Produktkategorier

Produkt Tags

Kvalitetsanalyse af trykstøbning af aluminium

Fejlanalyse af trykstøbning af aluminium:

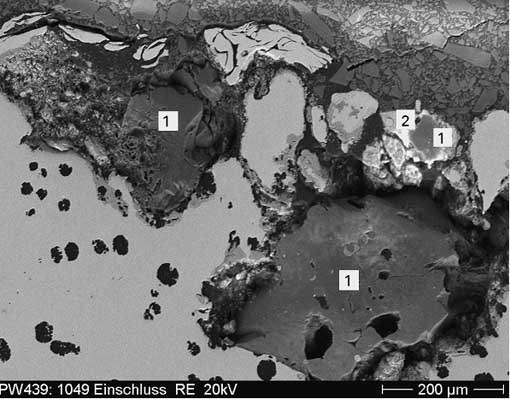

Oxidation og slagge inklusion af aluminium trykstøbegods.

Defektkarakteristika for aluminiumsstøbegods: oxideret slagge er for det meste fordelt på den øvre overflade af støbegodset, ved hjørnerne af støbeformen, hvor der ikke passeres luft. Frakturerne er for det meste råhvide eller gule, og findes ved røntgenstråler eller mekanisk behandling. Det kan også findes i alkalisk vask, bejdsning eller anodisering

Defektkarakteristika for aluminiumsstøbegods: oxideret slagge er for det meste fordelt på den øvre overflade af støbegodset, ved hjørnerne af støbeformen, hvor der ikke passeres luft. Frakturerne er for det meste råhvide eller gule, og findes ved røntgenstråler eller mekanisk behandling. Det kan også findes i alkalisk vask, bejdsning eller anodisering

cause:

1. The charge of aluminum die-casting is not clean, and the amount of charge used is too much

2. Poor gating system design

3. The slag in the alloy liquid is not cleaned

4. Improper pouring operation brings in slag

The standing time sufficient modification after refining

Prevention method:

1. The charge should be sand-blown, and the amount of charge used should be appropriately reduced

2. Improve the design of the gating system to increase its slag retaining ability

3. Use proper flux to remove slag

4. Pouring should be stable and pay attention to slag retention

5. The alloy liquid should stand for a certain period of time after refining before pouring

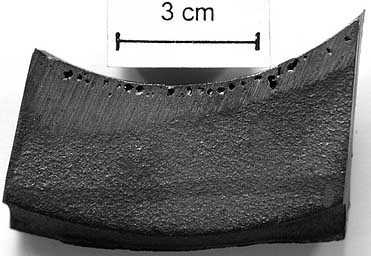

Pores and bubbles appear in aluminum die castings

Defect characteristics: The pores in the wall of aluminum castings are generally round or oval, with a smooth surface, usually shiny oxide skin, sometimes oily yellow. Surface pores and bubbles can be found by sandblasting, and internal pores and bubbles can be found by X-ray fluoroscopy or mechanical processing. The bubbles appear black on the X-ray film.

cause:

1. The casting alloy is not stable, and gas is involved

2. Det (core) sand is mixed with organic impurities (such as coal cuttings, grassroots horse manure, etc.)

3. Poor ventilation of mold and sand core

4. There are shrinkage holes on the surface of cold iron

5. Poor gating system design

Prevention method:

1. Correctly control the pouring speed to avoid getting involved in gas.

2. No organic impurities should be mixed into the molding (core) sand to reduce the gas evolution of the molding material

3. Improve the exhaust ability of (core) sand

4. Correct selection and treatment of cold iron

5. Improve gating system design

Shrinkage and looseness of aluminum die castings

cause:

1. Poor feeding effect of cavity riser

2. Die-casting charge contains too much gas

3. Overheating near the runner in the cavity

4. There is too much moisture in the sand cavity and the sand core is not dried

5. Coarse alloy grains

6. Improper position of the casting in the mold

7. Pouring temperature is too high, pouring speed is too fast

Prevention method:

1. The cavity is filled with molten metal from the riser and the riser design is improved

2. Die-casting charge should be clean and non-corrosive

3. A riser is set at the shrinkage porosity of the casting, and cold iron or cold iron is placed in combination with the riser

4. Control the moisture of the molding sand and dry the sand core

5. Take measures to refine material grains

6. Improve the position of the casting in the mold to reduce the pouring temperature and pouring speed

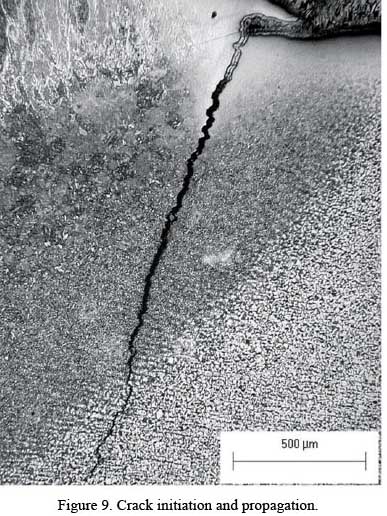

Four, there are cracks in die casting

Defect characteristics of aluminum die casting

Casting crack

Cracks develop along grain boundaries, often accompanied by segregation. It is a kind of cracks formed at higher temperatures that are easy to appear in alloys with larger volume shrinkage and castings with more complex shapes.

2. Heat treatment cracks

Due to heat treatment overburning or overheating, it often presents transcrystalline cracks. The alloys with large stress and thermal expansion coefficient are often cooled excessively. Or when there are other metallurgical defects

cause

1. The casting structure design is unreasonable, there are sharp corners, and the wall thickness changes too much

2. Sand mold (core) poor concession

3. Local overheating of the mold

4. Pouring temperature is too high

5. It is too early to take out the casting from the mold

6. The heat treatment is overheated or burned, and the cooling rate is excessive

Prevention method

1. Improve the structural design of castings to avoid sharp corners, strive for uniform wall thickness and smooth transition

2. Take measures to increase the concession of sand mold (core)

3. Ensure that all parts of the casting are solidified at the same time or sequentially, and improve the design of the gating system

4. Appropriately lower the pouring temperature

5. Control the mold cooling out time.

6. The thermal correction method is used when the casting is deformed.

7. Correctly control the heat treatment temperature and reduce the quenching cooling rate

The problem is that aluminum castings have loose structure, high porosity, and contain a variety of metallic and non-metallic impurities. After dyeing, the anodic oxide film is prone to white spots, and the quality of the anodic oxide film on aluminum castings is difficult to guarantee. In this regard, relevant experts said that the following methods can be used to avoid this problem:

the first, Use high voltage and high current density impact method. In the early stage of anodizing, high voltage and high current shocks are used to connect the large and small “blocks” originally divided by impurities into pieces by high current shocks.

second, Casting surface grinding method. Grinding can fill the pores of the casting with the ground aluminum powder and act as a bridge connecting the blocks separated by impurities.

third, Shot peening of casting surface. Before the trial blasting method I round a hammer, the intention is to make the barrier gap “block” is closed by tapping, in order to connect to the sheet, the effect is significant results. Using these methods can effectively avoid the appearance of white spots after dyeing the anodized film of aluminum castings, thereby ensuring its quality.

Advantages of casting

1. It can produce parts with complex shapes, especially blanks with complex cavities (such as heating)

2. Wide adaptability, metal materials commonly used in industry can be cast. A few grams ~ hundreds of tons.

3. Wide sources of raw materials. The price is low. Scrap, scrap, chips

4. The shape and size of the casting is very close to that of the part, reducing the amount of cutting, which is less and without cutting.

Pores and bubbles of castings

Pores and bubbles of castings

Krympning og løshed af aluminiumsstøbegods

Surface treatment of aluminum castings

Krympning og løshed af aluminiumsstøbegods

Kontakt os

Venter på din e-mail, vi vil svare dig inden for 12 timer med værdifuld information, du havde brug for.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe