Surface treatment technology and function of CNC machined parts, Surface finish cost

For each product, a specific surface treatment for CNC machining components can be carried out. Imidlertid, the surface finishes of the product tend to increase the corresponding cost.

Some surface treatments, such as high polish, aim to remove any trace of the machining process.

F.eks:

Surface Finishing of CNC Machined Parts

The surface finish can produce a reflective surface.

Matte surface treatment or sandblasting eliminates reflections.

Mirror polish on clear plastic to look like glass.

Finishing painting and staining may change the color of the product.

Laser engraving can decorate your products.

By printing, you can print letters or patterns on the product after it is finished.

Soft surface treatment involves the application of a soft rubber-like coating over the product.

Some surface treatments play an essential role in making your products last longer. These include galvanized, anodized, and brushed.

Some companies may allow you to combine different finishes on their products. For eksempel, you may be able to get a laser etched glossy polished surface, although this may cost more.

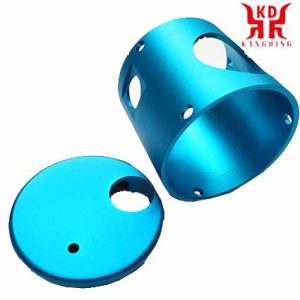

Finishing of aluminum alloy parts

What is CNC machining surface finish and finishing?

CNC machining surface finish can be divided into:

Oxidation processing,

Paint processing,

Galvanisering,

Polished,

Wire drawing,

Sandblast,

Oil spraying,

Serigraphy

Pad printing,

Galvanisering,

Uv

Metal corrosion processing

1. Oxidation processing: When the price of the CNC machining suppliers produces finished CNC machining parts (mainly aluminum CNC machining parts), it uses an oxidation process to harden the surface of the CNC machining product and make it difficult to wear.

2. Spray paint processing: The CNC Service Company uses spray paint processing when producing large CNC precision machining parts. Spray paint processing prevents CNC machining components from rusting, såsom daglige fornødenheder, electrical cabinets, crafts, etc.

3. Galvanisering: Electroplating is also the most common processing technology for CNC machining part processing. The surface of the CNC machined components is galvanized using modern technology to ensure that it will not mold or rub off with prolonged use. The standard processing of electroplating includes screws, stempling af dele, cells, auto dele, små tilbehør, etc.

Overfladebehandling af kobber

4. Polished: Use polishing materials for polishing, wax polishing, copper water rub, etc., for manual polishing. Polish the sharp corners on a smooth face so as not to cause harm to the human body during use.

5. Brushing: Draw some strokes on the surface of aluminum or steel parts or other products to make the sample feel better. Plastic wire drawing is usually sprayed with a thick coat of paint and then processed by this process. The effect is worse than that of metal CNC aluminum machining parts. The texture is worse than metal parts.

6. Sandblæsning: There is a lot of residual plastic in the computer gong sample, which is very difficult to manipulate manually, especially when there are many holes or multiple buckles, which is very time consuming.

So use a sandblasting machine. The residual plastic falls off. Aluminum CNC machining parts or other metal parts are knife lines that can cover the surface. Some customers also require sandblasting and then oxidation to give the body a robust, grainy metal texture.

The sand is delicate glass beads, distinguished by patterns (for eksempel, No. 60 is coarse sand and No. 200 is fine apple sand)

7. Oil injection: spray the products we have manufactured according to customer requirements. Our site is a dust-free oil injection room and the best oil is used. (Injection can be sprayed with rubber oil, gloss varnish, Light semi-matte, matte, baking and different paint colors)

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe