzielt werden.

(1) Improve drill bits: In order to meet the needs of titanium alloy CNC drills, the following improvement measures should be taken for twist drills:

Increase the top angle of the drill bit, 2Ф=135°~140°; Increase the clearance angle at the outer edge of the drill bit, taking 12°~15°; Increase the helix angle, p=35°~40°; Increase the thickness of the drill bit core and take (0.22~0.4) do (do is the diameter of the drill bit).

Use “S” shape or “X” shape to sharpen the chisel edge of the drill, the chisel edge length b=(0.08~0.1)do, while ensuring that the symmetry of the chisel edge is ≤0.06 mm. Both types of chisel edges can form a second cutting edge, which plays a role of chip separation and reduces the axial force during drilling.

The most commonly used is to grind a cutting edge shape suitable for drilling titanium alloys on a twist drill. Das ist, the titanium alloy group drill, the shape of the cutting part is shown in Figure 7-1. In der Figur, the outer and inner cutting edge angles 2φ and 2φ′ are 130°~140° when the drill diameter do>3~10mm, and 125°~140° when do>10~30 mm;

The clearance angle α of the outer edge is 12°~18° when do>3~10 mm, and 10°~15° when do>10~30 mm;

Chisel edge angle ψ=45°;

Internal cutting edge angle γτ=-10°~-15°;

Inner blade angle τ=10°~15°;

The relief angle of the arc blade aR=18°~20°.

Relevant parameters and drilling amount of titanium alloy group drill

See Table 7-8 and Table 7-9 for the relevant parameters and drilling quantities of titanium alloy group drills.

Four guiding blades are made on the drill bit to increase the section moment of inertia of the drill bit, improve rigidity, and naturally form two auxiliary cooling grooves. The durability is about 3 times higher than that of standard drills, and the cutting temperature is reduced by about 20%. Gleichzeitig, the amount of hole expansion is reduced due to the stable guiding. Zum Beispiel, the hole expansion of a Ф3 mm four-flute drill bit is 0.03~0.04 mm, while the standard drill bit is 0.05~0.06 mm.

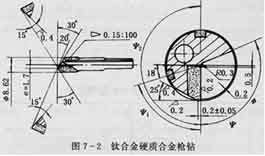

(2) Choose a suitable gun drill: When drilling deep holes with a titanium alloy aspect ratio greater than 5, when the hole diameter is less than or equal to 30 mm, a cemented carbide gun drill is generally used, wie in der Abbildung gezeigt 7-2; When the hole diameter is greater than 30 mm, a cemented carbide BTA drill bit or jet suction drill is used. Use the gun drill shown in Figure 7-2 to drill the hole of TC4, the hole depth is 204 mm (length-to-diameter ratio is about 26), and the surface roughness Ra is 1.6 μm. The productivity is increased by 4 mal, the chips are in the shape of “Plum” oder “C”, and chip removal is normal.

Water-based cutting fluids should not be used when drilling deep holes, because water may form steam bubbles on the cutting edge at high temperatures, which may easily generate built-up edges and make drilling unstable. It is advisable to use N32 engine oil and kerosene, the ratio of which is 3:1 oder 3:2, and sulfurized cutting oil can also be used.

Cemented carbide gun drills for drilling titanium alloys

When using a carbide gun to drill deep holes with a length-to-diameter ratio greater than 30. Vibration drilling by applying vibration of less than 100 Hz in the axial direction can make the surface roughness Ra of the workpiece 0.3 μm and increase the productivity by 5 mal. The specific parameters are Vc=17 m/min, f=0.033 min/r, the amplitude is 0.07 mm, the frequency is 35 Hz, the roundness of the workpiece is 4 μm, and the surface roughness Ra is 0.33 μm.

(3) Choose the right cutting fluid: Electrolytic cutting fluid can be used when drilling shallow holes. Its ingredients are sebacic acid 7%-10%, triethanolamine 7%-10%, glycerol 7%-10%, boric acid 7%-10%, sodium nitrite 3%-5%, and the rest is water.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe