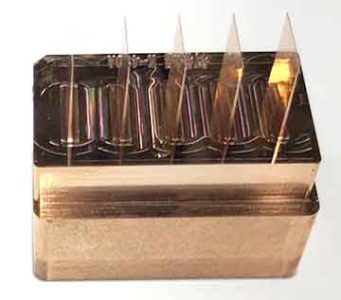

CNC-Bearbeitung von Kupferelektroden

Die Kupferelektrode der Erodiermaschine, Auch als CNC-Bearbeitung von Kupferelektrodenspiegeln bekannt. Es ist ein unverzichtbarer Bestandteil bei der Bearbeitung von Erodiermaschinen.

Während der Erodierbearbeitung, Die Kupferelektrode und das Werkstück sind jeweils an die beiden Pole der Impulsstromversorgung angeschlossen. Die an der Kupferelektrode und am Werkstück anliegende Impulsspannung erzeugt eine Funkenentladung. Die momentane Temperatur der Entladung kann bis zu hoch sein 10,000 Grad Celsius, und die hohe Temperatur führt dazu, dass die Oberfläche des Werkstücks teilweise verdampft oder geschmolzen wird.

Kupferelektrode der Erodiermaschine

Unmittelbar nach dem nächsten Spannungsimpuls, Zwischen der Kupferelektrode und dem Werkstück entsteht eine Funkenentladung, und der obige Vorgang wird wiederholt.

Durch unzählige sich wiederholende Impulsentladungen, Eine der Form der Elektrode entsprechende Form wird abschließend bearbeitet. daher, solange sich die Form der Kupferelektrode ändert, Es können verschiedenste komplizierte Profile bearbeitet werden.

Bei der Erodierbearbeitung, Die Aufgabe der Kupferelektrode besteht darin, Bearbeitungsimpulse zu übertragen und das Werkstück mit minimalem Verlust der Kupferelektrode selbst zu entfernen. Üblicherweise verwendete Elektrodenmaterialien sind Kupfer, Graphit, Kupfer-Wolfram-Legierung, Silber-Wolfram-Legierung, Stahl, Messing, Gusseisen, usw.

Spiegelkupferelektrode

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe